ペットボトルリサイクルライン |ペットボトルリサイクル機

| 能力(kg/h) | 500-3000 |

| 原材料 | PETボトル、PETフレーク |

| コア機器 | ペットボトルリムーバー、粉砕機、プラスチック洗浄機 |

| コンベヤの数量 | 3-4 |

| プラスチック乾燥機の種類 | 水平 |

| マシンカラー | 白、黄 (カスタマイズをサポート) |

| アフター保証サービス | ビデオテクニカルサポート、オンラインサポート、フィールドメンテナンスおよび修理サービス |

技術的な詳細についてプロジェクト マネージャーに問い合わせることができるようになりました

ペットボトルリサイクルラインは、あらゆるペットボトルのリサイクルに特化した生産ラインです。コーラボトル、ソーダボトル、ペットボトル、ミネラルウォーターボトル、普通の水ボトル、その他のペットボトルをきれいなプラスチックフレークに加工できます。

これらのプラスチックフレークは、木材プラスチック系材料、サングラス、プラスチック椅子、携帯電話保護ケースなど、さまざまな製品に加工することができます。したがって、各国が環境保護を提唱している今日の環境では、ペットボトルのリサイクル工場に投資する。

PETリサイクルプラントのリサイクル原料と最終製品

PETリサイクルプラントの主原料は、廃棄されたPETボトルです。これらの廃棄されたボトルは、飲料ボトル、食品ボトル、スパイスボトル、化粧品ボトル、ビールボトルなど、さまざまな消費者のシナリオから発生する可能性があります。分散・包装どちらのボトルでもペットボトルリサイクル工場で対応可能です。

PETリサイクルプラントの最終製品はきれいなPETフレークであり、最終的にはボトルフレーク、繊維、シートなどの新しいPET製品を製造するためのリサイクルに使用されます。

以下の表に、最終的な PET フレークの基本データを示します。詳細な仕様については、当社のプロジェクト マネージャーから入手できます。

| パラメータ | データ |

| 水分 | 0.5-1% |

| フレークサイズ | 13-16mm |

| PVC 含有量 (ボトルラベル) | 100ppm |

| PP PE含有量(ボトルキャップ) | 200ppm |

| 金属含有量 | 20ppm |

ペットボトルリサイクル機の動画

ペットボトルのリサイクルとは何ですか?

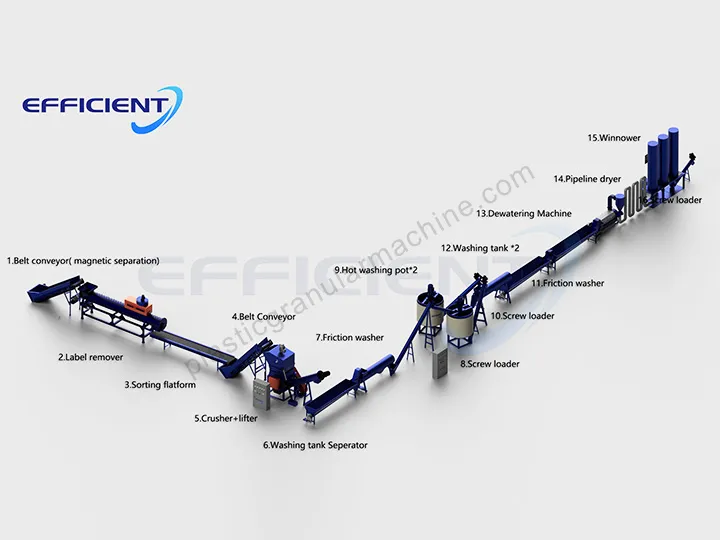

ペットボトルリサイクルラインの主なワークフローには、いくつかのステップが含まれます。

まず、ボトルのラベルをはがし、ペットボトルを細かく砕きます。

PETフレークはシンクフロート槽で洗浄分離され、PP PEフレークは水を媒体としてPETから分離されます。

高温洗浄と摩擦洗浄は、PET リサイクル プラントの次のステップです。

最後になりましたが、きれいな PET フレークは乾燥のために脱水機に送られます。一部の PET リサイクル プラントでは、最終ステップとしてプラスチック フレークを包装することを好みます。これらのリサイクル手順は静的なものではありません。

ペットボトルリサイクル装置をお客様のご要望に合わせてカスタマイズいたします。お客様ごとにリサイクル条件や原材料などが異なるため、お客様のニーズに合わせて個別にカスタマイズしたサービスをサポートします。

ペットボトルリサイクルプラントの技術仕様

PETリサイクルプラントの生産量がさらに多い場合は、お気軽にお問い合わせください。詳細については、こちらをご覧ください。

| リサイクル能力(kg/h) | 必要な面積 | 作業員の数 | 水使用量 (t/h) |

| 500 | 50*4m | 3~4人 | 2 |

| 1000 | 60*4m | 5~6人 | 3 |

| 2000 | 70*4m | 6~8人 | 4 |

PETリサイクルプラントのグローバルプロジェクト

ケース 1: コンゴペットボトルリサイクル機械プロジェクト

ケース 2: ナイジェリアプラスチックリサイクル機械プロジェクト

ケース 3: モザンビークのペットボトルリサイクル工場

ペットボトルリサイクルライン機械の詳細

次に、ペットボトルリサイクルラインに含まれるペットボトルリサイクル装置とその具体的な機能について詳しくご紹介します。

ペットボトルコンベヤベルト

当社のペットボトルコンベヤベルトは従来のコンベヤベルトとは異なります。ベルトコンベアには間隔をあけてバッフルが付いており、材料の飛散を防ぎます。全体のフレームはスチール、プーリー、ベルトで構成されています。同時に、作業者はこのステップで要件を満たさないペットボトルを選択することもできます。したがって、ペットボトルコンベアベルトには別名ペットボトルピッキングプラットフォームが付いています。

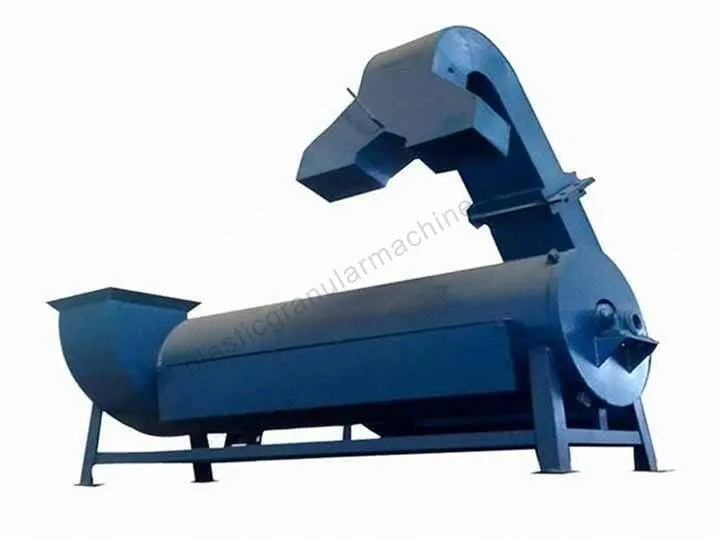

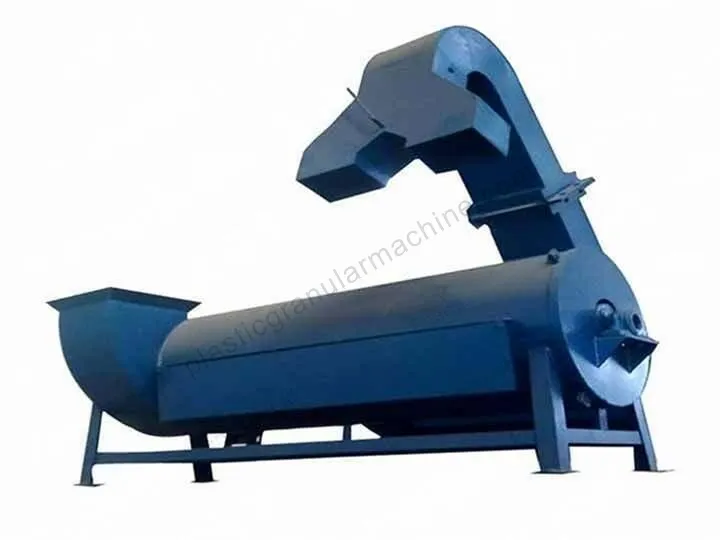

PETラベル剥離機

名前が示すように、 ペットボトルラベル剥がし機 ペットボトル本体のラベルを剥がす機械です。機械の中にはたくさんの歯車が入っています。機械の電源を入れると、ギアが前後に回転し、ラベルを剥がすことができます。ペットボトルラベルリムーバーの出口にあるファンにより、ラベルが吹き飛ばされて別の出口に飛ぶ可能性があります。手動によるオフマーキングと比較して、このオフマーキング方法は簡単かつ迅速です。同時に怪我のリスクも軽減します。

ペットボトルクラッシャー

の ペットボトルクラッシャー ペットボトルリサイクルラインの主力機の一つです。その目的はペットボトルを粉々に砕くことです。デバイス内には 9CrSi 製のメカニカルナイフが 10 個あります。したがって、PE、PP、PET、および PVC プラスチックを簡単に。特に大規模な機械生産に適しています。

ペットボトル用シンクフロートタンク

の プラスチックフレーク洗浄タンク プラスチック片を事前に洗浄できます。ペットボトル洗浄ラインでも重要な機械です。生産規模が比較的大きい場合は、洗浄タンクを構築する必要があることに注意してください。機械の内部にはネジ押し装置があり、一方では材料を前方に押し出し、他方では清掃のために破片を裏返すことができます。 PPやPEボトルのキャップとペットシートの分別にもお使いいただけます。

温水洗浄槽

ペットボトルには油汚れや粘液、染料などの汚れがどうしてもついてしまいます。適切な高温と適切な洗剤の混合により、製品の汚れを効果的に除去できます。私たちの気温は、 温水洗浄タンク 80〜90度に達することがあります。したがって、より優れた洗浄効果が得られます。

摩擦洗濯機

内部の高速回転スクリュー プラスチック製摩擦ワッシャー 素材を水で完全にこすることができます。それで。土、砂、葉、パルプなどの材料の表面の不純物を分離できます。この工程により、材料の徹底的な洗浄が実現されます。

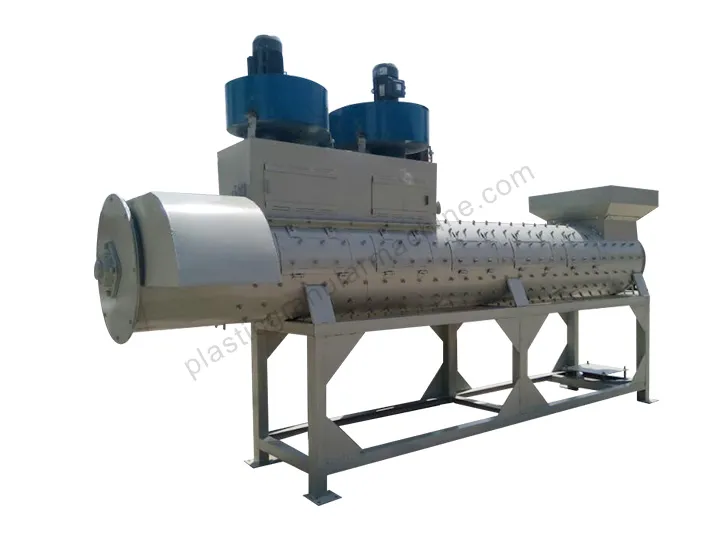

プラスチック脱水機

プラスチック脱水機 ペットボトルのリサイクルラインにおいて、破片の脱水・乾燥を行う最も重要な装置です。湿ったゴミはスクリューコンベアを通ってプラスチック脱水機の内部に運ばれます。遠心力の作用により、余分な水分と不純物が除去され、乾燥されます。したがって、乾燥した清潔で保管しやすい完成品が得られる。

収納ボックス

最後のペットボトルリサイクルラインの最後の機械は保管箱です。この装置には主にブロワー、パイプ、保管バレルなどが含まれます。ブロワーを使用して、乾燥したプラスチック破片を保管のために保管バレルに輸送します。これは便利かつ迅速であり、建設プロセス中に発生する可能性のある汚染を軽減します。

ペットボトルリサイクルラインは投資する価値があるのか?

答えは「はい」です。ペットボトルはリサイクル可能であり、幅広い用途に使用できます。ペットボトルの素材は食品グレードのPETだからです。割れにくく、透明度が高く、安全に使用でき、リサイクル価値が高いという特徴があります。インド国立化学研究所が発表したデータによると、インドのペットボトル回収率は90%であるのに対し、米国、日本、欧州ではそれぞれ29%、84%、60%となっている。

ペットボトルのリサイクルは当たり前になってきました。現在、世界中でリサイクルされたペットボトルのうち、プラスチックや不飽和ポリエステル製品に加工されているのはほんの一部です。残りのほとんどは繊維産業で使用されます。業界では再生繊維と呼ばれています。したがって、ペットボトルリサイクルラインの市場は大きい。

まとめ

つまり、当社のペットボトル洗浄ラインの特徴は次のとおりです。

- エネルギー効率が高く環境に優しい。

- 操作とメンテナンスが容易で、運用コストが低い。

- 当社のペットボトルリサイクルラインは 500 ~ 6000 kg/h の能力があり、生産要件に応じてカスタマイズできます。

- 幅広い用途に対応しており、原材料が他のプラスチックの場合も、当社にご相談いただければ、完璧なリサイクルソリューションを提供いたします。

あなたがしたい場合は PETリサイクルプラントを立ち上げる ペットボトルリサイクル機への投資など、お気軽にお問い合わせください。できるだけ早くご返信させていただきます。