Rigid Plastic Recycling Line for PP PE PVC HDPE Regrinding

| Capacity | 100~500kg/h |

| Raw Materials | Rigid PP, PE, PVC, HDPE, ABS, etc. |

| Final Products | Uniform plastic granules |

| Warranty | One year |

| Services | On-site installation and operation guides |

You can now ask our project managers for technical details

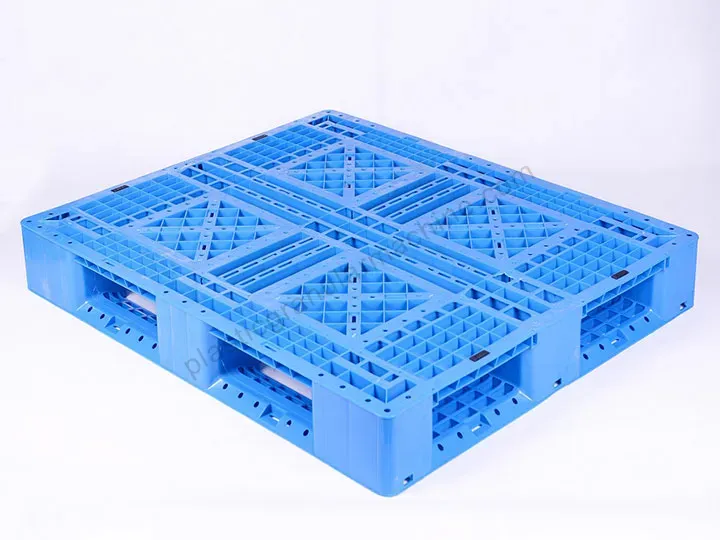

Are you seeking the best solution to recycle pallets, pipes, oil cans, extrusion head materials, etc.? The hard plastic recycling line provides a complete and efficient method of grinding PP, PE, PVC, HDPE, etc. into high-value granules.

Key Features of the Efficient Hard Plastic Recycling Line

- Wide range of applications: Easily process various hard plastics and suitable for all sizes of factories.

- 100~500kg/h capacity and powerful engines for efficient and continuous production.

- Various customizable machines are available for selection and combination, with flexible configuration.

- It is equipped with an intelligent temperature control system for precise control of granulation temperature.

- The produced granules have high quality, smooth and even surface, and good physical properties.

What Types of Plastic Processing Are Efficient Recycling Machines Suitable for?

Raw Materials

The hard plastic recycling line is specially designed to transform PP, PE, PVC, HDPE, ABS, etc. plastics with high strength and rigidity into reusable granules. These materials are typically can be collected from the below fields:

- Daily necessities: Toys, furniture, food containers, etc.

- Construction: Pipes, window frames, etc.

- Automotive industry: Bumpers and other parts

- Electronic products: Insulating cases, connectors, etc.

- Packaging Industry: Rigid plastic buckets, cans, etc.

Final Products

These hard plastics are finally transformed into uniform pellets, which can be used to manufacture new plastic products.

Suitable Factories

The Efficient hard plastic recycling line is highly versatile and can be customized to meet the needs of factories of all sizes. This makes it suitable for both small and large plastic recyclers looking to recycle post-consumer materials, as well as manufacturers aiming to reclaim post-industrial plastics.

How Does the Recycling Process Work?

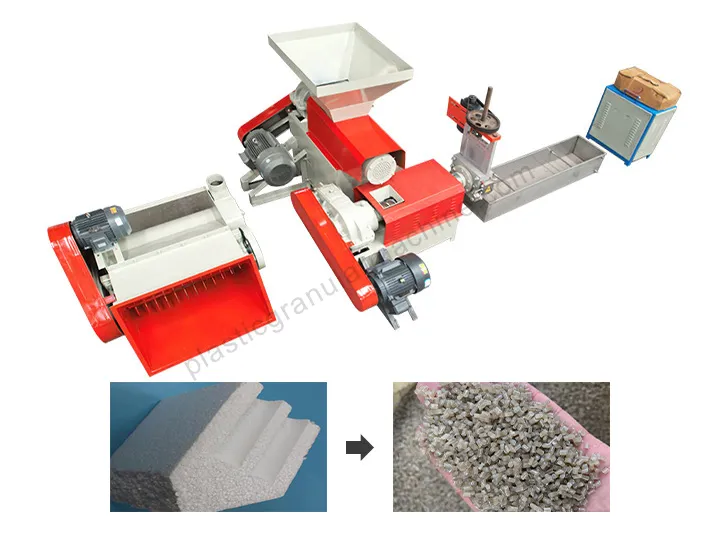

Step1: Crushing

Firstly, rigid plastics are fed into a plastic shredder to be crushed into smaller flakes, which are more convenient to wash and pelletize. By raw materials classification, the sizes of the obtained flakes are different and can be adjusted. They are typically about 10~20mm for the subsequent processes.

The plastic shredder utilizes the shearing force of the rotating blade and stationary blade to crush large and hard materials efficiently without jamming.

- Material: 60Si2Mn

- Capacity: 600~1200kg/h

- Raw Materials: rigid plastics

- Final Products: uniform flakes

Step2: Washing

Plastics intended for recycling often have dirt and other impurities on their surfaces, which must be washed off in a washing tank to ensure the purity and cleanliness of the recycled materials.

The plastic washing tank is typically about 10~30m long and can be customized based on your production needs. It uses a water circulation system, which is highly efficient and energy-saving.

- Power: 3KW

- Length:10~30m

- Function: Wash plastics and remove impurities.

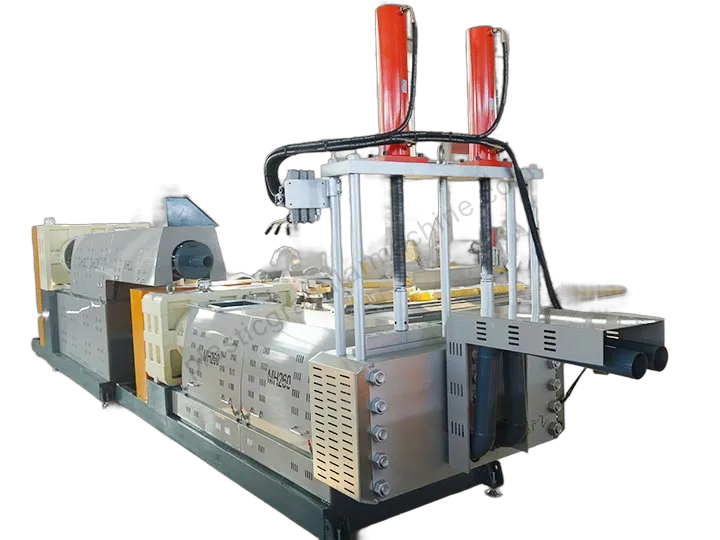

Step3: Pellerizing

The plastic pelletizing machine is an essential piece of equipment that converts plastic into granules. The entire process involves heating, extruding, cooling, and cutting.

- Using high-temperature screw melting technology, plastics are heated until molten and then extruded into long strips by the die head.

- These dense strips pass through a cooling tank to solidify and enhance their surface smoothness.

- Finally, a plastic pellet-cutting machine cuts the long strips into uniform granules.

- Power: 30~75KW

- Output: 180~380kg/h

- Material: High-quality stainless steel

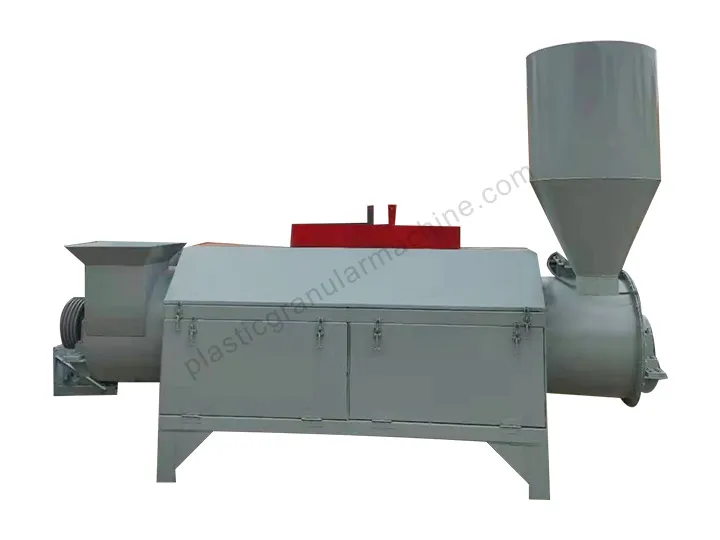

Step4: Drying

A plastic dryer is specially used in plastic recycling lines to dewater plastic after cleaning or pelletizing. The dewatering rate is more than 97%.

- Power: 7.5~15 KW

- Dewatering Rate: more than 97%

- Material: High-quality stainless steel

- We provide matching suggestions and factory designs based on your production needs.

- Welcome to visit our factory for inspection!

- Delivery time is about 20-25 days after placing an order.

- Ship through international logistics.

- We provide a one-year warranty, on-site installation, and adjustment services.

Efficient has more than ten years of experience, large production workshops, and professional teams. I hope we can cooperate to improve your production efficiency!

Sharing Successful Cases

In the past several years, shuliy has successfully exported many plastic recycling machines all over the world. Here are some recent cases of hard plastic recycling lines. If you’d like to get more information, please feel free to contact us.

- Plastic Pellet Making Machine Exported to Germany

- PVC granulator machine shipped to Oman successfully

- Continued cooperation: plastic recycling pellet machine sent to Mozambique

Customer Feedback Video

The Efficient hard plastic recycling line has received widespread praise due to its numerous advantages. This is a feedback video from our Oman customer.

Look Forward to Your News

In short, the Efficient hard plastic recycling line features high efficiency, high quality, and low energy consumption. Besides, we provide comprehensive services to satisfy all of your production needs. If you’re interested, please feel free to contact us.