PET Bottle Washing Plant

| Capacity | 500-6000kg/h |

| Raw Materials | Water bottles, medicine bottles, beer bottles, bottle bricks, etc. |

| Final Products | Uniform PET flakes |

| Quanlity of Workers | At least 4 workers |

| Services | On-site installation and operation guides |

| Warranty | One year |

You can now ask our project managers for technical details

PET bottle washing line machinery includes bottle shredders, washing machines, and dryers, which can process your waste plastic bottles into clean flakes with a high economic benefit. Whatever capacity your factory has, we will provide you with 3D drawings and a proper PET recycling solution.

Key Features of PET Bottle Washing Line

- Adopting a three-stage washing method, the Efficient PET bottle washing recycling machines can thoroughly remove dirt, impurities, etc., ensuring the quality of the PET chips obtained and reducing the scrap rate.

- Strong power, no jamming, continuous and stable production.

- Made of high-quality stainless steel, the PET flakes washing line is durable, resistant to corrosion, and resistant to high temperatures.

- Modular customization is possible to meet your production needs better.

Raw Materials & end Product of PET Bottle Washing Line

Raw Materials

It is suitable for bulk plastic bottles and compressed PET bottle bricks. Our plastic bottle washing recycling plant is also capable of compressing and baling PET bottle bricks. Our equipment is equipped with an advanced unpacking system that can efficiently unpack bottle bricks.

Final Product

- Through professional cleaning processes, PET sheets achieve a high degree of cleanliness.

- After the drying process, its humidity is less than 1%. Humidity control is to ensure that the PET sheets do not get wet during subsequent processing and application and maintain stable physical properties.

- Application fields: Clean PET sheets can be widely used in various fields, such as the manufacturing of recycled PET bottles, fibers, films, sheets, injection molded products, etc.

PET Bottle Washing Recycling Line Machinery

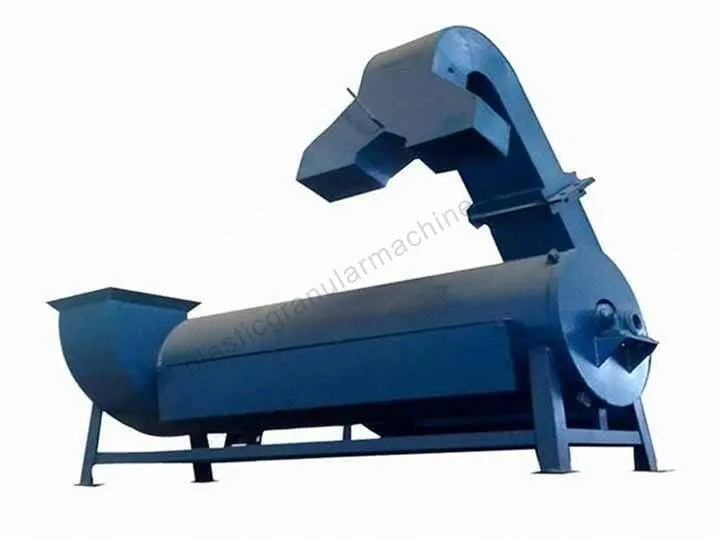

The main machines of the PET bottle washing line are plastic bottle crushers, washing machines, and dewatering machines.

Plastic crusher: Once the plastic bottles enter the plastic crusher, there are rotating blades which cut the bottles into small pieces or fragments. In a bottle crushing machine, a screen is provided to control the size of the final plastic pieces. By selecting screens with different apertures, it is possible to produce a chip size that meets specific requirements.

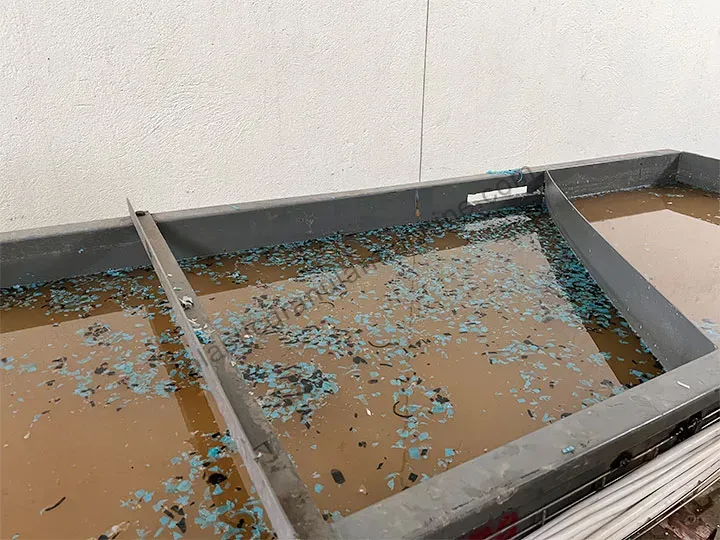

Plastic washing machines: PET flakes enter the floating washing tank. Through the different densities of plastics and debris, water acts as an intermediary to separate light impurities (such as labels, caps, etc.) from heavy impurities (such as stones, metals, etc.) in the tank. Light impurities float to the surface of the water while heavy impurities are deposited at the bottom of the pool.

In a friction washer, PET chips are passed over rotating friction rollers. These brushes or rollers exert friction on the bottle surface, removing dirt and residue from the bottle surface.

Hot water at 70-80 degrees Celsius in the hot wash tank heats the PET bottle flakes for cleaning. The addition of lye and high temperatures help remove more stubborn dirt and kill bacteria.

Dewatering machines: Plastic is subjected to a rotational, centrifugal process in a plastic dewatering machine. These forms of motion can help to shake moisture out of the plastic, making it drier.

Hot Washing or Cold Washing?

There are some factors that could influence the washing method and washing temperature.

Degree of Contamination

If the contamination on the PET plastic bottle is light, such as only some light sand or residual liquid on the plastic bottle, a cold wash may be all that is needed. However, if the PET bottle is contaminated with more serious contamination, such as grease, food residue, paint and other stubborn adhesions, a hot wash tank may be required to ensure better cleaning results through hot washing and clearing at higher temperatures.

Area of PET Application

The use of the PET bottle is also a consideration. For example, PET bottles used for food and beverage packaging may require higher washing standards to ensure that no harmful substances remain after recycling, a situation that requires consideration of how the plastic is washed.

Environmental Requirements

Hot washing may require more energy, while cold washing is more energy efficient. In the pursuit of a more environmentally friendly and sustainable production process, some producers may prefer to utilize cold washing technology.

Successful Cases of Plastic Bottle Flakes Washing Machines

Oman Plastic Bottle Recycling Project

Our plastic bottle washing machines and crushing machines have shipped to Oman this year. We are grateful for the customer’s trust.

Nigeria Plastic PET Bottle Washing Plant Installation

Nigerian customer purchased Efficient PET bottle recycling machines for their new recycling business. For the number of machines is large, we arranged for our technical staff to their plant, helping them to install the recycling plant.

Start your PET bottle washing plant now!

If you are interested in our PET bottle washing lines, or would like to learn more about our customized solutions, please feel free to contact us. Our professional team will wholeheartedly provide you with detailed consulting services and provide you with 3D design drawings to tailor a PET bottle washing plant solution that best suits your situation.