Lavadoras de botellas de plástico asequibles para sus plantas

Invertir en lavadoras de botellas de plástico rentables no solo puede ayudarle a completar la producción de rPET de alta calidad con la mitad del esfuerzo, sino que también puede reducir los costos para obtener más ganancias.

Características clave de nuestras lavadoras de botellas de plástico

- Utiliza un método de limpieza de tres etapas para una descontaminación eficiente y potente.

- Equipado con sistema de circulación de agua, ahorro de energía y protección del medio ambiente.

- La lavadora caliente adopta una nueva tecnología mejorada, profundizando y ampliando el tanque, lo que es más útil para descargar los chips de PET sin problemas.

- Fabricado en acero inoxidable de alta calidad, duradero, resistente al desgaste y resistente a altas temperaturas.

- Las escamas de botellas de PET limpias son de alta pureza y pueden usarse en envases de plástico, fibras, industrias de alta gama y otros campos, generando enormes ganancias.

¿Cómo realizar el proceso de lavado exhaustivo de botellas de PET?

El sistema de limpieza de tres etapas consta de una arandela de fricción, un tanque de separación del flotador del fregadero y un tanque de lavado caliente.

Lavadora de fricción

Los tanques de lavado más grandes y anchos pueden manejar grandes cantidades de desechos plásticos. El eje gira a alta velocidad, utilizando la fricción y el flujo de agua para eliminar la suciedad, adhesivos, etc. de las escamas de la botella.

El arandela de fricción de plástico tiene una capacidad de 500-2000kg/h, que puede eliminar eficazmente las impurezas, realizando el lavado inicial de botellas de plástico.

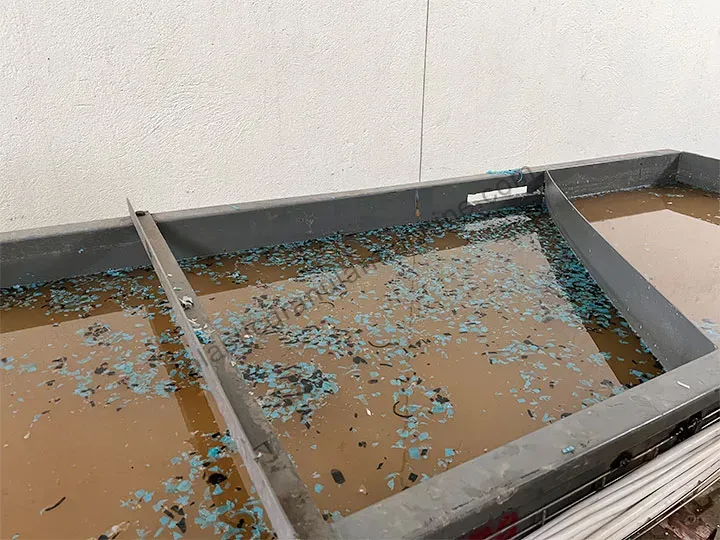

Tanque de flotador del fregadero

A continuación, el tanque de flotador de fregadero de plástico Proporciona una limpieza profunda de los trozos de botellas de plástico limpiados. El tanque Sink Float utiliza las diferentes densidades del material para separar eficazmente los contaminantes de las escamas de la botella.

Con una longitud de 6 metros y una altura de 1,2 metros, el tanque garantiza que los sedimentos y las tapas de las botellas se hundan eficazmente hasta el fondo, mientras que los restos ligeros de botellas de plástico flotan hacia la superficie y son transportados por la máquina al siguiente proceso de lavado.

Lavadora Caliente

El Lavadora caliente de escamas de botellas de PET está especialmente diseñado para lavar minuciosamente escamas de PET a altas temperaturas, lo que disuelve completamente el aceite, la grasa y otros contaminantes rebeldes.

La pureza de las escamas de las botellas de PET es de hasta 98% o más. Además, se pueden agregar reactivos químicos al proceso de lavado para modificar las escamas de PET y aumentar el valor de las escamas de rPET.

El efecto de nuestras lavadoras de botellas de plástico

La lavadora de botellas de plástico es el equipo clave en la industria del reciclaje de botellas de PET. La lavadora de botellas de PET de alta calidad puede garantizar una producción estable de escamas de botellas de PET de alta calidad, un alto reconocimiento en el mercado y un gran retorno de la inversión.

Conocidas por sus características de alta eficiencia y ahorro de energía, las lavadoras de botellas de plástico de Efficient Machinery se han vendido a Sudáfrica, Medio Oriente y otras regiones, contribuyendo en gran medida a la eficiencia de la empresa y la protección ambiental local.

Nuestros Servicios

- Para garantizar que cada unidad cumpla con estrictos estándares de calidad, contamos con un plazo de producción y puesta en servicio de 20 días, lo que garantiza que podamos brindarle equipos eficientes y duraderos.

- También le proporcionaremos actualizaciones en tiempo real sobre el progreso de la producción y la entrega durante el período de construcción.

- Brinda soporte tecnológico, instalación en sitio y garantía de un año.

En resumen

Estamos aquí para ayudarlo con cualquier desafío en el reciclaje de botellas de plástico. Si tiene preguntas o necesita una lavadora de botellas de plástico, ¡no dude en contactarnos!