EPS-Pelletiermaschine | Schaumgranulator

| Typ | 220/270/220/270/320/350 |

| Kapazität (kg/h) | 150-375 |

| Hauptmotor (KW) | 15/18.5/15/18.5/18.5/22 |

| Reduzierer | Doppelt/Einzel |

| Garantie | Ein Jahr |

Sie können jetzt unsere Projektmanager nach technischen Details fragen

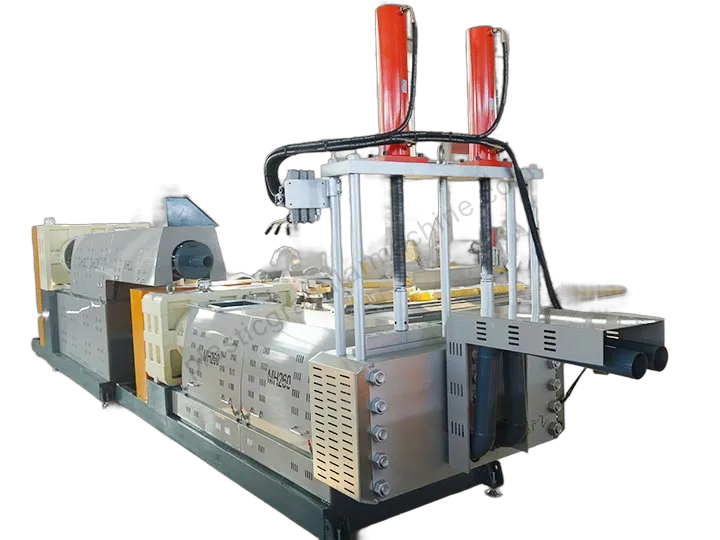

Die EPS-Pelletiermaschine ist eine Maschine, die überschüssigen EPS-Schaum in recycelbare EPS-Pellets umwandelt. EPS-Pellets können in der Industrie, Landwirtschaft und im Baugewerbe eingesetzt werden. Gleichzeitig ist die EPS-Granuliermaschine auch das wichtigste Gerät in der Branche EPS-Schaum-Recyclinglinie. Daher spielt diese Styroporgranulatormaschine eine Schlüsselrolle beim EPS-Schaumrecycling.

Hauptmerkmale effizienter EPS-Granulatoren

- Es kann automatisch und kontinuierlich produzieren und gewährleistet so die Stabilität des Granulationsprozesses und die Qualität der EPS-Pellets.

- Es besteht aus hochwertigem Edelstahl, ist langlebig, hochtemperaturbeständig, korrosionsbeständig und nicht leicht zu verformen.

- Der Styropor-Granulationsprozess wird visualisiert und mit einem intelligenten Schaltschrank ausgestattet, der es einfach macht, den Granulationsprozess zu verfolgen und Temperatur, Zeit usw. während des Kunststoffschaum-Pelletierungsprozesses streng zu kontrollieren.

- Es nimmt wenig Platz ein, verbraucht wenig Strom und produziert hochwertige Produkte.

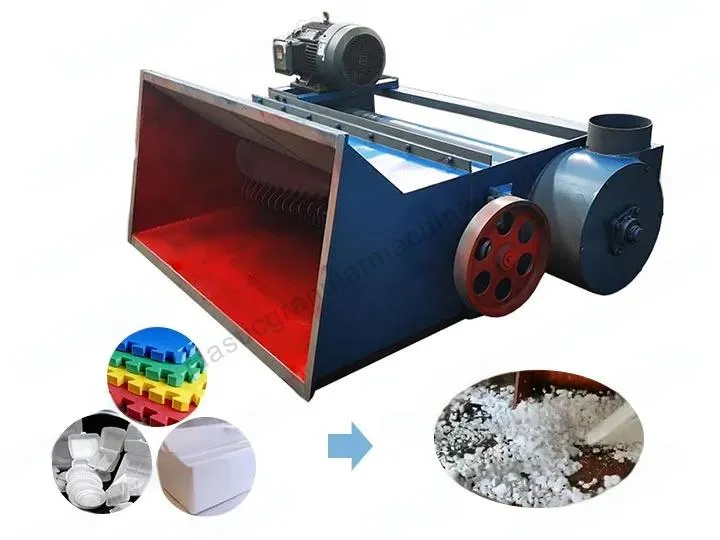

Was sind die Rohstoffe und Endprodukte der EPS-Schaummühle?

Rohstoffe

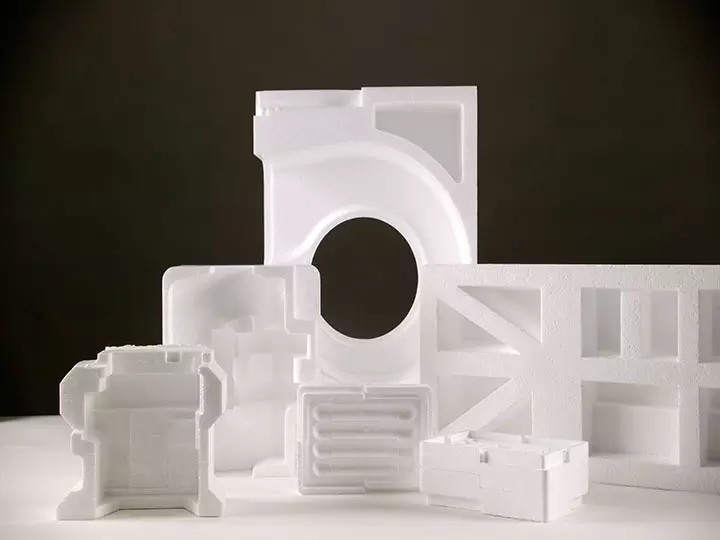

Mit diesem EPS-Granulator können verschiedene Arten von Abfallschaum verarbeitet werden, z. B. Isolierschaum, extrudiertes Polystyrol, Abfallschaumboxen, Schaumstoffverpackungen mit Zusatzstoffen, Schaumstoffgeschirr und EPE (expandiertes Polyethylen).

Endprodukte

Die EPS-Granuliermaschine verarbeitet Altkunststoff-Styropor zu gleichmäßig recycelten Pellets, die zur Herstellung neuer Kunststoffprodukte in vielen Bereichen wie Verpackung, Bauwesen usw. verwendet werden können.

Darüber hinaus können EPS-Granulate durch die Zugabe verschiedener Pigmente, chemischer Wirkstoffe usw. während des Granulierungsprozesses letztendlich unterschiedliche Farben und Eigenschaften für unterschiedliche Produktionsanforderungen aufweisen.

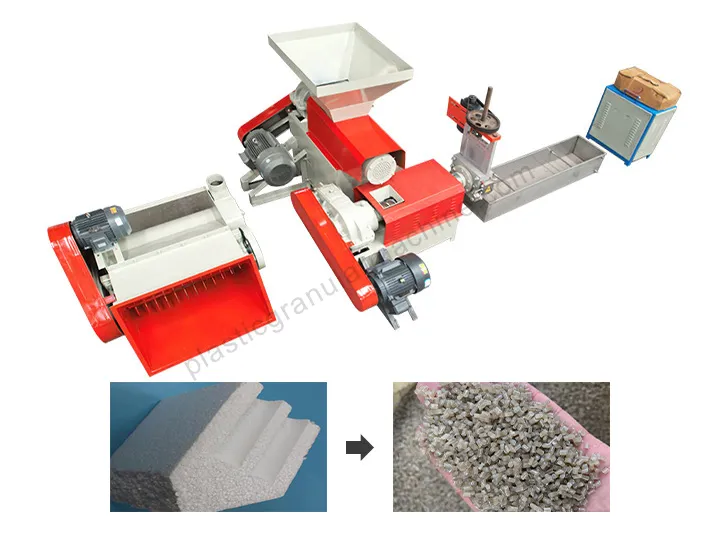

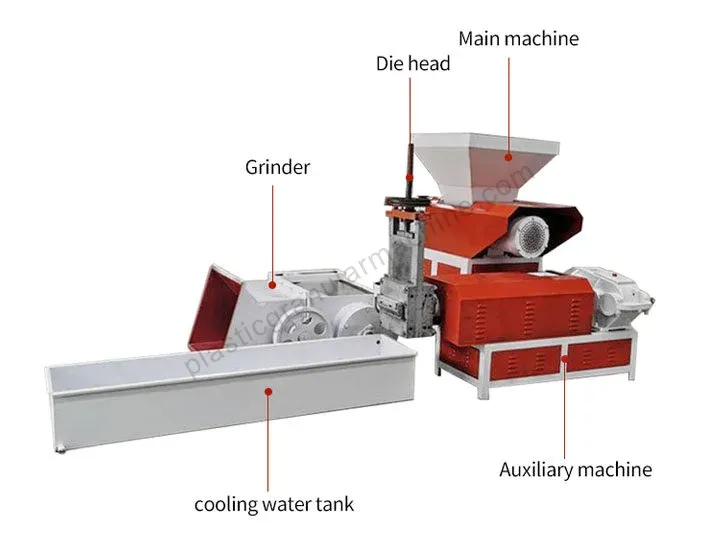

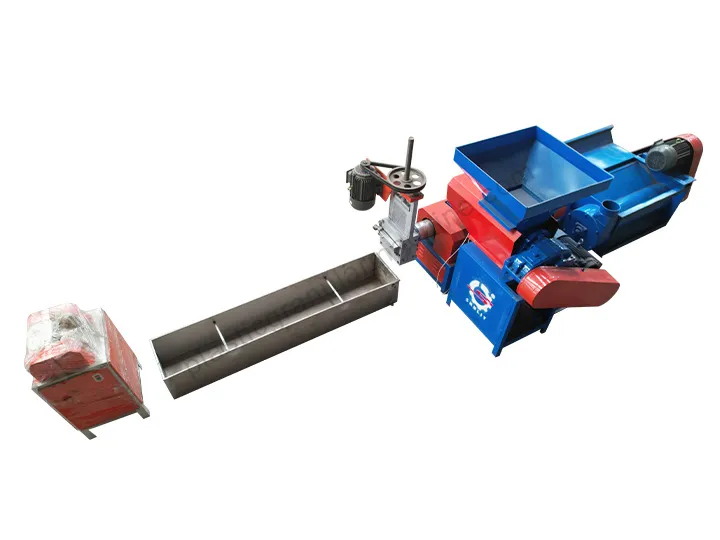

Aufbau des EPS-Granulators

Das gesamte EPS-Schaumgranulierungssystem umfasst die Hauptmaschine, die Hilfsmaschine, den Düsenkopf, das Mahlwerk und das Kühlbecken.

Wie funktioniert eine EPS-Pelletiermaschine?

Der EPS-Schaumgranulator verarbeitet Abfall-EPS-Schaum durch physikalische oder chemische Methoden wie Vorbehandlung, Schmelzen, Granulieren und Granulieren. Zunächst schmilzt der EPS-Granulationshost den EPS-Kunststoff und extrudiert die Hilfsmaschine. Anschließend wird das lange Bandmaterial aus der Granulierhilfsdüse in das Kühlbecken extrudiert. Schließlich schneidet die Pelletschneidemaschine den EPS-Streifen in EPS-Pellets mit einheitlicher Größe. Nach dieser Reihe von Arbeitsgängen können wir EPS-Schaumpellets erhalten. Dies ist das gesamte EPS-Schaumgranulierungssystem.

Maschinenparameter

| Typ | Kapazität (kg/h) | Hauptmotor (KW) |

| 220 (Doppelreduzierer) | 150-175 | 15 |

| 270 (Doppelreduzierer) | 220-225 | 185 |

| 220 (Einzelreduzierer) | 150-175 | 15 |

| 270 (Einzelreduzierer) | 220-225 | 18.5 |

| 320 (Doppelreduzierer) | 275-300 | 18.5 |

| 350 (Doppelreduzierer) | 325-375 | 22 |

Das Obige sind Grunddaten einiger heiß verkaufter EPS-Granuliermaschinen. Wir bieten verschiedene Modelle und Stile an, um den unterschiedlichen Anforderungen an die Pelletierung von Styropor gerecht zu werden. Wir können auch kundenspezifische Granulatoren liefern. Für spezifische Informationen wenden Sie sich bitte an unseren Marketingmanager.

Warum ist die EPS-Granuliermaschine beliebt?

Einerseits ist das Leben voller EPS-Schaumprodukte aller Art. Darüber hinaus wird EPS-Schaum hauptsächlich in Schaumstoff-Snackboxen, Schaumstoff-Frischhalteboxen und Isoliermaterialien für Lebensmittel verwendet. Gleichzeitig ist EPS auch der Verpackungsschaum von Fernsehgeräten, Klimaanlagen, Kühlschränken und anderen Möbeln. Diese EPS-Produkte verursachen eine große Umweltverschmutzung, wenn sie nicht recycelt werden. Andererseits ist Umweltschutz zur Mode geworden. Auch verschiedene Länder setzen sich für den Umweltschutz ein. Daher können EPS-Granulatoren große Gewinne erzielen.

Anwendung von EPS-Schaumpellets

- Im täglichen Leben können aus recycelten Pellets alle Arten von EPS-Schaumbeuteln, Fässern, Becken, Spielzeug, Möbeln, Schreibwaren und anderen Haushaltsgeräten hergestellt werden.

- Kleidung. Wir können EPS-Kunststoffpellets zur Herstellung von Kleidung, Krawatten, Knöpfen und Reißverschlüssen verwenden.

- Baustoffe. Aus EPS-Schaumpellets und Kunststoff-Holzprofilen werden verschiedene Bauteile, Türen und Fenster aus EPS-Schaum usw. hergestellt.

- Industriebedarf. Pellets können zur Herstellung von Rohren, Behältern, Pumpen, Ventilen usw. verwendet werden. Darüber hinaus können sie in chemischen Produktionsstätten zur Lösung von Korrosion und Verschleiß eingesetzt werden.

- Agrarbedarf. Darüber hinaus können schaumregenerierte Pellets zur Herstellung von landwirtschaftlichen Folien, Pumprohren, landwirtschaftlichen Maschinen usw. verwendet werden. Dünger Säcke, Zementsäcke usw.

- Darüber hinaus werden recycelte Pellets, die mit einer EPS-Schaumpelletiermaschine hergestellt werden, auch häufig in der Elektroindustrie und der Telekommunikationsindustrie verwendet.

Der Styropor -Granulator wird häufig in Verbindung mit einem verwendet EPS-Brecherusw., um die Produktion hochwertiger recycelten EPS-Pellets gemeinsam zu fördern. Wenn Sie Plastikrecycling -Geräte benötigen, können Sie uns bitte an uns wenden. Außerdem haben wir auch eine Kunststofffoliengranulator zu verkaufen.

Effiziente EPS-Pelletiermaschine, exportiert nach Kanada

Kürzlich wurde unsere gesamte Styropor-Recyclinglinie, einschließlich eines EPS-Granulators, erfolgreich nach Vancouver exportiert, um einem Schaumrecyclingunternehmen in Vancouver bei der Lösung des Problems unzureichender Recyclingausrüstung zu helfen. Als erfahrener Lieferant von Kunststoffrecyclingmaschinen freuen wir uns, zum Recycling und zur Nutzung von Kunststoffen beizutragen.

Wenn Sie also Probleme mit dem Recycling von Kunststoffen haben, zögern Sie bitte nicht, uns zu kontaktieren!

Lesen: Wie fördern wir das Recycling von Styropor in Vancouver, BC?

Unsere Leistungen

- Kundenspezifische Maschinen sind mit einer Vorlaufzeit von ca. 20 Tagen erhältlich.

- Willkommen in unserer Fabrik, um unsere EPS-Granuliermaschinen zu sehen!

- Vor dem Versand wird ein Testvideo gesendet, um zu bestätigen, dass keine Fehler vorliegen.

- Wir bieten technischen Support und eine einjährige Garantie.

Zusammenfassend lässt sich sagen, dass sich unsere Styropor-Mahlmaschine durch hohe Qualität, hohe Effizienz usw. auszeichnet. Wenn Sie nach einer großartigen Lösung zum Mahlen Ihrer Schaumstoff-Abfallrohstoffe suchen, sind wir Ihr bester Partner. Zögern Sie nicht, uns zu kontaktieren!