Wie können potenzielle Sicherheitsrisiken einer EPS-Schaumpelletiermaschine vermieden werden?

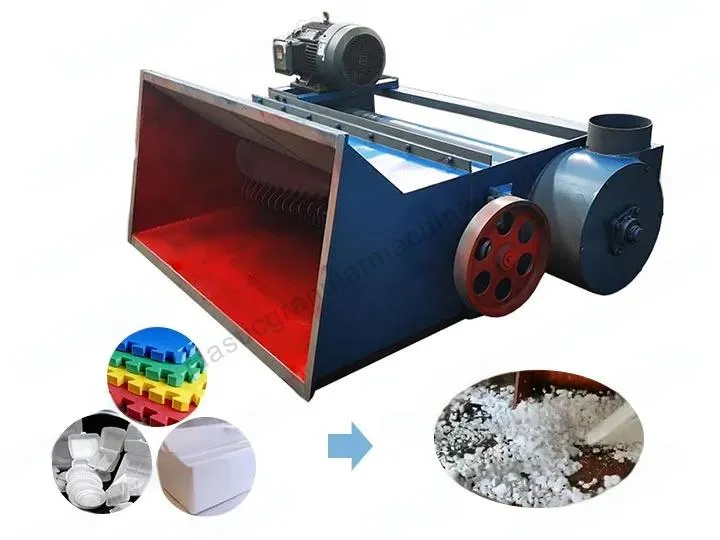

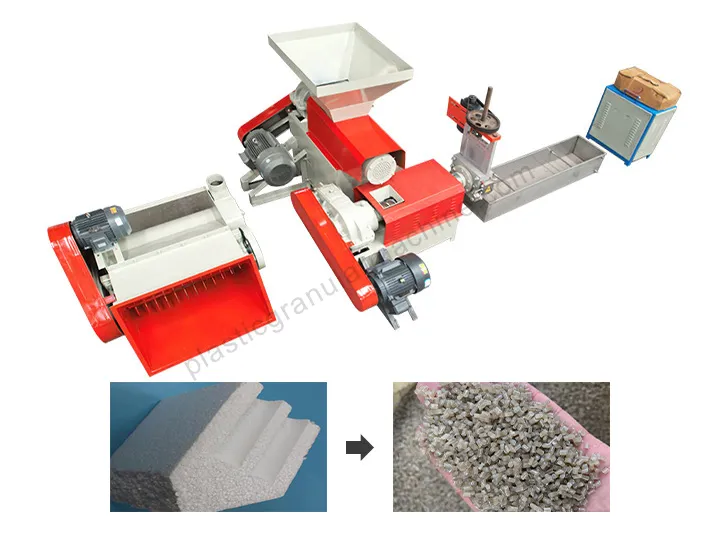

Die Pelletiermaschine für EPS-Schaum ist eine gängige Verarbeitungsanlage für Kunststoffe. EPS-Kunststoffpartikel werden häufig in der chemischen Industrie, der Medizin, beim Drucken und Färben und in anderen Bereichen eingesetzt. Beim Betrieb von EPS-Granulatoranlagen sollten wir auf die Sicherheit achten. Worauf sollten wir also achten?

Vorsichtsmaßnahmen für die Verwendung einer EPS-Schaumpelletiermaschine

- Nach dem Kauf des EPS-GranulatorLesen Sie unbedingt die Installationsanweisungen für den Kunststoffgranulator sorgfältig durch und bedienen und installieren Sie ihn gemäß den Anweisungen.

- Überprüfen Sie, ob die Muttern und Sicherheitsabdeckungen jedes Teils locker sind. Ziehen Sie von Hand an der Kupplung oder Keilriemenscheibe, um zu prüfen, ob das Übertragungssystem normal ist.

- Prüfen Sie, ob der Schaltschrank über einen Erdungsschutz und einen Not-Aus-Taster verfügt.

- Prüfen Sie, ob die Strom-, Wasser-, Druckluft-, Heizungs- und Kühlsysteme angeschlossen sind und ob Leckagen vorliegen.

- Die EPS-Schaumpelletiermaschine muss den Matrizenabstand entsprechend den Anforderungen an die Produktdicke richtig einstellen.

Wie wird die EPS-Schaumgranulatormaschine gewartet?

- Überprüfen Sie regelmäßig, ob die Sicherheitsvorrichtung der EPS-Schaum-Granuliermaschine ordnungsgemäß und wirksam ist, insbesondere nach dem Austausch der Form, und prüfen Sie, ob die mechanische Versicherung entsprechend angepasst wurde.

- Überprüfen Sie regelmäßig den Anschluss des Erdungskabels, die Isolierung elektrischer Komponenten und die Alterung der Kabel.

- Überprüfen Sie regelmäßig die Rohrleckage der EPS-Schaum-Granuliermaschine und den Befestigungszustand der Befestigungselemente.

- Überprüfen Sie regelmäßig, ob die Schmierpumpe und der Grundöltank ausreichend Öl haben.

- Überprüfen Sie die Zuverlässigkeit des Schmiersystems und schmieren Sie die beweglichen Teile bei Bedarf.

- Überprüfen Sie regelmäßig den Zustand des Ölfiltersiebs oder des Öleinfüllstutzens.

- Wenn das Hydrauliköl dunkelbraun wird und stinkt, ist das ein Zeichen von Oxidation und Verschleiß. Das Hydrauliköl sollte so schnell wie möglich erneuert werden. Wenn das Hydrauliköl kleine schwarze Flecken oder transparente helle Flecken aufweist, weist dies darauf hin, dass Verunreinigungen oder Metallpulver eingemischt sind und das Öl gefiltert oder ersetzt werden sollte.

- Der Kühler der EPS-Schaumgranulatormaschine muss eingeweicht und gereinigt werden Kohlenstofftetrachlorid Lösung alle 5-10 Monate.

- Die Wartung der Schnecke, des Zylinders und anderer wichtiger Teile des Kunststoffgranulators muss gemäß den Anweisungen durchgeführt werden.

Zusammenfassung

Sicherheit ist für jede Produktion wichtig. Deshalb sollten wir eine EPS-Schaum-Granuliermaschine gemäß den Spezifikationen installieren und betreiben sowie diese regelmäßig warten und reparieren. Auf diese Weise können Sicherheitsprobleme weitestgehend vermieden werden.