Force Feeder For Extruder

| Model | SK-600 |

| Power | 2.2KW |

| Size | 600*600*1200mm |

| Application | PP, PE, LDPE, HDPE films, LLDPE, EPS, EPE, etc. |

| Warranty | One year |

| Services | Technical support and on-site installation. |

You can now ask our project managers for technical details

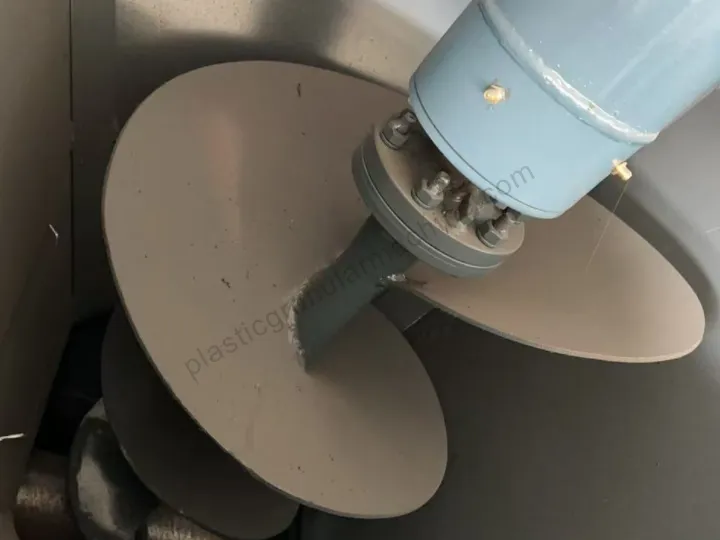

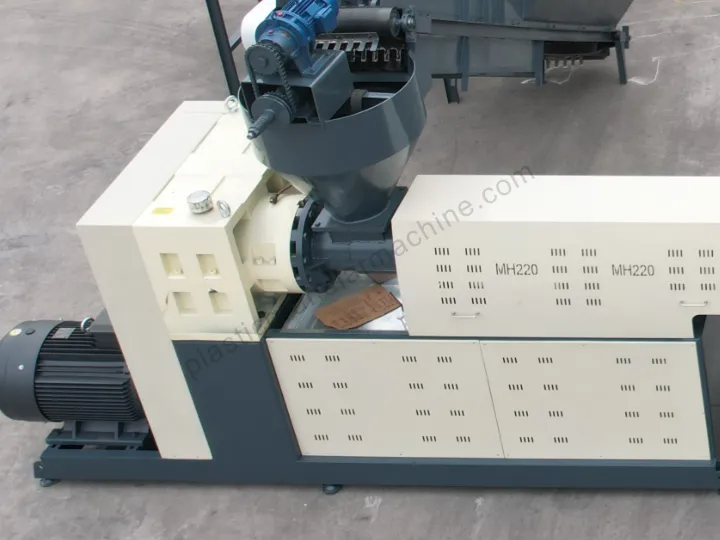

The EFFICIENT forced feeder is a specialized feeding device designed for the pelletizing of soft plastic films, such as PP, PE, LDPE, etc. This force feeder for extruder ensures a uniform, stable, and smooth supply of waste plastic materials to the plastic granulator by utilizing an advanced screw conveyor feeding system. This reliable feeding mechanism provides a strong foundation for effective plastic pelletizing.

Why We Need A Forced Feeder?

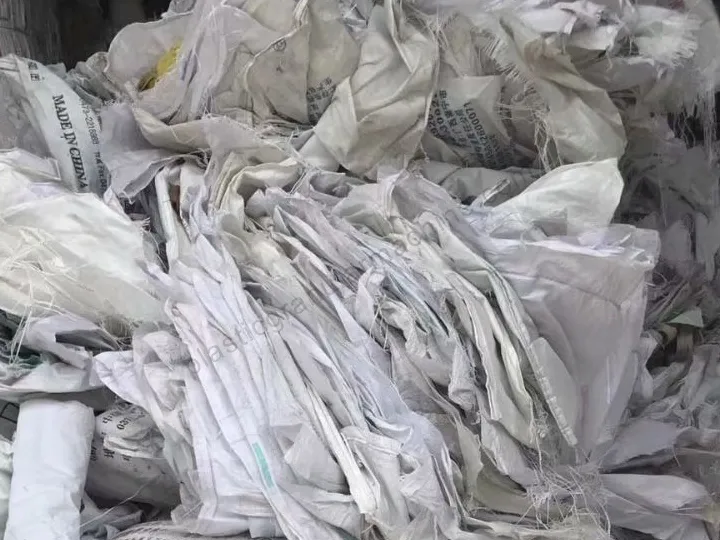

Plastic films, such as PP stretch films, PE bags, etc. are characterized by their large volume and low density. As a result, traditional feeding methods used during pelletizing can lead to clogging and winding issues. These problems negatively impact both the efficiency and quantity of plastic recycling.

By utilizing the mechanical force of the extruder’s screw in the force feeder, you can achieve continuous and stable feeding, which ensures the stability and uniformity of plastic pelletizing.

Advantages of Our Force Feeder Hopper

Improve plastic pelletizing effect:

- Screw forced feeding effectively improves the feeding efficiency of plastic film.

- Uniform feeding, to prevent fluctuations in the amount of material in the extruder, to ensure the stability of the extrusion process and product quality.

- Compression of plastic to improve the density and thus reduce air entrainment, improving the subsequent melting pelletizing effect.

Low operating costs

- Enhanced energy efficiency: Our high-efficiency motor and improved spiral blades deliver strong performance with reduced resistance and lower energy consumption. The motor speed is adjustable to match production needs, ensuring precise feeding and minimal energy waste.

- Long service life: adopt high-quality stainless steel material, wear-resistant and anti-oxidation corrosion, low maintenance cost.

- Reduce manpower: Perfectly connect the conveyor and pelletizing system, realize fully automatic and precise feeding, reduce manpower consumption.

Simple operation and flexible adjustment

- Automated design, easy to grasp the operation

- Flexible adjustment of screw speed, feed pressure, and other parameters to ensure the best feeding and extrusion effect.

Wide Application

This force feeder for extruder can be applied to many kinds of plastics, such as PP, PE, LDPE, HDPE film, EPS foam, EPE foam, etc. The machine can be used in the recycling of various plastics.

For different plastic raw materials, you can flexibly adjust the settings of each parameter to promote the effect of plastic recycling.

How Does The Force Feeder For Extruder Work?

- The pre-treated plastic raw material enters the feeder hopper through the automatic feeding device.

- The screw of the feeder compresses the plastic by rotation and transports it to the screw of the extruder

- The force feeder for extruder provides the pelletizer with an even and steady raw material supply, ensuring subsequent high-quality melt pelletizing.

Technical Data of The Feeding Machine

| Model | SL-600 |

| Power | 2.2KW |

| Size | 600*600*1200mm |

| Application | PP, PE, LDPE, HDPE films, LLDPE, EPS, EPE, etc. |

| Function | Reliable supply of raw materials for plastic granulators. |

Operational Effects of Force Feeders in Extrusion

The force feeder is usually used in conjunction with the plastic pelletizer, which has helped customers in many countries, such as Nigeria, Ethiopia, Saudi Arabia, etc., to realize efficient and high-quality plastic pelletizing production and has been widely praised.

The following are some successful export cases. For more information, please contact us for the best customized plastic pelletizing solutions!

Our Service

- – Customized granulation solutions

- – Repeated debugging to ensure no error

- – Smooth and speedy international logistics

- – On-site installation and technical guidance

- – After-sales timely response, one year free warranty

- – Lifetime parts supply

Conclusion

The force feeder for extruder is an important machine to ensure the stability and efficiency of the plastic granulation process, providing uniform and continuous raw material delivery and improving the efficiency and quality of plastic granulation. If you are looking for a suitable plastic pelletizing feeding solution, welcome to contact us!