EPS Pelletizing Machine | Foam Granulator

| Type | 220/270/220/270/320/350 |

| Capacity (KG/H) | 150-375 |

| Main Motor (KW) | 15/18.5/15/18.5/18.5/22 |

| Reducer | Double/Single |

| Warranty | One year |

You can now ask our project managers for technical details

The EPS pelletizing machine is a machine that transforms waste EPS foam into recyclable EPS pellets. EPS pellets can be used in industry, agriculture, and construction industries. At the same time, the EPS pelletizing machine is also the most important piece of equipment in the EPS foam recycling line. Therefore, this styrofoam granulator machine plays a key role in EPS foam recycling.

Key Features of Efficient EPS Pelletizers

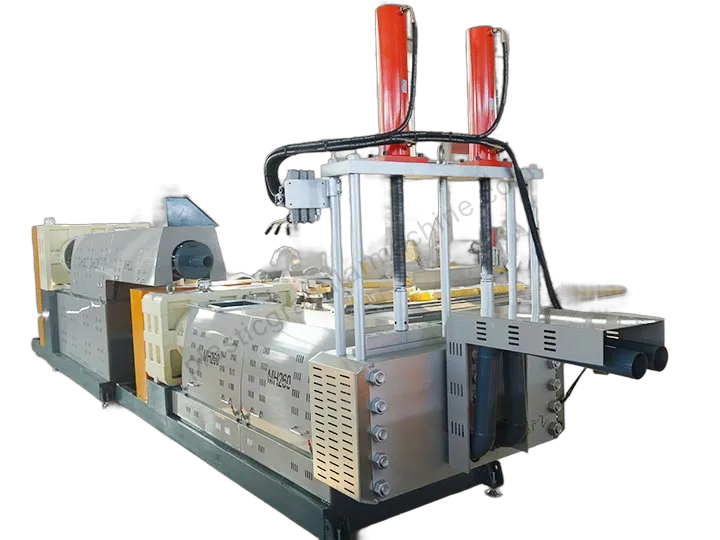

- It can automatically and continuously produce, ensuring the stability of the granulation process and the quality of the EPS pellets.

- Made of high-quality stainless steel, it is durable, resistant to high temperature, resistant to corrosion, and is not easy to deform.

- The styrofoam granulation process is visualized and equipped with an intelligent control cabinet, making it easy to follow the granulation process and strictly control temperature, time, etc. during the plastic foam pelletizing process.

- It takes up little space, consumes little electricity, and produces high-quality products.

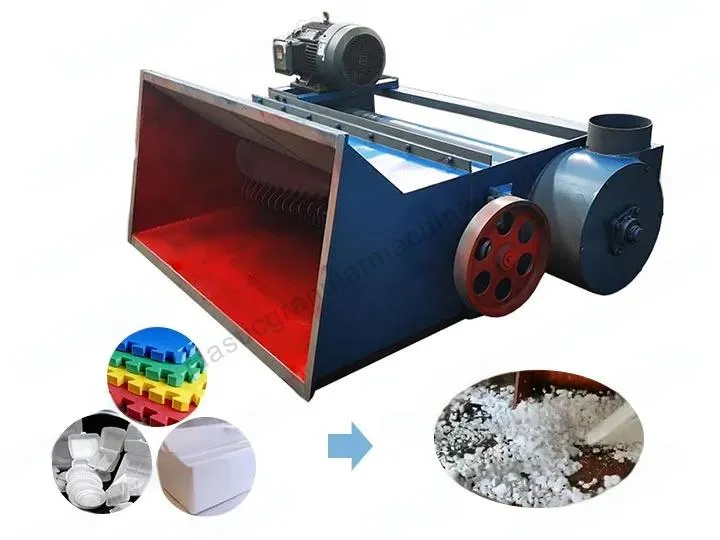

What Are The Raw Materials and Final Products of The EPS Foam Grinder?

Raw Materials

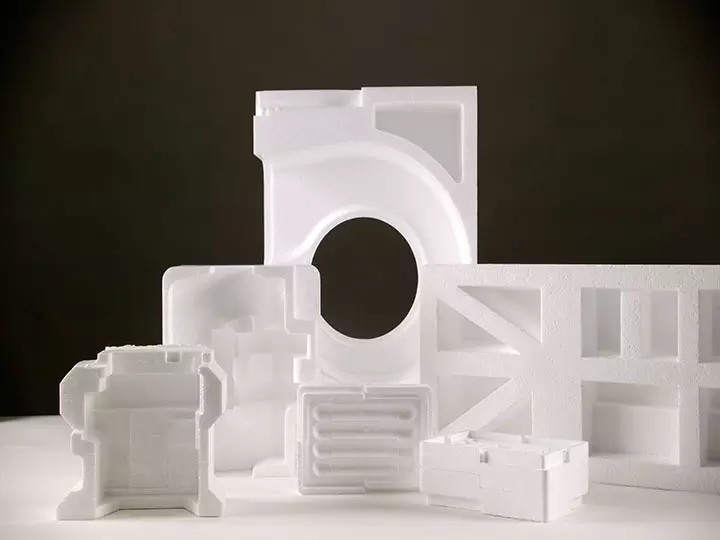

This EPS granulator can be used to process various types of waste foam, such as insulation foam, extruded polystyrene, waste foam boxes, foam packaging with additives, foam dinnerware, and EPE (expanded polyethylene).

End Products

The EPS pelletizing machine processes waste plastic styrofoam into uniform recycled pellets, which can be used to manufacture new plastic products in many fields, such as packaging, construction, etc.

Besides, by adding different pigments, chemical agents, etc. during the granulation process, EPS granules can ultimately have different colors and properties for different production needs.

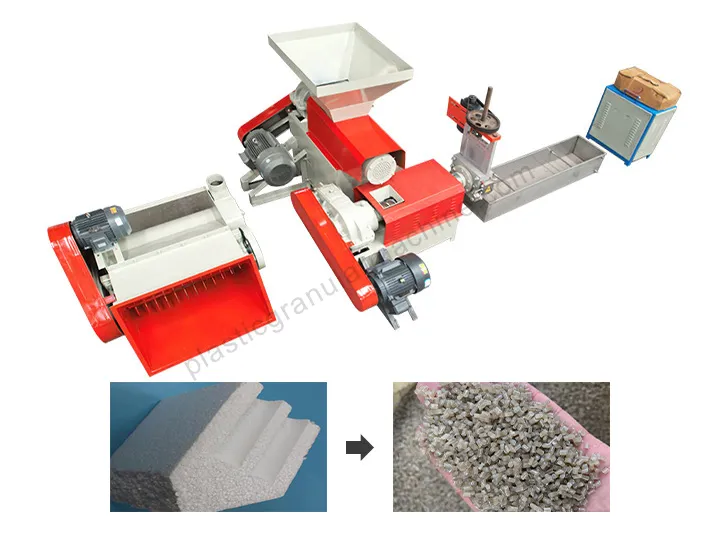

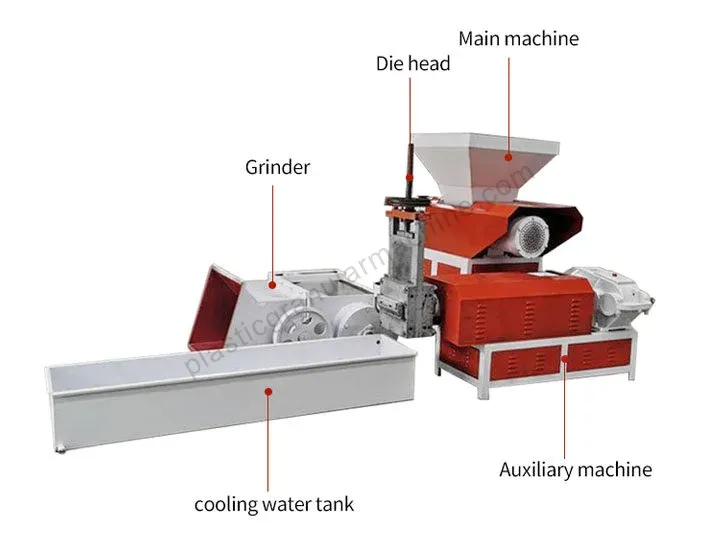

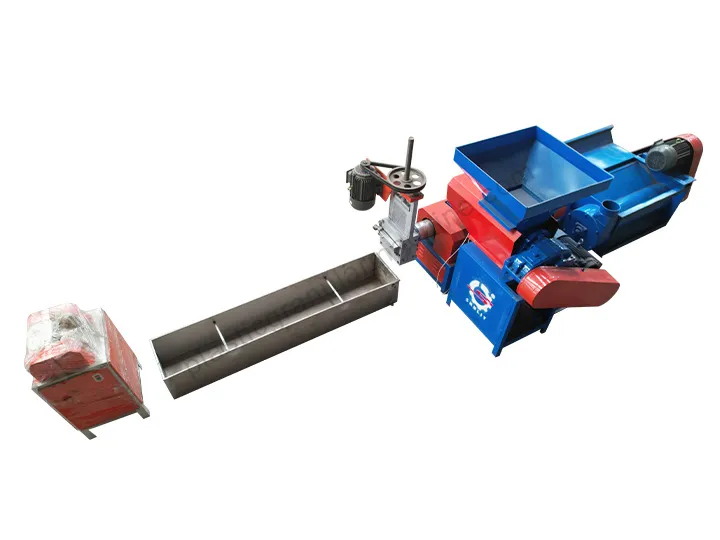

Structure of the EPS Granulator

The whole EPS foam granulation system includes the main machine, auxiliary machine, die head, grinder, and cooling pool.

How Does an EPS Pelletizing Machine Work?

EPS foam granulator processes waste EPS foam through physical or chemical methods such as pretreatment, melting, granulation, and granulation. Firstly, the EPS granulation host melts EPS plastic and extrudes the auxiliary machine. Then the long strip material is extruded from the granulation auxiliary die into the cooling pool. Finally, the pellets cutting machine cuts the EPS strip into EPS pellets of uniform size. After this series of operations, we can get EPS foam pellets. This is the whole EPS foam granulation system.

Machine Parameters

| Type | Capacity (KG/H) | Main Motor (KW) |

| 220 (Double Reducer) | 150-175 | 15 |

| 270 (Double Reducer) | 220-225 | 185 |

| 220 (Single Reducer) | 150-175 | 15 |

| 270 (Single Reducer) | 220-225 | 18.5 |

| 320 (Double Reducer) | 275-300 | 18.5 |

| 350 (Double Reducer) | 325-375 | 22 |

The above is basic data of some hot-selling EPS pelletizing machines. We provide various models and styles to meet different styrofoam pelletizing needs. We can also provide customized granulators. For specific information, please consult our marketing manager.

Why is the EPS pelletizing machine popular?

On the one hand, life is full of all kinds of EPS foam products. In addition, EPS foam is mainly used in foam snack boxes, foam fresh-keeping boxes, and food insulation materials. At the same time, EPS is also the packaging foam of TV sets, air conditioners, refrigerators, and other furniture. These EPS products will cause great environmental pollution if they are not recycled. On the other hand, environmental protection has become a fashion. Various countries are also advocating environmental protection. Therefore, EPS pelletizers can make a lot of profits.

Application of EPS foam pellets

- In daily life, recycled pellets can make all kinds of EPS foam bags, barrels, basins, toys, furniture, stationery, and other household appliances.

- Clothing. We can use EPS plastic pellets to make clothes, ties, buttons, and zippers.

- Building materials. The derivative of EPS foam pellets, and plastic wood profiles, produce various building components, EPS foam doors, and windows, etc.

- Industrial supplies. Pellets can make pipes, containers, pumps, valves, etc. What’s more, it can be used in chemical production sites to solve corrosion and wear.

- Agricultural supplies. In addition, foam regenerated pellets can be used to make agricultural films, pumping pipes, agricultural machinery, fertilizer bags, cement bags, etc.

- In addition, recycled pellets made by EPS foam pelletizing machine are also widely used in the electrical industry and telecommunications industries.

The styrofoam granulator is often used in conjunction with an EPS crusher, etc., to jointly promote the production of high-quality recycled EPS pellets. Finally, if you need plastic recycling equipment, please feel free to contact us. In addition, we also have a plastic film granulator for sale.

Efficient EPS Pelletizing Machine Exported to Canada

Recently, our entire styrofoam recycling line, including an EPS granulator, was successfully exported to Vancouver to help a Vancouver foam recycling company solve the problem of inadequate recycling equipment. As an experienced plastic recycling machinery supplier, we are pleased to contribute to the recycling and utilization of plastics.

So, if you’re struggling with plastic recycling, please don’t hesitate to contact us!

Read: How We Boost Styrofoam Recycling Vancouver BC?

Our services

- Custom machines are available with about 20-day lead time.

- Welcome to our factory to see our EPS pelletizing machines!

- A test video will be sent before shipment to confirm there are no errors.

- We provide technical support and a one-year warranty.

In summary, our styrofoam grinder machine features high quality, high efficiency, etc. If you’re seeking for great solution to grinding your waste foam raw materials, we’ll be your best partner. Don’t hesitate to contact us!