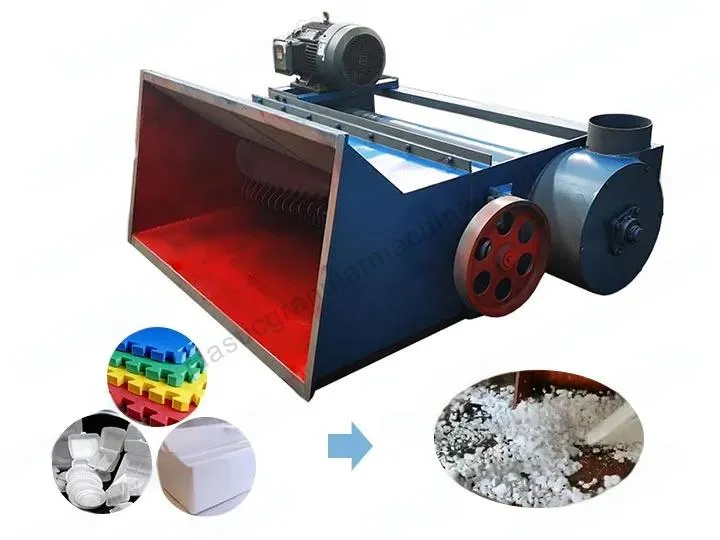

Hard Plastic Shredder | PP PE HDPE, etc. Hard Plastic Crushing Machine

| Model | SL-600, SL-800, SL-1000 |

| Power | 30, 45, 55KW |

| Capacity | 600~1200kg/h |

| Blades Material | 60 Si2Mn |

| Warranty | one year |

You can now ask our project managers for technical details

Hard plastic shredder, a crucial component served in plastic recycling lines for PP, PE, HDPE, LDPE, etc. It is specially designed to crush rigid plastics into smaller pieces for subsequent recycling processes, improving recycling efficiency.

Key Features of the Efficient Hard Plastic Shredder

- Various knives are available, including flower, flat, slicing, etc., made of high-quality stainless steel, and sharp and durable.

- High-quality stainless steel material, non-staining, non-sticking, easy to clean, adjustable spacing, and durable.

- 15-55kW of power, powerful burst, low failure rate, fast heat dissipation.

- Overload protection and power protection help to ensure safe and standardized production.

- Detachable screen design for easy cleaning.

- Provide a one-year warranty, on-site installation, and operation guides.

What are the Raw Materials and Final Products of Crushers?

Raw Materials

The Efficient hard plastic shredder has a wide application for crushing PP, PE, PVC, HDPE, ABS, PC, etc. It is typically used to process: Plastic, electronics, plastic containers, automotive parts, luggage, plastic kitchen utensils, water bottles, blue drums, etc.

Related blog: Efficient plastic pipe crushing program summary: for HDPE, PVC, etc.

Final Products

The plastic crusher produces uniform flakes of the required sizes, which are used in the subsequent pelletizing process.

Specifications of the Hard Plastic Shredder

| Model | SL-600 | SL-800 | SL-1000 |

| Power ( KW ) | 30 | 45 | 55 |

| Capacity ( kg/h ) | 600~800 | 800~1000 | 1000~1200 |

| Blades Material | 60 Si2Mn | 60 Si2Mn | 60 Si2Mn |

| Warranty | One-year | One-year | One-year |

- CE&ISO certification

The above are the parameters of some hot-selling shredders. They have a variety of applications for plastic recycling factories of all sizes. We also provide customized hard plastic shredding machines based on your production needs.

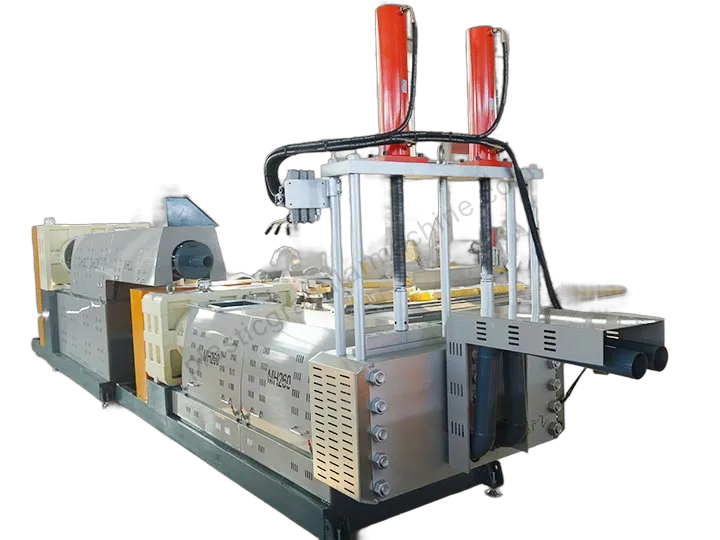

Plastic Shredder Structures

A plastic shredder consists of a feed inlet, crushing chamber, blades, screen, base stand, motor, pulley, and discharge port.

The blades attached to the rotor and rotating with it are known as rotor blades. On the other hand, the blades that are fixed to the crusher blade frame or housing are called stationary blades and they remain in place without rotating. Both the rotor blades and the stationary blades collaborate to effectively cut hard plastic into uniform fragments.

How Does A Rigid Plastic Crushing Machine Work?

Feeding

- First, plastic raw materials are manually fed or conveyed into the feeding port of the crusher by a conveyor belt, and then they are processed in the crushing chamber.

- Equipped with long cylindrical forms, broad rectangular configurations, etc. feed inlets, our hard plastic shredders are suitable for various plastic products.

Crushing

- The rotating blades of the crusher’s rotor rotate at high speed, forming a shearing effect with the fixed blades. Together, they crush the plastic raw materials efficiently.

- The Efficient crusher features thick blades that can crush strongly and efficiently without getting stuck or clogged.

Screening

- Crushed plastics will be screened by the screen. The required sizes of plastic flakes can pass through the screen, while larger fragments remain in the chamber for further crushing.

- The mesh size can be adjusted based on your production needs. It is recommended to use a mesh size of 16mm or larger when processing large materials for smooth operation.

Discharging

The plastic fragments that pass through the screen are subject to gravity and fall directly to the bottom, where they are discharged through the outlet.

Operation Video

Below is a feedback video from an Oman customer, which demonstrates the process of transforming HDPE plastic materials into flakes.

What Does Efficient Do About Shipment?

- The machine will take about 20-25 days to be delivered if there is no stock available.

- Before shipment, we commonly send the test run demo to our customer, ensuring there are no problems.

- Ship plastic shredders through international logistics.

- If there are any defective parts, they can be re-shipped.

In short, the services we offer are comprehensive, ensuring your peace of mind regarding potential accidents.

Efficient Plastic Crushers for sale

The Efficient PP crusher can be customized to meet the needs of all sizes of rigid plastic recycling lines and is suitable for all types of hard plastic recycling or manufacturing factories. If you’re interested, don’t hesitate to contact us. We are delighted to provide on-site inspection services and accompany you on tours, offering detailed explanations of the machines. Additionally, we would be happy to share suggestions for optimizing your factory’s layout. We look forward to your news!