HDPE顆粒製造機 |プラスチックペレット化機

| ブランド | 効率的な機械 |

| 原材料 | PP、PE、PVC、HDPE、ABSなど |

| 最終製品 | 必要なサイズのプラスチック顆粒 |

| 容量 | 180-380kg/h、カスタマイズ可能 |

| 力 | 30-75KW |

| 保証 | 1年 |

| サービス | 技術サポート、オンサイト設置など |

技術的な詳細についてプロジェクト マネージャーに問い合わせることができるようになりました

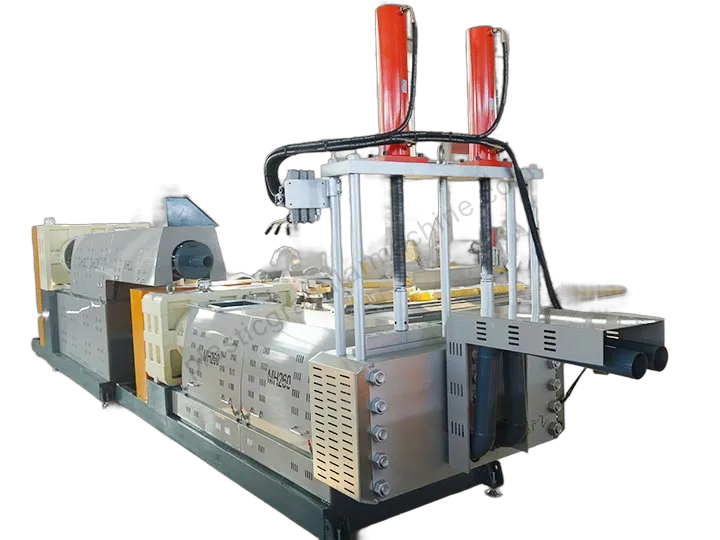

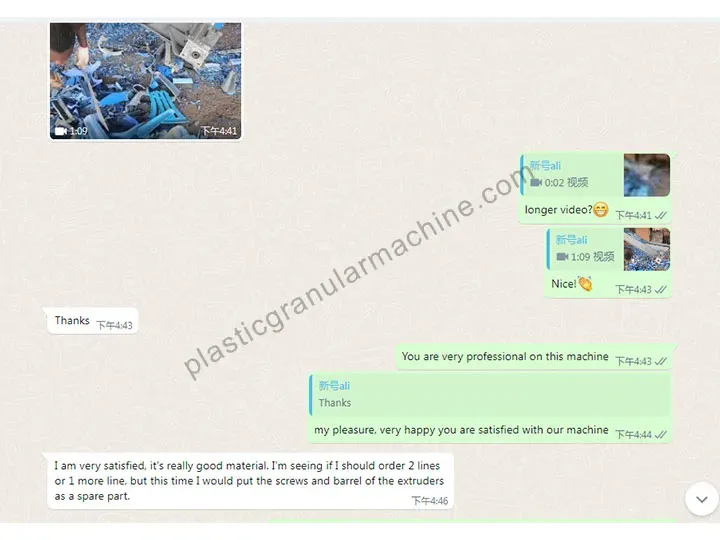

当社の HDPE プラスチック ペレット マシンは、ペットボトルやプラスチック ドラムなどの HDPE プラスチック硬質材料を処理するために設計された革新的なマシンです。ケニア、ナイジェリア、コートジボワール、サウジアラビア、その他のトーゴ諸国への輸出に成功しています。

私たちのマシンは完全なセットアップを完了しました プラスチックペレット化リサイクルライン 大量のHDPE廃棄物の処理をサポートし、最終的に高品質なプラスチックペレットを生産することで、お客様から高い評価をいただいています。

HDPEプラスチックリサイクルペレット化プロセス

- 溶融: 乾燥した HDPE ペレットは HDPE 顆粒製造機の溶融システムに供給され、そこで高温で溶融されて流動可能な状態に変化し、次の押出プロセスに備えます。

- 押出: 溶融した HDPE 材料が押出機を通過し、加熱されたスクリューによって押され、材料がさらに均一に加熱されてダイから押し出されます。

- 冷却:HDPE顆粒製造機から出たばかりのプラスチックストリップの温度は非常に高いため、冷却水タンクで冷却する必要があり、同時に冷却によりプラスチックが急速に硬化する可能性があるため、後続の HDPE プラスチックペレット化に便利です。

- 切断: 最後に、切断された HDPE ペレットを適切な長さに切断して、最終的なリサイクル ペレット製品を取得します。

HDPEペレット化機のパラメータ

次の 4 つのモデルは、当社のプラスチックペレット化機の最も人気のあるタイプであり、その機能はほとんどの顧客のニーズを満たすことができます。ただし、より大きなモデルが必要な場合は、カスタマイズすることもできますので、いつでもお気軽にお問い合わせください。

| 機械モデル | SL-125 | SL-150 | SL-180 | SL-200 |

| ネジ径 | 125mm | 150mm | 180mm | 200mm |

| 主軸速度 | 50~70/分 | 40~50/分 | 40~50/分 | 40~50/分 |

| メインモーター出力 | 30KW | 37KW | 55KW | 75KW |

| 減速機(ハードギヤ) | 225 | 250 | 280 | 315 |

| サイズ | 2.6*0.7*0.7 | 3.0*0.7*0.7 | 3.2*0.7*0.7 | 3.5*1*1 |

| 出力 | 180KG/H | 300KG/H | 350KG/H | 380KG/H |