EPS-Verdichter zum Recycling von Styropor-Polystyrol

| Modell | SL-400 |

| Kapazität | 250kg/h |

| Einlassgröße | 1200*1000mm |

| Motorleistung | 22 kW |

| Maschinengröße | 4600*1600*1600mm |

Sie können jetzt unsere Projektmanager nach technischen Details fragen

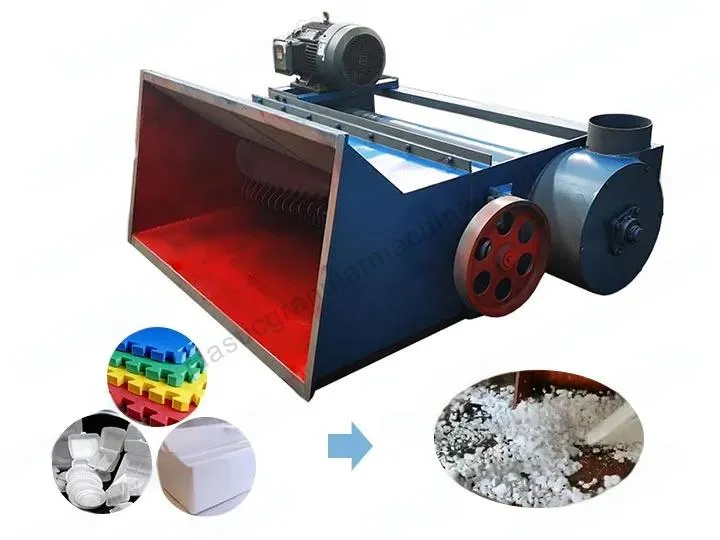

Der EPS-Verdichter wird auch als Polystyrol-Verdichter und EPS-Styropor-Recycling-Verdichter bezeichnet. Dabei handelt es sich um eine Maschine, die große Schaummengen zu Schaumstoffblöcken mit hoher Dichte verdichten kann.

Der EPS-Verdichter kann das Schaumvolumen um das 40-fache reduzieren. Es zeichnet sich durch einen hohen Automatisierungsgrad, Energieeinsparung und Schadstofffreiheit aus.

Was sind die Vorteile des effizienten Schaumverdichters?

- Der Styroporverdichter ist mit einer Zerkleinerungsvorrichtung ausgestattet, die große Schaumstoffplatten direkt zerkleinern kann.

- Die Dichte des durch Styroporverdichter komprimierten Schaums ist hoch, wodurch der EPS-Schaum um das 40-fache komprimiert werden kann.

- Am vorderen Ende des Kompressionsgeräts befindet sich eine Druckregelvorrichtung, mit der das Kompressionsverhältnis eingestellt werden kann.

- Komprimierte Schaumstoffblöcke lassen sich leicht schneiden, lagern und stapeln.

- Beim Betrieb der Maschine entsteht kein eigenartiger Geruch.

- Komprimierte EPS-Materialien können recycelt werden.

- Die Größe der EPS-Verdichtungsmaschine kann je nach Kundenwunsch angepasst werden

Wie funktioniert die EPS-Verdichtungsmaschine?

- Zuerst müssen wir den EPS-Schaum in den Trichter füllen.

- Anschließend gelangt der EPS-Schaum zur Zerkleinerung in die Brechkammer. Der am Eps-Verdichter angebrachte Zerkleinerer kann große Schaumstücke in kleine Stücke zerkleinern.

- Dann drückt der Schraubmechanismus kleine Stücke aus EPS-Schaum in einen Kompressionsblock mit quadratischem Querschnitt.

EPS-Verdichter zu verkaufen

| Modell | SL-300 | SL-400 |

| Kapazität | 150kg/h | 250kg/h |

| Einlassgröße | 1100*800mm | 1200*1000mm |

| Motorleistung | 11 kW | 22 kW |

| Maschinengröße | 3000*1400*1400mm | 4600*1600*1600mm |

Das Obige ist die Parametertabelle von zwei Styroporverdichtern. Ihre Leistung beträgt 150 kg/h bzw. 250 kg/h. Die Motorleistung beträgt 11 kW bzw. 22 kW. Je nach Bedarf können Sie den passenden Styroporverdichter auswählen.

Warum wird Polystyrol-Verdichter immer beliebter?

Heutzutage legen Länder großen Wert auf die Umweltschutzindustrie. Die Verbrennung von EPS-Schaum wird zunehmend unerwünscht. Daher entscheiden sich immer mehr Menschen dafür, in die EPS-Recyclingbranche zu investieren. Um EPS-Schaum bequemer transportieren zu können, ist ein Polystyrol-Verdichter erforderlich, der das Schaumvolumen reduziert.

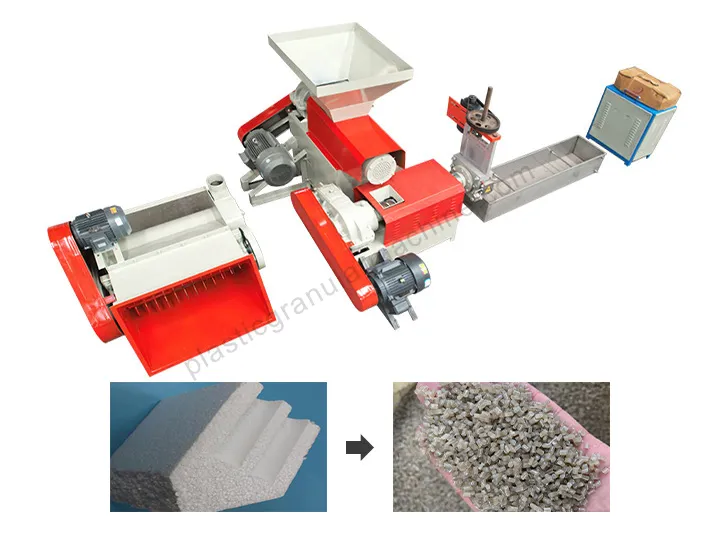

Daher erfreuen sich Styroporverdichter immer größerer Beliebtheit. In der Fabrik für effiziente Kunststoffrecyclingmaschinen haben wir auch die EPS-Granulator, EPS-Brechermaschineund EPS-Recyclinglinie zu verkaufen. Wenn Sie einen verwandten benötigen EPS-Recyclingmaschine, nehmen Sie gerne Kontakt zu uns auf.

Erfolgsbeispiele von Styroporverdichtern zum Verkauf

Im September 2022, Malaysische Kunden bestellten zwei EPS-Styropor-Recycling-Verdichter. Dieser Kunde verfügt über eine Recyclinganlage für EPS-Schaum. Neben der Produktion von komprimierten Schaumstoffblöcken stellt er auch EPS-Granulat her. Nach fast zwei Monaten Einsatz ist der Kunde mit der Produktionswirkung des Schaumverdichters sehr zufrieden.

Vorsichtsmaßnahmen für den Betrieb

- Bitte bestätigen Sie die von der Maschine verwendete Stromversorgung.

- Stecken Sie Ihre Hand während des Betriebs nicht in den Materialkasten, das Getriebeteil oder das Heizteil.

- Tragen Sie während der Operation eine spitze Maske und einen Gehörschutz.

- Spülen Sie die Maschine nicht direkt mit Wasser aus. Arbeiten Sie nicht barfuß, wenn der Arbeitsplatz nass ist.

- Wenn der EPS-Verdichter nicht verwendet wird, decken Sie bitte den Behälter ab, um zu verhindern, dass andere Gegenstände hineinfallen.

- Wenn das Gerät nicht verwendet wird, trennen Sie es unbedingt vom Stromnetz

- Tauschen Sie Teile an der Maschine nicht nach Belieben aus.

- Die Hauptteile müssen regelmäßig mit Öl geschmiert werden.

- Der Styroporverdichter kann an Ihre Produktionsanforderungen angepasst werden und die Produktionszeit beträgt etwa 20 Tage.

- Versenden Sie regelmäßig Updates zum Produktionsfortschritt und testen Sie Maschinenvideos. Bestätigen Sie vor dem Versand die Informationen zum Schaumkompressor mit Ihnen.

- Wir heißen Sie herzlich willkommen, unsere effiziente Fabrik zu besuchen und unsere EPS-Kompressoren zu inspizieren.

- Versand durch internationale Logistik.

- Bieten Sie technischen Support und Installationsdienste vor Ort.

- Eine einjährige Garantie gewährleistet die Qualität der Maschine.

Zusammenfassend lässt sich sagen, dass unsere EPS-Verdichter zuverlässig und hochwertig genug sind. Wenn Sie nach einer großartigen Lösung für das Styropor-Recycling suchen, zögern Sie bitte nicht, uns zu kontaktieren. Es erwarten Sie tolle Angebote zu unschlagbaren Preisen!