PET Flakes Friction Washer

| Model | SL-1000 |

| Capacity | 500-100kg/h |

| Length | 3000mm |

| Power | 7.5kw |

| Out Layer | 4mm |

| Blade Thickness | 6mm |

You can now ask our project managers for technical details

PET flakes friction washer is a machine for cleaning plastic sheets in the plastic bottle washing line. It is behind the plastic bottle hot water washing tank. This machine and the PET bottle flakes hot washing machine can work together to clean the plastic bottles with stains. Therefore, the PET flakes washer machine is an efficient cold water washer.

What is the working process of the PET flakes friction washer?

High speed friction washer as plastic cleaning equipment has their own unique functions and advantages. After the plastic sheet enters the silo, the high-speed rotating screw will fully rub the material with water. Under the action of high-speed rotating centrifugal force, the machine will separate the impurities (soil, sand, leaves, pulp) on the material surface. The dirty water will be washed with clean water. The water spray device and high-speed screw equipped with the PET flakes friction washer can clean the dirt on the plastic sheet.

What is the function of high speed friction washer?

The main function of the friction cleaner is to remove oil, glue, paper pulp, and other stains on the plastic bottle by using the friction force of high-speed rotation. The materials are mixed at high speed in the washer, and the friction between each PET sheet helps to remove dirt and debris. Then the filter screen inside the machine will discharge the dirt washed out. This allows the plastic bottle to be completely cleaned. In addition, the user can manually control the cleaning time of materials according to the pollution degree of materials. The PET flakes friction washer also has the advantages of a small floor area, simple operation, and high output.

Machine parameters

| Model | SL-1000 | SL-2000 |

| Capacity | 500-1000kg/h | 2000kg/h |

| Length | 3000mm | 3500mm |

| Power | 7.5kw | 15kw |

| Out Layer | 4mm | 4mm |

| Blade Thickness | 6mm | 6mm |

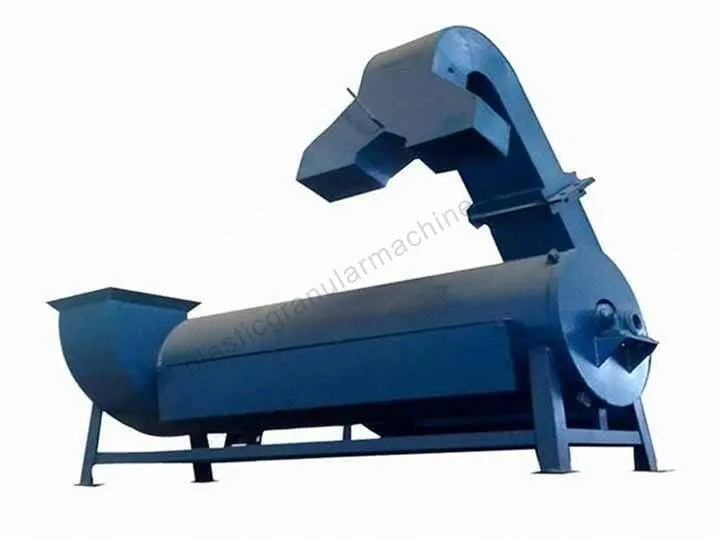

Structure of PET flakes friction washer

The body of this plastic bottle washing machine is composed of a foot stand, a motor, a host machine, a water inlet, a material inlet, a material outlet, etc. In addition, there is a fine screen filter at the bottom of the machine for filtering dirty water.

What are the applications of the machine?

In fact, our machines can handle most of the bottles on the market, such as Coke bottles, soda bottles, juice bottles, tea bottles, mineral water bottles, and other drinking water bottles.

Recycled pet flakes use

The recycled plastic sheets can generally be used for plastic packaging, fiber, glass fiber reinforced materials, modified plastics, and plastic woven bags. In this way, the PET bottle can be reused.

Summary

In a word, the PET flakes friction washer is an indispensable machine in the pet bottle washing plant and the plastic bottle recycling line. If you want to know more information about this machine, please feel free to contact us.