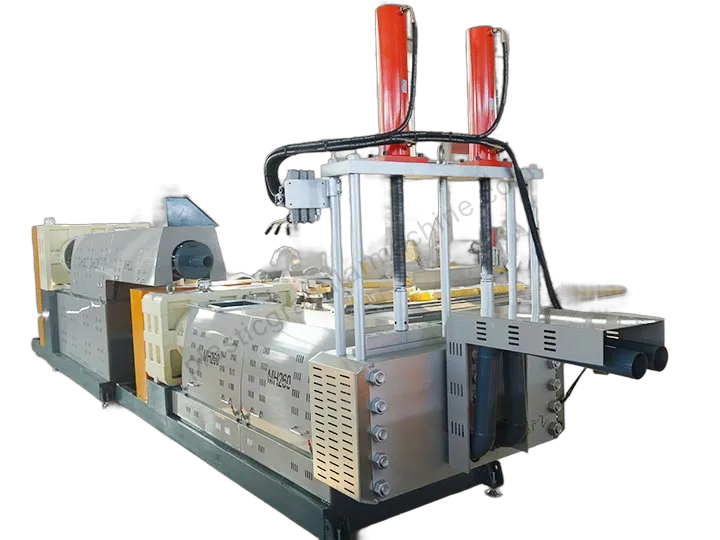

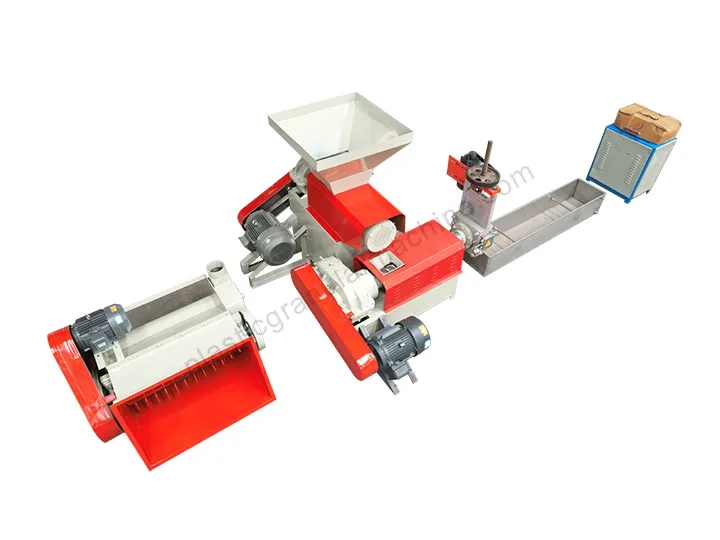

EPE Plastic Foam Granulator

| Model | SL-160 |

| Raw Materials | EPE Foam, EVA, PE film, etc. |

| Final Products | Granules as required size |

| Capacity | 100~250kg/h |

| Power | 30KW |

| Feed Inlet Size | 780mm x 780mm |

| Warranty | One year |

| Technical Support | Operation guides, on-site installation, etc. |

You can now ask our project managers for technical details

EPE plastic foam granulator is specially used to process the foam made of EPE into granules. The final plastic granules are neat in size and uniform in color, and have received good comments from the market.

Advantages Of The EPE Foam Extrusion Machine

- Wide Range of Application: Customized EPE foam granulators can effectively meet various scales of EPE pelletizing production.

- Easy to Operate: Equipped with intelligent cabinet, it can control the production progress in real time and stop when stopped.

- High Economic Efficiency: good quality of finished particles, high economic value, low maintenance cost of the pelletizer.

The advantages of the EPE extrusion machine are more than that, let’s continue to explore its secrets together!

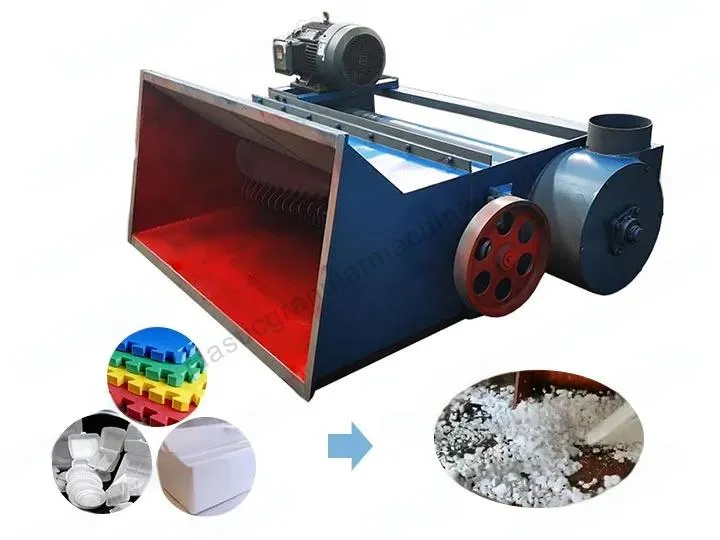

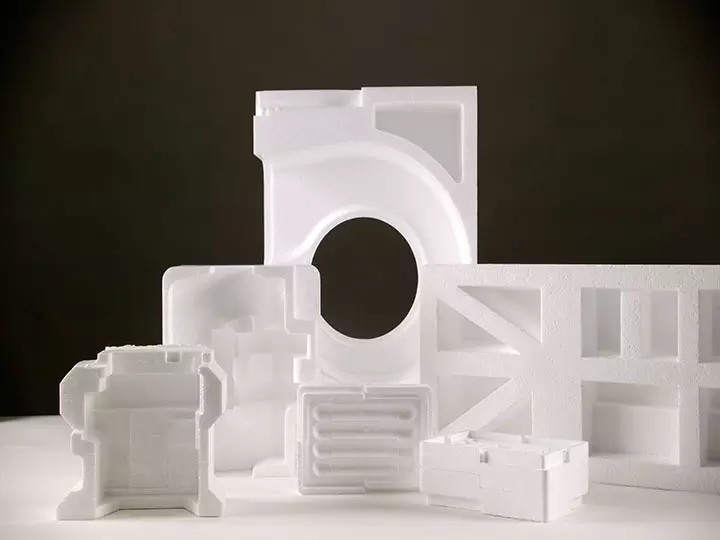

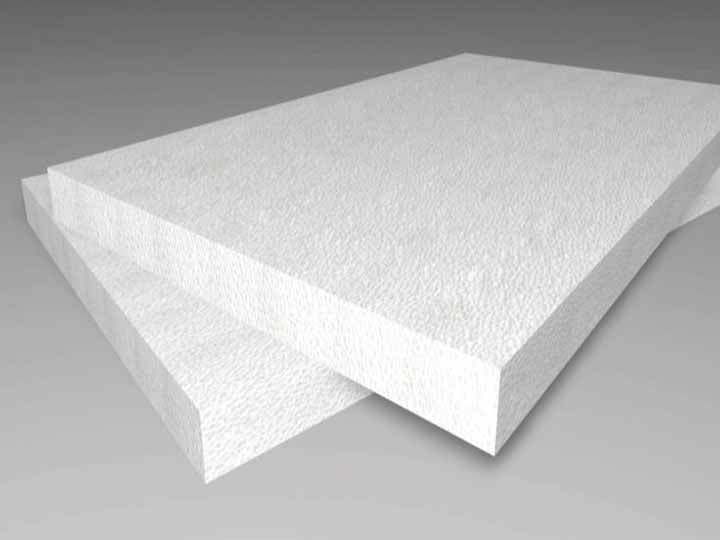

Raw Materials of Plastic Foam Granulator

- Packaging material: EPE foam is widely used in packaging, especially for fragile items such as electronic products, glass products, ceramics, etc.

- Insulating material: Due to its insulating properties, EPE foam can be used in construction and engineering, as an insulating material for roofs, walls and other parts.

- Packaging filler: Used as parcel and filler material to fill boxes, and parcel items and protect goods from damage in transportation.

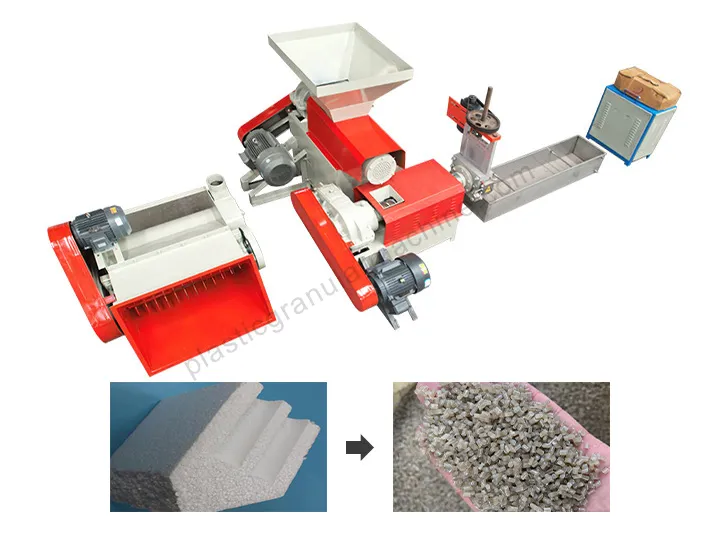

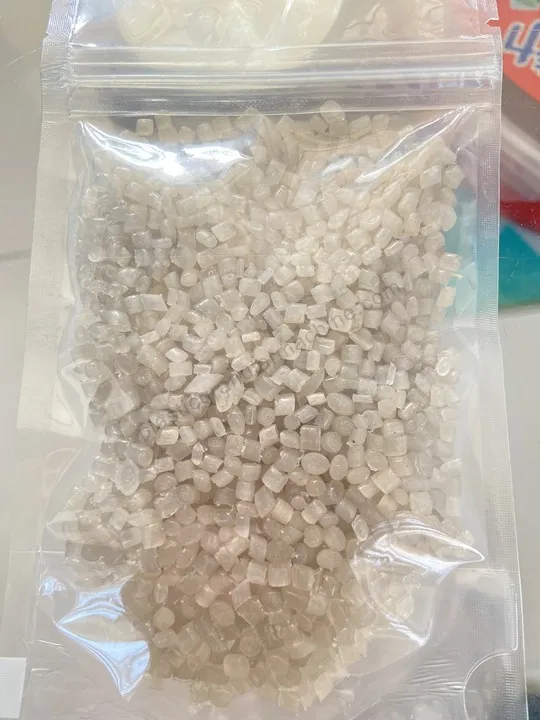

End Products of EPE Plastic Foam Granulator Machine

Our plastic foam granulators can produce high-quality plastic pellets stably even under harsh production environments. The end products can be used to manufacture new plastic products and have high economic values.

EPE Granulator Machine Working Principle

Crushing: Once the foam enters the EPE granulator machine, it first passes through a crushing system. This step is designed to break large pieces of foam material into smaller chunks for subsequent processing.

Heating and melting: The crushed foam blocks are passed through a heating system that melts them into a fluid state. This step helps to change the physical properties of the foam material, making it easier to process.

Extrusion: The partially melted foam material is fed into the extrusion system and finally extruded in strips by the die.

Cooling: The plastic strip passes through a cooling tank to reduce its temperature, ensuring stability and curing of the plastic.

Cutting: The cooled plastic strip passes through a pelletizer, where it is cut into the desired length of pellets.

Working Video of Plastic Foam Pelletizing Machine

This video shows how an EPE plastic foam granulator works in the complete styrofoam recycling line. Transforming bulky waste foams into high-quality recycled pellets, this styrofoam pelletizer does a good job!

In Summary

If you have any questions about epe recycling or need the foam pellet-making machines, please feel free to contact us. Our foam pelletizing machines’ wide application range and large capacity make them suitable for all production sizes. If you have special needs, we can also provide customized machines.