Máquina granuladora de EPS | Granulador de espuma

| Tipo | 220/270/220/270/320/350 |

| Capacidad (KG/H) | 150-375 |

| Motor principal (kilovatios) | 15/18.5/15/18.5/18.5/22 |

| reductor | Doble/Individual |

| Garantía | un año |

Ahora puede solicitar detalles técnicos a nuestros jefes de proyecto

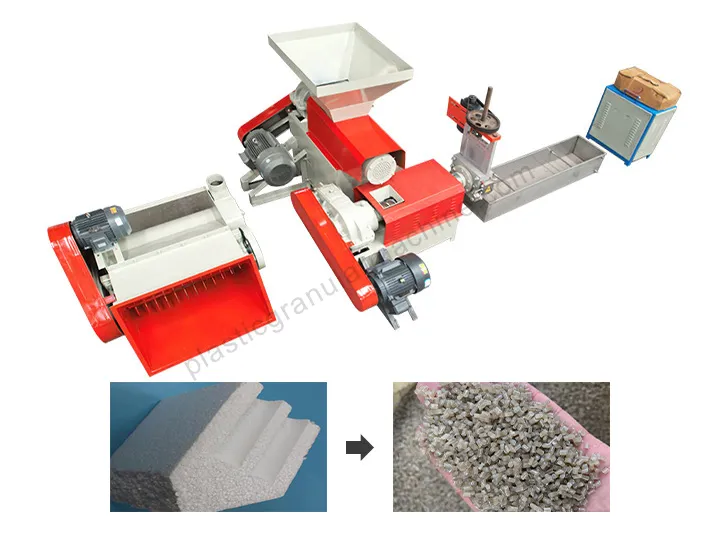

La máquina peletizadora de EPS es una máquina que transforma la espuma EPS de desecho en gránulos de EPS reciclables. Los gránulos de EPS se pueden usar en las industrias industrial, agrícola y de la construcción. Al mismo tiempo, la máquina peletizadora de EPS es también el equipo más importante en la línea de reciclaje de espuma EPS. Por lo tanto, esta máquina granuladora de poliestireno expandido desempeña un papel clave en el reciclaje de espuma EPS.

Características clave de los peletizadores de EPS eficientes

- Puede producir de forma automática y continua, asegurando la estabilidad del proceso de granulación y la calidad de los gránulos de EPS.

- Hecho de acero inoxidable de alta calidad, es duradero, resistente a altas temperaturas, resistente a la corrosión y no es fácil de deformar.

- El proceso de granulación de espuma de poliestireno se visualiza y está equipado con un gabinete de control inteligente, lo que facilita el seguimiento del proceso de granulación y controla estrictamente la temperatura, el tiempo, etc. durante el proceso de granulación de espuma plástica.

- Ocupa poco espacio, consume poca electricidad y produce productos de alta calidad.

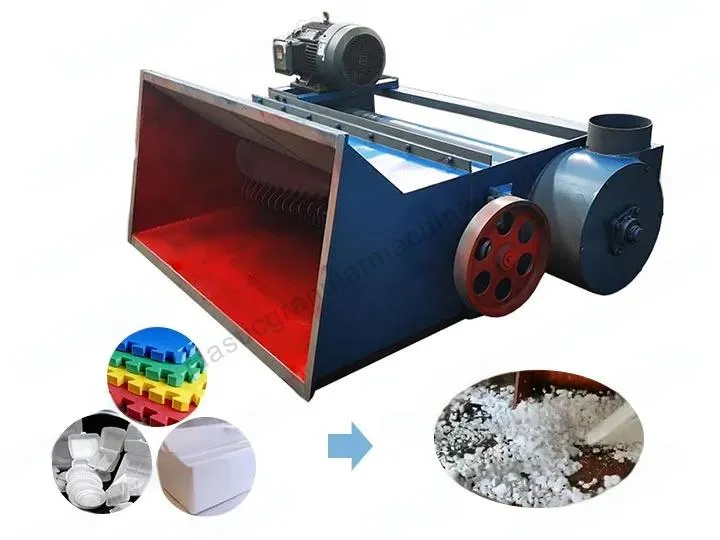

¿Cuáles son las materias primas y los productos finales del molinillo de espuma EPS?

Materias primas

Este granulador de EPS se puede utilizar para procesar varios tipos de residuos de espuma, como espuma aislante, poliestireno extruido, cajas de residuos de espuma, embalajes de espuma con aditivos, vajillas de espuma y EPE (polietileno expandido).

Productos finales

La máquina granuladora de EPS procesa residuos de espuma de poliestireno plástico en gránulos reciclados uniformes, que pueden usarse para fabricar nuevos productos plásticos en muchos campos, como embalaje, construcción, etc.

Además, al agregar diferentes pigmentos, agentes químicos, etc. durante el proceso de granulación, los gránulos de EPS pueden tener diferentes colores y propiedades para diferentes necesidades de producción.

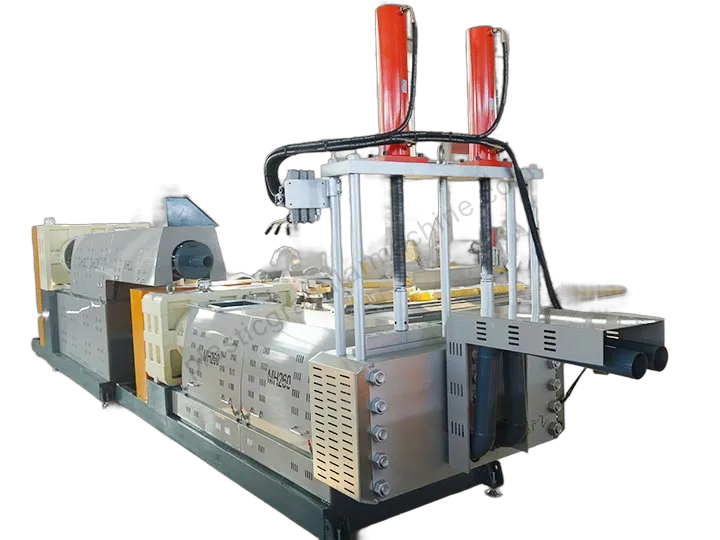

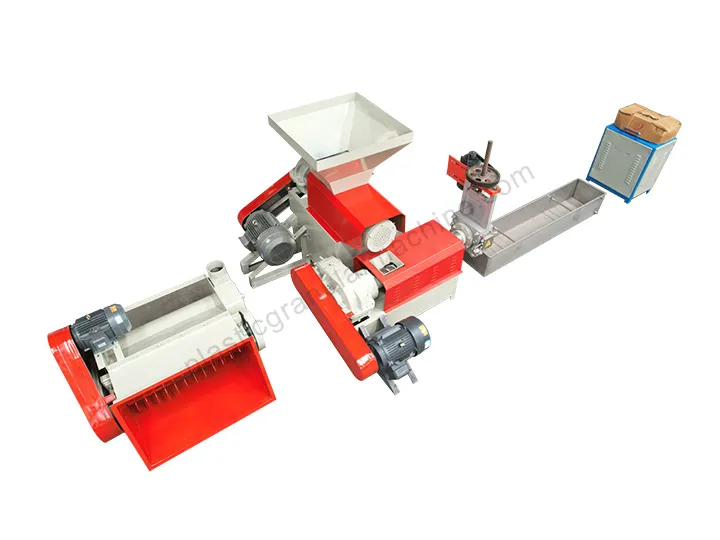

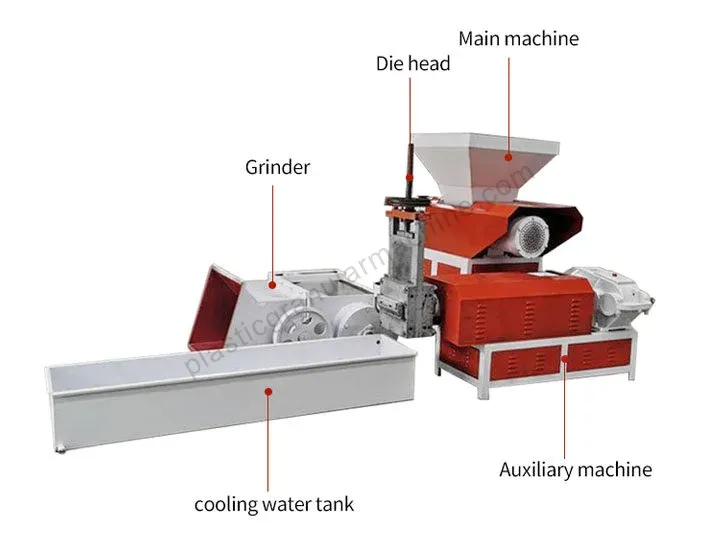

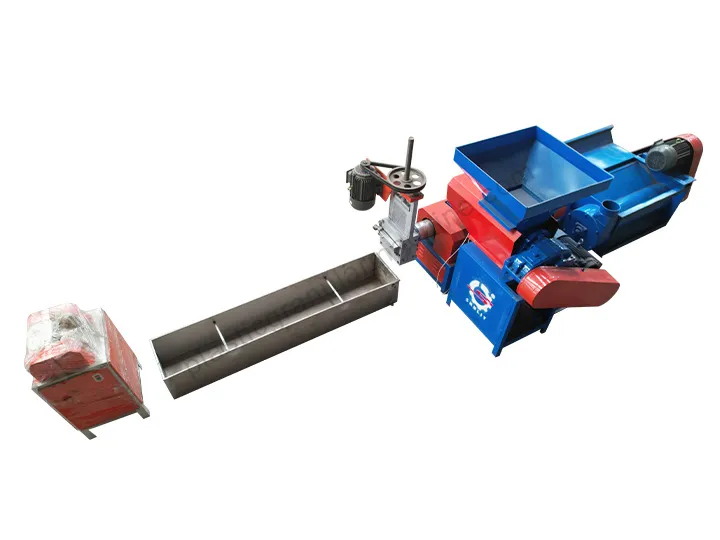

Estructura del granulador de EPS

Todo el sistema de granulación de espuma EPS incluye la máquina principal, la máquina auxiliar, el cabezal de troquel, la trituradora y la piscina de enfriamiento.

¿Cómo funciona una máquina granuladora de EPS?

El granulador de espuma EPS procesa los residuos de espuma EPS mediante métodos físicos o químicos como pretratamiento, fusión, granulación y granulación. En primer lugar, el host de granulación de EPS funde el plástico EPS y extruye la máquina auxiliar. Luego, el material en tiras largas se extruye desde la matriz auxiliar de granulación hacia la piscina de enfriamiento. Finalmente, la máquina cortadora de pellets corta la tira de EPS en pellets de EPS de tamaño uniforme. Tras esta serie de operaciones, podemos obtener pellets de espuma EPS. Este es todo el sistema de granulación de espuma EPS.

Parámetros de la máquina

| Tipo | Capacidad (KG/H) | Motor principal (kilovatios) |

| 220 (Doble Reductor) | 150-175 | 15 |

| 270 (Doble Reductor) | 220-225 | 185 |

| 220 (reductor único) | 150-175 | 15 |

| 270 (reductor único) | 220-225 | 18.5 |

| 320 (Doble Reductor) | 275-300 | 18.5 |

| 350 (Doble Reductor) | 325-375 | 22 |

Lo anterior son datos básicos de algunas máquinas peletizadoras de EPS de gran venta. Ofrecemos varios modelos y estilos para satisfacer las diferentes necesidades de granulación de poliestireno. También podemos proporcionar granuladores personalizados. Para obtener información específica, consulte a nuestro gerente de marketing.

¿Por qué es popular la máquina granuladora de EPS?

Por un lado, la vida está llena de todo tipo de productos de espuma EPS. Además, la espuma EPS se utiliza principalmente en cajas de espuma para refrigerios, cajas de espuma para conservación de alimentos frescos y materiales aislantes para alimentos. Al mismo tiempo, el EPS también es la espuma para embalaje de televisores, aires acondicionados, refrigeradores y otros muebles. Estos productos de EPS causarán una gran contaminación ambiental si no se reciclan. Por otro lado, la protección del medio ambiente se ha convertido en una moda. Varios países también abogan por la protección del medio ambiente. Por lo tanto, los peletizadores de EPS pueden generar muchas ganancias.

Aplicación de pellets de espuma EPS.

- En la vida diaria, los pellets reciclados pueden fabricar todo tipo de bolsas de espuma EPS, barriles, lavabos, juguetes, muebles, artículos de papelería y otros electrodomésticos.

- Ropa. Podemos utilizar bolitas de plástico EPS para fabricar ropa, corbatas, botones y cremalleras.

- Materiales de construcción. El derivado de los pellets de espuma EPS y los perfiles de madera plástica produce diversos componentes de construcción, puertas y ventanas de espuma EPS, etc.

- Suministros Industriales. Los pellets pueden fabricar tuberías, contenedores, bombas, válvulas, etc. Además, se pueden utilizar en plantas de producción química para solucionar la corrosión y el desgaste.

- Suministros agrícolas. Además, los pellets regenerados con espuma se pueden utilizar para fabricar películas agrícolas, tuberías de bombeo, maquinaria agrícola, fertilizante bolsas, sacos de cemento, etc.

- Además, los pellets reciclados fabricados con máquinas peletizadoras de espuma EPS también se utilizan ampliamente en la industria eléctrica y de telecomunicaciones.

El granulador de poliestireno expandido se usa a menudo junto con un triturador de espuma EPS, etc., para promover conjuntamente la producción de gránulos de EPS reciclados de alta calidad. Finalmente, si necesita equipos de reciclaje de plástico, no dude en contactarnos. Además, también tenemos un granulador de película plástica a la venta.

Máquina peletizadora de EPS eficiente exportada a Canadá

Recientemente, toda nuestra línea de reciclaje de espuma de poliestireno, incluido un granulador de EPS, se exportó con éxito a Vancouver para ayudar a una empresa de reciclaje de espuma de Vancouver a resolver el problema del equipo de reciclaje inadecuado. Como proveedor experimentado de maquinaria para el reciclaje de plástico, nos complace contribuir al reciclaje y utilización de los plásticos.

Entonces, si tiene dificultades con el reciclaje de plástico, ¡no dude en contactarnos!

Leer: ¿Cómo impulsamos el reciclaje de poliestireno expandido en Vancouver BC?

Nuestros servicios

- Hay máquinas personalizadas disponibles con un plazo de entrega de aproximadamente 20 días.

- ¡Bienvenido a nuestra fábrica para ver nuestras máquinas peletizadoras de EPS!

- Se enviará un vídeo de prueba antes del envío para confirmar que no hay errores.

- Brindamos soporte técnico y garantía de un año.

En resumen, nuestra máquina trituradora de espuma de poliestireno presenta alta calidad, alta eficiencia, etc. Si está buscando una excelente solución para triturar sus materias primas de espuma de desecho, seremos su mejor socio. ¡No dudes en contactarnos!