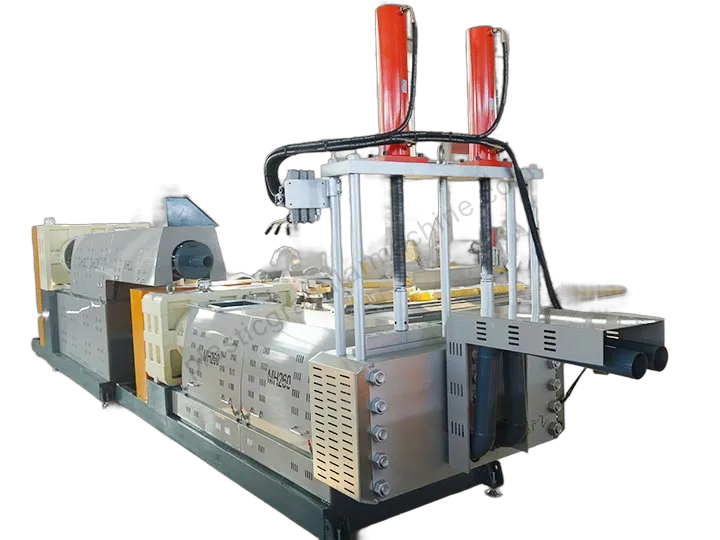

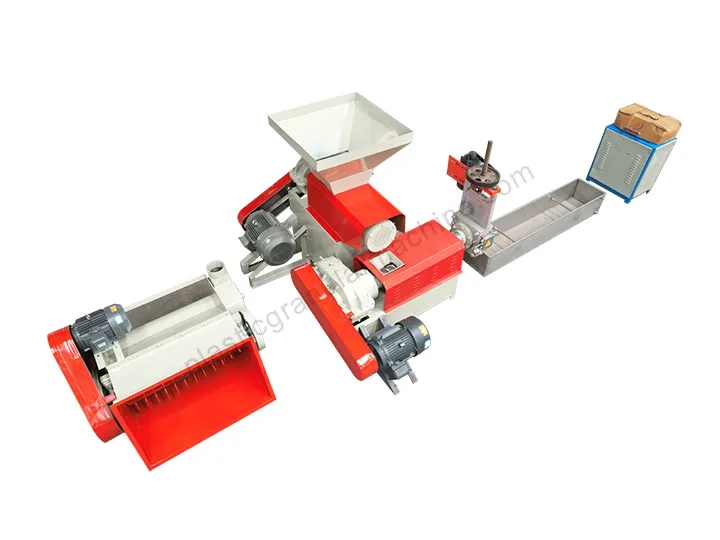

EPEプラスチックフォーム造粒機

| モデル | SL-160 |

| 原材料 | EPEフォーム、EVA、PEフィルムなど |

| 最終製品 | 必要なサイズの顆粒 |

| 容量 | 100~250kg/h |

| 力 | 30KW |

| 供給入口サイズ | 780mm×780mm |

| 保証 | 1年 |

| テクニカルサポート | 操作ガイド、現場での設置など。 |

技術的な詳細についてプロジェクト マネージャーに問い合わせることができるようになりました

EPEプラスチックフォーム造粒機は、EPEで作られたフォームを顆粒に加工するために特別に使用されます。最終的なプラスチック顆粒は、サイズが整っていて、色が均一であり、市場から良い評価を受けています。

EPEフォーム押出機の利点

- 幅広い応用範囲: カスタマイズされた EPE フォーム造粒機は、さまざまな規模の EPE ペレット化生産に効果的に対応できます。

- 操作が簡単: インテリジェントキャビネットを装備しており、生産の進行状況をリアルタイムで制御し、停止した場合は停止できます。

- 高い経済効率: 完成した粒子の品質が高く、経済的価値が高く、ペレタイザーのメンテナンスコストが低い。

EPE 押出機の利点はそれだけではありません。その秘密を一緒に探っていきましょう。

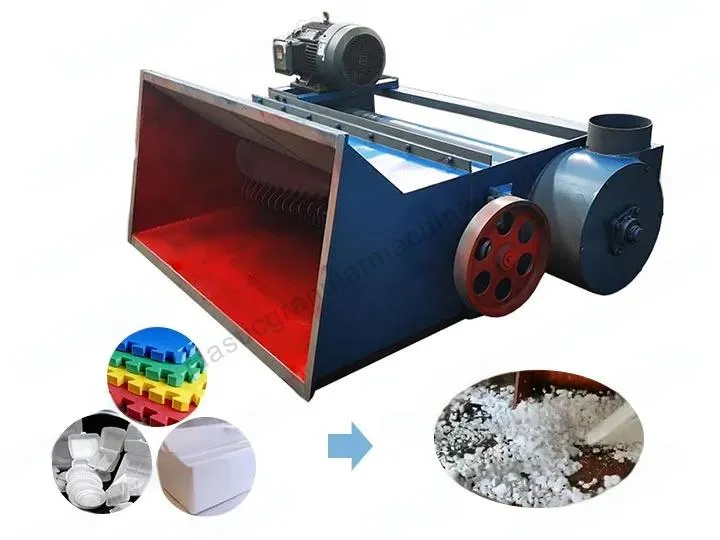

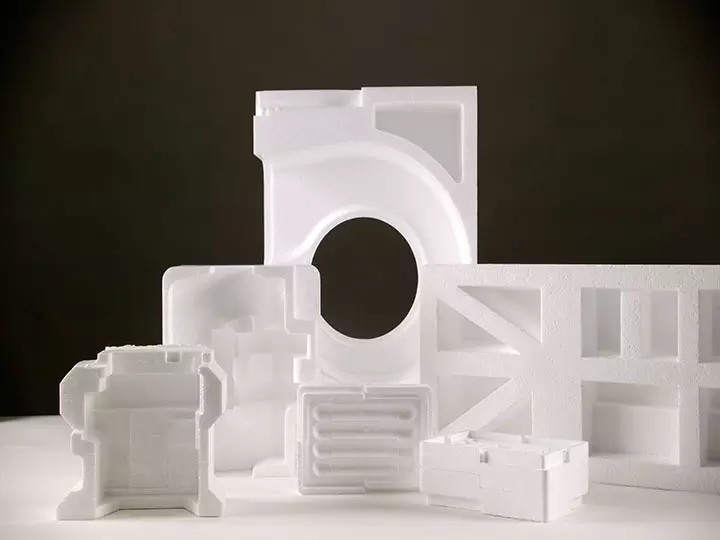

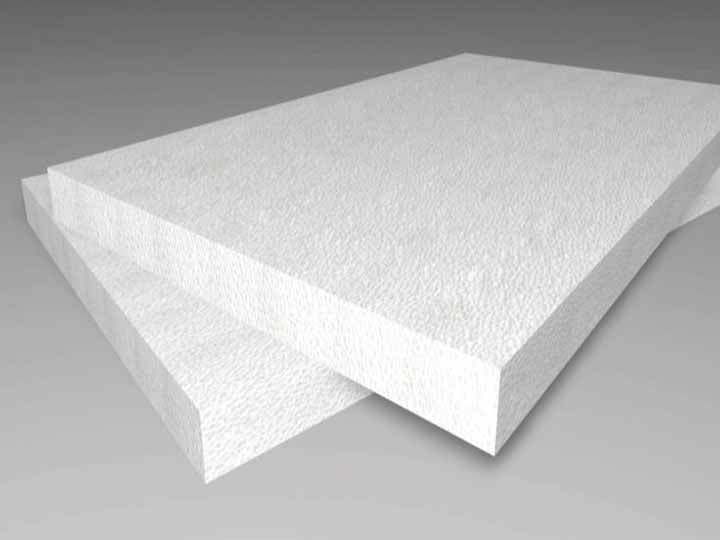

発泡プラスチック造粒機の原料

- 包装材料: EPE フォームは、特に電子製品、ガラス製品、セラミックなどの壊れやすい品物の包装に広く使用されています。

- 断熱材: EPE フォームはその断熱特性により、屋根、壁、その他の部品の断熱材として建設およびエンジニアリングで使用できます。

- 包装充填材: 箱や小包の商品に充填し、輸送中の損傷から商品を保護するための小包および充填材として使用されます。

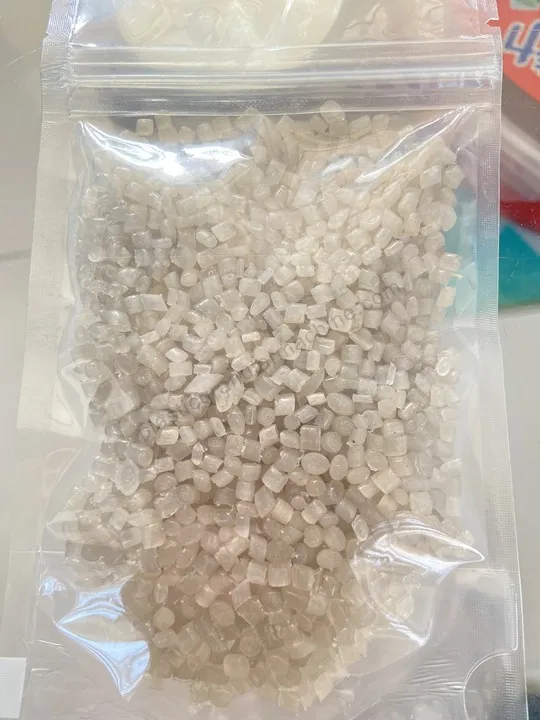

EPEプラスチック発泡造粒機の最終製品

当社の発泡プラスチック造粒機は、厳しい生産環境下でも高品質なプラスチックペレットを安定して製造できます。最終製品は新しいプラスチック製品の製造に使用でき、高い経済的価値があります。

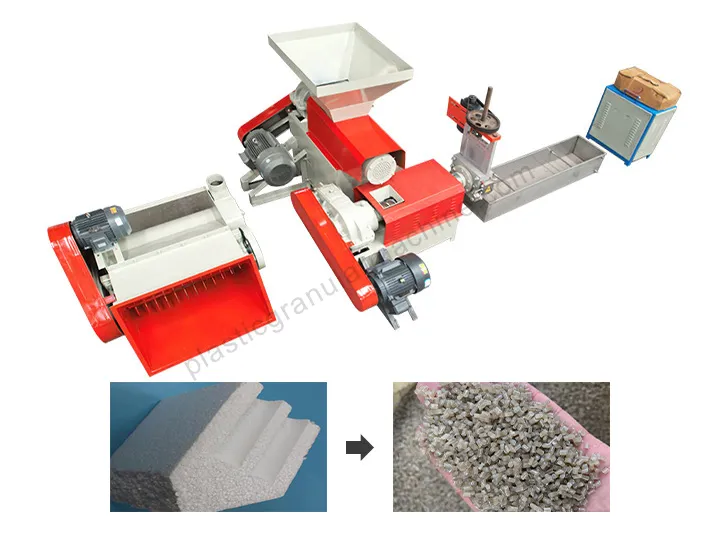

EPE造粒機の動作原理

粉砕: フォームが EPE 造粒機に入ると、まず粉砕システムを通過します。このステップは、後の処理のために大きな発泡材料を小さな塊に分割するように設計されています。

加熱と溶融: 粉砕されたフォームブロックは加熱システムを通過し、流体状態に溶融されます。このステップは、フォーム材料の物理的特性を変化させ、加工を容易にするのに役立ちます。

押出: 部分的に溶融したフォーム材料が押出システムに供給され、最終的にダイによってストリップに押し出されます。

冷却: プラスチック ストリップは冷却タンクを通過して温度を下げ、プラスチックの安定性と硬化を確保します。

切断: 冷却されたプラスチック ストリップはペレタイザーを通過し、そこで必要な長さのペレットに切断されます。

発泡プラスチック造粒機の動作ビデオ

このビデオでは、EPE プラスチック発泡造粒機が完全な状態でどのように機能するかを示します。 発泡スチロールリサイクルライン。かさばる廃棄発泡体を高品質の再生ペレットに変える発泡スチロールペレタイザーが大活躍!

要約すれば

エペのリサイクルについてご質問や発泡ペレット製造機が必要な場合はお気軽にお問い合わせください。当社の発泡ペレット化機は幅広い応用範囲と大容量により、あらゆる生産規模に適しています。特別なニーズがある場合は、カスタマイズされた機械も提供できます。