EPS Hot Melting Recycling Machine | EPS Foam Melting Machine

| Model | SL-220.SL-880, SL-1000 |

| Power | 15~22KW |

| Raw Materials | XPS, EPS, styrofoams, etc. |

| Final Products | Dense Ingots |

| Warranty | One year |

You can now ask our project managers for technical details

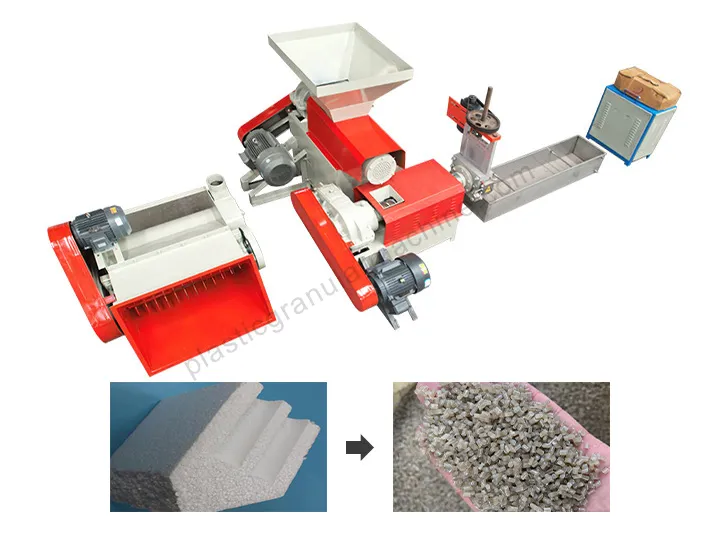

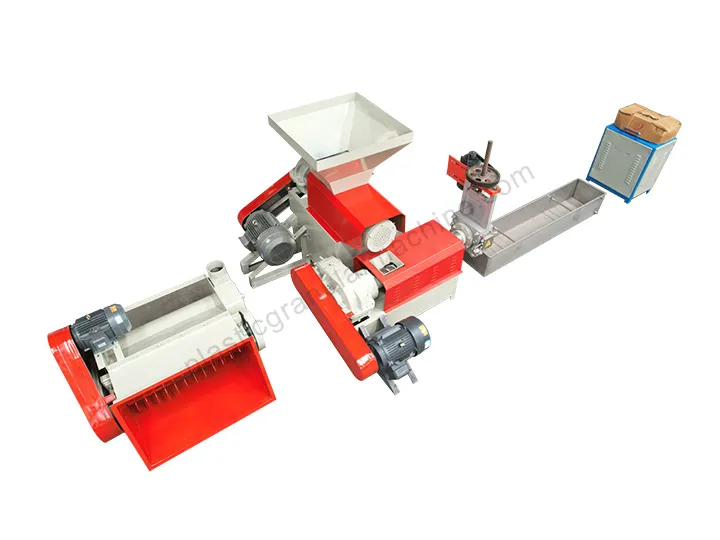

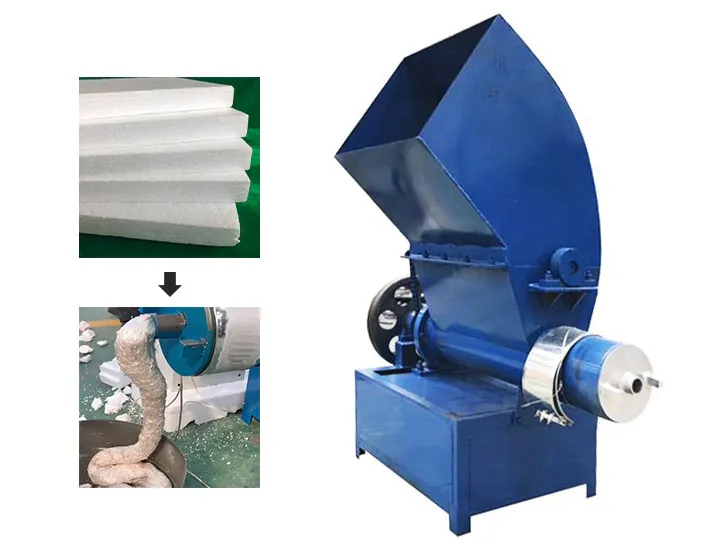

The EPS hot melting recycling machine can compress and melt the block EPS foam into a long foam strip with a small footprint. The melted styrofoam can be used to make other plastic products.

The EPS hot melting recycling machine, also called the EPS foam melting machine, is an important piece of equipment in the EPS recycling machine and plays an important role in the EPS recycling process. Many people do not know that foam can be melted and that EPS melting temperature is 150 degrees.

Why Use the EPS Hot Melting Recycling Machine?

As countries pay more attention to environmental protection, the waste plastic recycling industry has been developing rapidly. Besides the common plastic film and plastic bottles, more and more people are engaged in expanded polystyrene recycling. EPS foam is widely used in the packaging industry, but it is bulky and difficult to transport.

To make styrofoam easy to transport, Efficient Machinery has developed a new machine that can quickly melt and compact the used eps foam. The melted EPS foam is easy to transport and store. Also, the melted foam can go directly to the EPS foam grinding system in the EPS recycling process line.

Advantages of the EPS Hot Melting Machine

- The EPS hot melting recycling machine has the features of simple operation, small footprint, and convenient transportation of finished products.

- The automatic temperature control function can avoid abnormalities in the working process in order to achieve the expected melting effect.

- The machine power is between 18.5-22.5kw. With energy-saving and power-saving features.

- A variety of different output EPS hot melting machine for sale (100 kg per hour to 250 kg per hour). Customers can choose the right machine according to their needs.

- The eps machine will not change the physical properties of EPS foam, which is conducive to further recycling.

- The machine is made of high-quality material, which has a long service life and wears resistance

EPS Foam Melting Machine Video

Application Scope of the EPS Foam Melting Machine

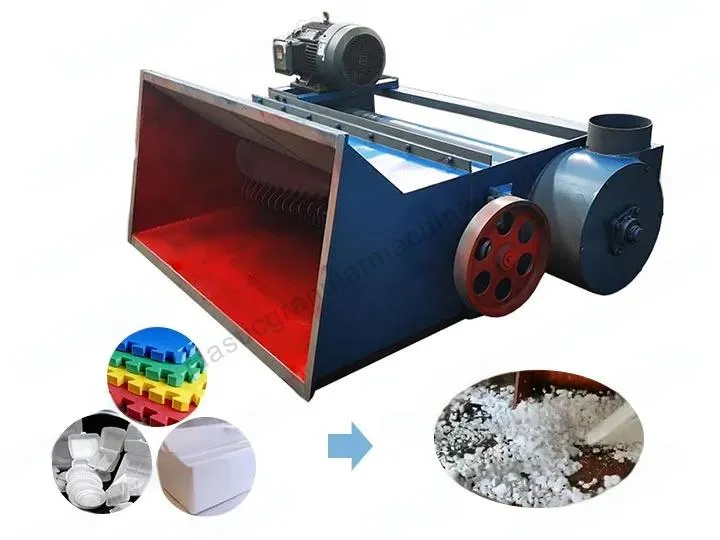

This EPS hot melting recycling machine can melt and lump many kinds of foam materials such as EPS, EPP, EPE, and EVA at high temperatures. Common foam materials are fast food boxes, packaging boxes, etc. So the machine is suitable for various plastic recycling plants.

It is usually used with a foam crusher to pre-treat the foam before granulation. EPS hot melting recycling machines are offered in various models to meet the production needs of different foam recycling lines.

What Is the Working Principle of the Machine?

The foam hot melt machine mainly adopts the structure of a draw plate, and the heat from the heating plate is transmitted to the fused surface of the upper and lower plastic by the method of electric heating.

Then it makes its surface melt, and then fuses and solidifies the molten surface of the upper and lower heating pieces, and then combines them into one.

The whole body of the machine is in the form of a frame, mainly composed of three plates: the upper template, the lower template, and the hot template.

The eps hot melting recycling machine mainly relies on pneumatic control. When welding, the workpiece is placed in the two-cavity molds and the heating plate is placed between the foam. When the heating plate temperature rises, the EPS foam starts to melt.

Technical Data of the EPS Hot Melting Recycling Machine

| Type | Outside Dimensions (mm) | Feed Port Size (mm) | Inlet Power (kW) | Capacity (kg/h) |

| SL-220 | 1500*800*1450 | 450*600 | 15 | 100-150 |

| SL-880 | 1580*1300*850 | 800*600 | 18.5 | 150-200 |

| SL-1000 | 1900*1580*900 | 1000*700 | 22 | 200-250 |

These are three of Efficient’s best-selling EPS recycling machines. In addition to these three models, we also have a variety of EPS melting machines for sale. In addition, we also provide customized service. If you need this machine, please feel free to contact us.

Something About Shippment

- The lead time for custom machines is approximately 20 days.

- Regularly report production progress and send you the test machine videos.

- Ship through international logistics.

- We can provide technical support and on-site installation services after the machines arrive.

- A one-year warranty is provided.

So, What are you waiting for? Consult now and enjoy the discounted price. If you’re interested, please don’t hesitate to contact us for these reliable recycling machines.