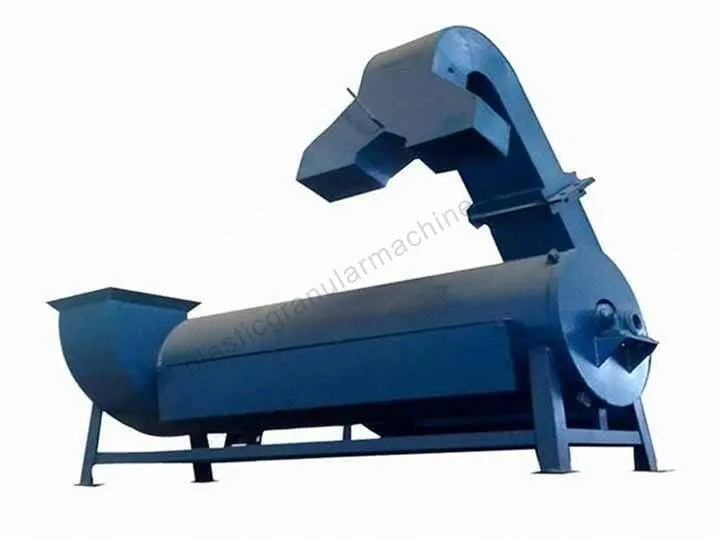

PET Flakes Washing Float Sink Separation Tank Machine

| Item Name | Washing Tank |

| Suitable Material | Variety |

| Model | Small |

| Motor Power | 3kw |

| Size | Can be customized |

| Scope of Application | For Washing PP. PE. PET |

| Usages | Used for Cleaning Plastic Flakes |

You can now ask our project managers for technical details

PET flakes washing machine is one of the machines of plastic bottle recycling line. It plays a very important role in the whole PET bottle washing line. Because we all know that waste plastic bottles contain a lot of impurities and stains. Therefore, in order to get high-quality plastic flakes, we need to use a PET flakes washing plant to clean the crushed plastic flakes.

Why Do You Need a PET Bottle Washing Machine?

The PET bottle washing machine is also called sink float tank. The plastic beverage bottles are contained of two parts: PET bottle body and PP caps. The different materials should be processed by different ways. Therefore, plastic recycling plants should separate the PP from PET.

It can be completed by the differences in densities. The density of water is exactly 1g/cm, in the common plastic only PP and PE density is less than 1.0, so the water can float in the water is a PP bottle cap, PET material because the density is greater than the water will sink to the bottom. So that’s why we also call a PET bottle washing machine a plastic floating separation tank.

Key Features of The Plastic Sink Float Tank?

- We are pleased to announce that the PET flakes washing machine has been upgraded, lengthened, and deepened, which has resulted in more effective precipitation and separation of impurities.

- In addition, we have equipped it with a water recycling system, which will help to reduce water consumption and operation costs.

- The plastic bottle sink float tank is capable of handling a variety of PET bottle fragments, of different sizes and shapes, with a wide range of adaptability.

- The plastic bottle washing process is straightforward and the results are impressive, with a high level of purity in the rPET.

Plastic Floating Separation Tank Video

In this video, you can see how a PET flakes washing machine works. Whatever questions you have, please feel free to consult us.

What Are the PET Flakes Washing Processes?

The PET flakes washing machine is equipped with multiple toothed plates. When the machine is working, it will be filled with clean water. The toothed plate rotates and pushes the plastic flakes forward. The rotating gear will clean the plastic flakes and remove the impurities in the plastic chips.

In order to get a better cleaning effect, you can also add detergent to the tank pontoon. Therefore, the plastic flakes washing process in this step is to clean the plastic flakes by mixing.

How To Clean Plastic Flakes for Recycling?

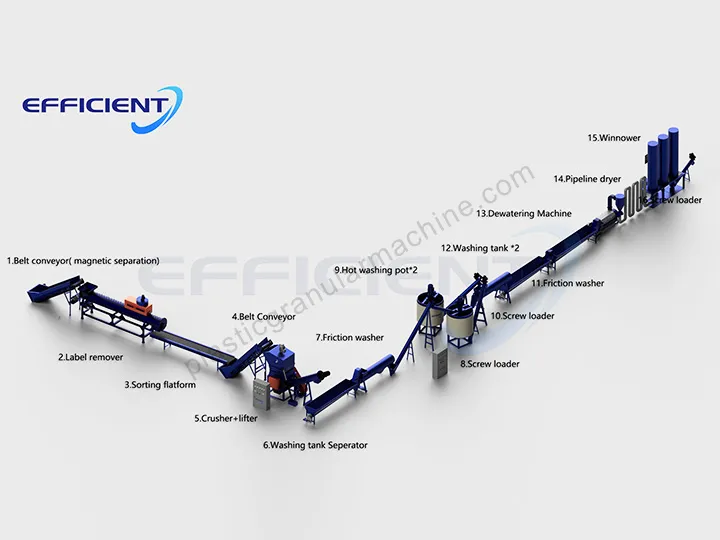

In the whole plastic bottle recycling line, we need more than just sink float plastic separation. For a better cleaning effect, a plastic friction cleaning machine and a hot water washing machine is also needed. The plastic friction cleaning machine can clean the greasy dirt and other stains on the plastic debris. In addition to cleaning plastic debris, the hot water washing machine also has the function of disinfection. Under the action of these three plastic cleaning equipment, we can get clean plastic fragments.

If you want to learn more, please feel free to contact us and view the below website:

Affordable Plastic Bottle Washing Machines for Your Plants

Parameters of Plastic Float Sink Tank

| Item name | Plastic float sink tank | Suitable material | Variety |

| Model | Small | Motor power | 3KW |

| Size | Can be customized | Customized | Yes |

| Scope of application | For washing PP, PE, PET | Usages | Used for cleaning plastic flakes, separating PP caps and PET chips |

The parameters of the small plastic PET flakes washing machine are mentioned in the table. In addition, we have large cleaning equipment. Our plastic floating separation tank can process PP, PE, and PET plastic sheets. If you have other needs, please feel free to contact us and we will reply to you as soon as possible.

PET Bottle Flakes Washing Machine Price

To be honest, the price of PET chips washing machine is affected by many factors, such as distance, exchange rate, etc. In addition, many customers want to order PET chips washing machines to meet their needs. Therefore, if you want to know the specific price of the machine, please contact us. We will give you a detailed quotation for the machine according to your actual situation.

Do Plastic Flakes Melt in the Washing Machine?

The answer is No. Plastic can melt only at temperatures above 100 degrees. Therefore, plastic flakes will not melt in the PET flakes washing machine.

In Summary

In conclusion, we believe that the sinking tank is an important first step in the PET washing process. It has the potential to enhance the recycling of plastic bottles and reduce the loss of subsequent recycling machines. If you are seeking a solution for plastic bottle recycling washing that could be of benefit to you, we would be delighted to hear from you. Please don’t heistate to contact us by click here.