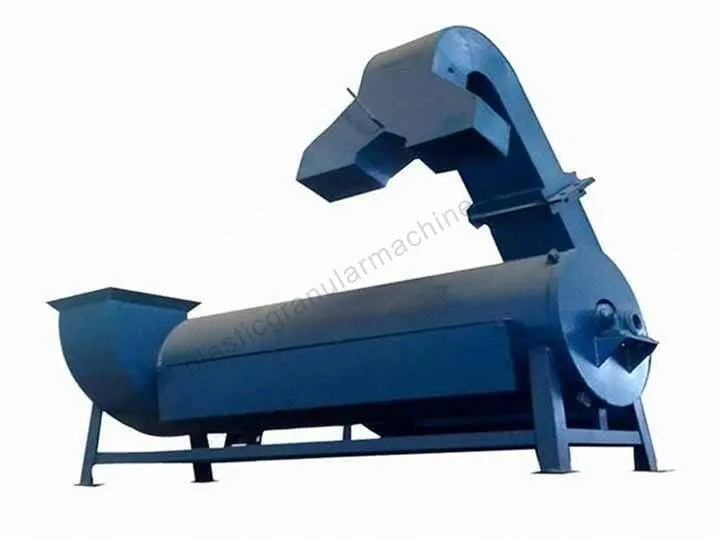

PET Bottle Trommel Screen Machine

| Brand | Shuliy Machinery |

| Application | PET bottle recycling plant |

| Trommel Length | 4500㎜ |

| Material | Carbon Steel |

| Warranty | 12 months |

You can now ask our project managers for technical details

Tumbler screens are equipment used in the plastic bottle recycling factory to effectively purify plastic waste through screening and sorting, providing a clear and organized material base for subsequent processing steps.

Introduction of trommel screen for plastic recycling

A trommel screen usually consists of a main screen frame, an inlet, a drum, a motor and drive system, a screen mesh and a slag outlet.

Through the rotating drum and reasonably designed screen mesh, the tumbler screen makes the plastic garbage rolling and turning, sifting off the debris and non-compliant raw materials.

Why do you need a PET bottle trommel screen machine?

Overall, the use of trommel screens in plastic bottle recycling lines plays a pre-treatment role and helps to improve recycling efficiency and the quality of PET flakes. The following points will explain the specific details.

- Size Screening: Tumbler screens can be used to screen plastic bottles of different sizes, separating large, medium and small sized bottles. This helps in the subsequent processing steps, ensuring that each size of bottle can be fed into the appropriate equipment for processing.

- Removal of Impurities: PET bottle tumbler screens are effective in removing impurities such as stones, metals, etc. from plastic waste. This helps prevent these contaminants from damaging other recycling equipment and improves the efficiency of the entire recycling process.

- Purification of materials: Through the tumbler screen, the initial purification of plastic bottle waste can be realized, removing surface attachments, soil and so on. This helps to improve the quality of the final product and ensures that the recycled plastic meets the criteria for reuse.

Related plastic bottle recycling line

The PET plastic bottle recycling crushing and washing line adopts an advanced process to fragment waste PET plastic bottles through a crusher, which is subsequently washed by a washing machine to remove pollutants, and ultimately through a drying system to remove water, resulting in clean and dry PET flakes.