Plastic Film Recycling Line Machine

| Recycle Capacity (kg/h) | 100-500 |

| Recycle Materials | PP, PE film and bag production waste, HDPE soft irrigation pipe, printed bag, Film/bag cut offs, plastic regrinds, wovwn sack, plastic lumps/bulks, leno bags, agriculture film, Blow-molded products |

| Material type | PP, PE, HDPE, LLDPE, LDPE. PVC |

| Core Equipment | Crusher, Granulator |

| Optional equipment | Screw conveyor, Belt conveyor, Auto feeder, pellet packing machine |

| Warranty | 12 Months |

| After Warranty Service | Video Technical Support, Online Support, Field Maintenance and Repair Service |

You can now ask our project managers for technical details

Plastic film recycling line is a production line for recycling all kinds of plastic films, such as plastic bags and woven bags. Our plastic recycling line is very suitable for the crushing, cleaning, drying, granulation and packing of waste pe/pp films. With the help of this production line, you can easily get clean plastic pellets. Eventually, these waste PP/PE films become renewable and reusable materials.

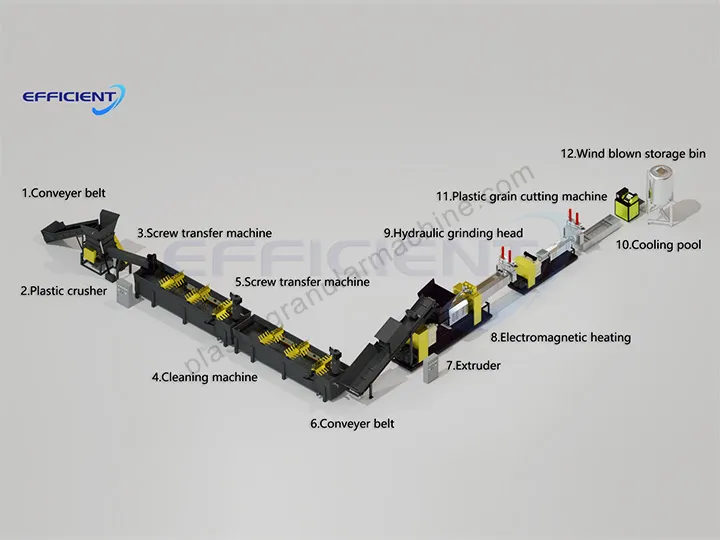

What is the workflow of the plastic film recycling line?

First, put the waste plastic film on the belt conveyor. Then the belt conveyor will send the plastic film into the plastic film crusher for crushing and cleaning. Because there are many impurities in waste films, we need to be clean it again. Then dry the cleaned plastic products. Next comes the most important granulation process. After granulation, the plastic pulp needs to be cooled. Finally, cut the plastic strip into small plastic particles for packaging. This is the complete workflow of the plastic film recycling line.

Introduction of plastic film recycling machine

Efficient’s high-efficiency plastic film recycling machine is designed for the reprocessing of PE polyethylene (HDPE, LDPE, LLDPE) and PP polypropylene flexible packaging material, printed and non-printed. We recommend this line for blow film producers, woven sack producers, and printed zipper bag producers. They can recycle the defective film production waste and film cut-offs by our recycling machines. The final pellets can be directly used un the film production line. For film producers, they can reduce material costs.

In addition to in-house (post-industrial) film waste, the recycling system is also able to process post-consumer waste. The common recycle materials are bag scraps, used garbage bags, agricultural films, food packaging, jumbo bags, shrink and stretch films raffia bags, and PP woven bags.

Core recycle equipment of the film pelletizing line

Plastic film crusher

Plastic film crusher is a special machine for crushing plastic film. It is also the first major equipment of plastic film recycling line. The rotary cutter inside the plastic crusher can crush materials into small pieces in a short time. At the same time, this machine can also clean plastic debris. This means that it has the function of crushing and cleaning. In addition, our machines are made of high-quality steel. The blade is made of si2mn. Therefore, the machine crusher is durable.

Plastic film washing machine

The plastic film washing machine is used to clean plastic film again. We all know that there are many impurities in the recycled plastic film. Unclean raw materials will seriously affect the subsequent granulation effect. Therefore, we specially configured a plastic film cleaning tank to clean the plastic film again. The toothed agitator inside the machine can push the plastic debris forward. Therefore, this can further reduce human resources.

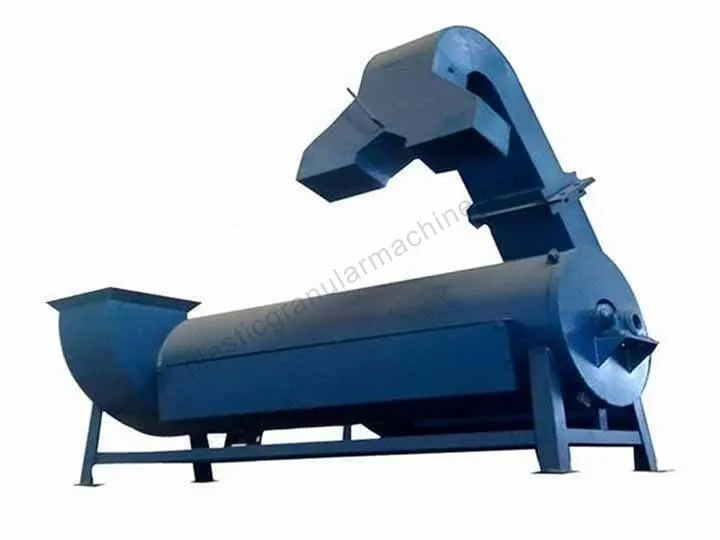

Plastic film dehydrator

In Efficient plastic machinery, we have horizontal plastic dehydrators and vertical dehydrators. If you have a small plant, you can choose a vertical dehydrator. The vertical dryer has the functions of powerful cyclone cleaning, automatic conveying, high-speed centrifugal dehydration, etc. Therefore, it can dry materials in a short time. With the help of a vertical dehydrator, the water content of the plastic film can be less than 2.5%.

Plastic film granulator

Plastic film granulator is the key equipment for the plastic film recycling line. It can melt PP and PE plastic films and extrude them into strips. Plastic granulator adopts automatic temperature control and electromagnetic heating system. Therefore, it has the characteristics of less electricity, no pollution, and a high degree of automation. The following is the production process of the machine.

Materials enter the plastic granulator from the feed inlet. Then the material melts under the action of a high-temperature heating ring. Then the molten material flows out of the outlet of the main machine and into the auxiliary granulator machine. Under the extrusion of the auxiliary machine, the plastic strip is extruded from the die of the machine head.

Pellet cutting machine

The plastic film granulator can melt the plastic film and extrude the plastic strip. The pellet-cutting machine is a machine that cuts plastic strips into plastic particles. The purpose is to facilitate storage. The cutter of the plastic pellet cutting machine is made of cemented carbide. Therefore, it has high wear resistance.

Advantages of Efficient plastic film recycling machine

- Unique customized service. We can help you design a pellet production line from 200kg/h to 3000kg / h.

- The energy consumption of the whole production line is low.

- We can provide you with low-budget solutions for customers with low-budget costs.

- The automatic plastic film recycling machines have the characteristics of high production efficiency and labor cost saving.

- 10 years of experience in the production of plastic recycling equipment.

Video of plastic film recycling line

What kind of plastic film can be recycled?

- Agricultural film. The agricultural film mainly includes mulch film and greenhouse film. The mulching film is mainly PE film. The shed formwork has PE, PE/EVA, and PVC films.

- Packaging film. The materials of packaging film include cellophane, PE, PVC, PP, EVA, PVDC, PA, PET and various composite films.

- Aluminum plastic composite film. Aluminum plastic composite films include Bopp/ aluminum, pe/ aluminum, etc. They are the raw material for the packing of various foods.

- PET film. In the plastic industry, PET is the main raw material for film and bottle.

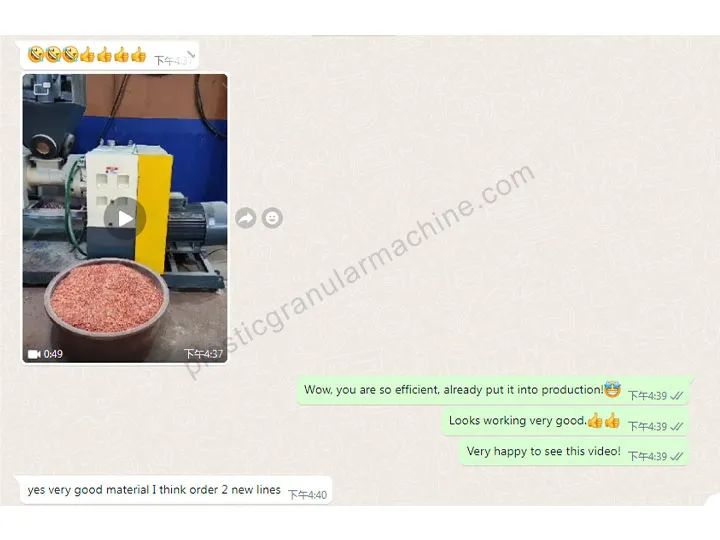

Successful cases of plastic pelletizing recycling machine

We have successfully completed many plastic pelletizing recycling machine deals and we have partners all over the world. We proudly serve many countries including Oman, Nigeria, Saudi Arabia, Kenya, and Cote d’Ivoire, and have made positive contributions to the plastic recycling industry in these regions.

The customer from Cote d’Ivoire bought Efficient Machinery plastic pelletizing machine for recycling HDPE and PP plastic bottles. Now the whole plastic pelletizing line has been running successfully. The following video is taken by the workers in Cote d’Ivoire factory.

Several months ago, a customer from Oman purchased a plastic pelletizer machine from Efficient Group. Now the machines have already arrived in Oman.

Get your own amazing plastic recycling plant!

When our customers receive our pelletizing machines, they express a high level of satisfaction. Some customers even recorded feedback videos specifically for us, sharing their affirmation of the machine’s performance and effectiveness.

If you are interested in plastic film recycling machines, welcome to contact us now! We will contact you and send you the machine details in 24 hours.