Einige Tipps zur Verwendung des EPS-Granulators

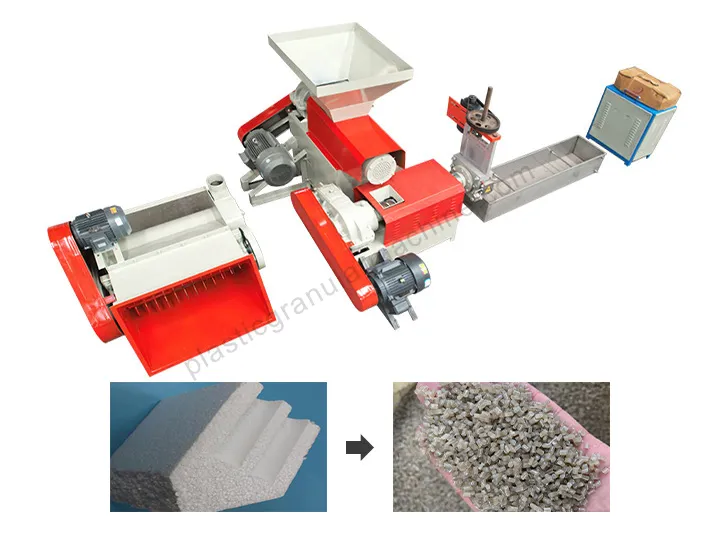

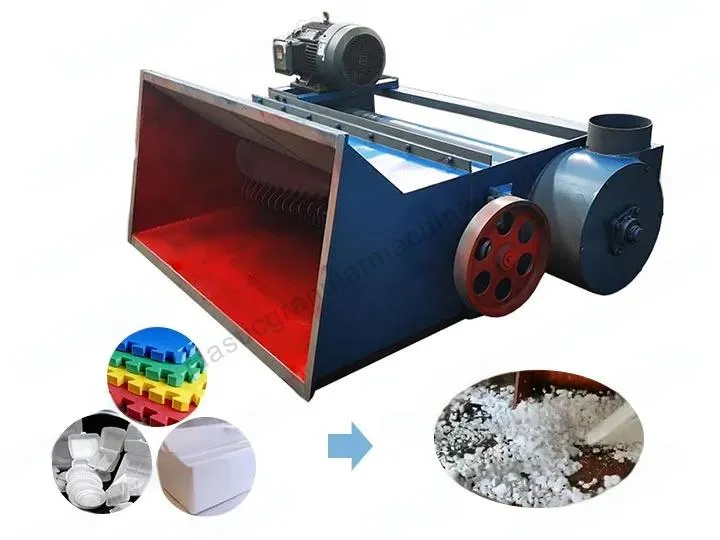

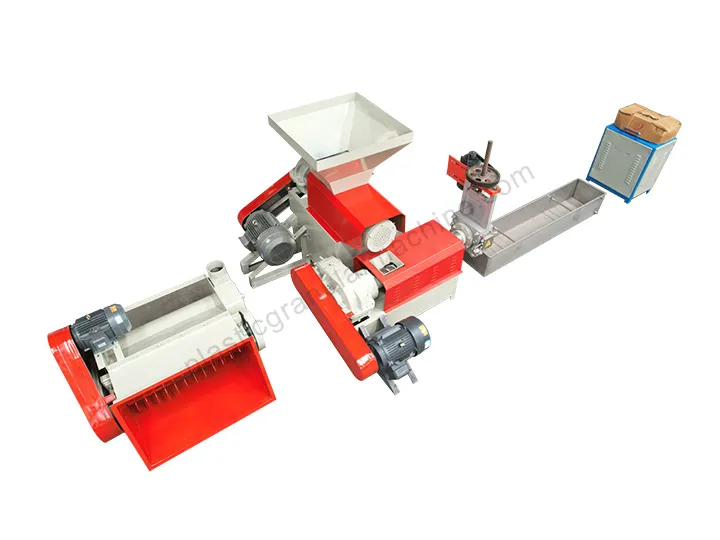

Der EPS-Granulator ist eine wichtige Maschine zur Herstellung von EPS-Granulat. Bei der Verwendung können einige Probleme auftreten. Wir stellen vor, wie man hochwertige EPS-Partikel herstellt.

Wie regelt man die Temperatur, wenn der EPS-Granulator läuft?

Beim Start des EPS-Granulators kann die Temperatur der oberen Schnecke auf etwa 200 °C eingestellt werden. Die untere Schneckentemperatur kann auf ca. 160 °C eingestellt werden. Dies dient zur Anpassung der Temperatur an die extrudierten Materialien bei der Herstellung trockener Materialien. Zweitens: Wechseln Sie häufig das Filtersieb. Dadurch kann die Qualität und Transparenz der Partikel sichergestellt werden.

Das Filtersieb des EPS-Granulator kann entsprechend den Anforderungen an die Produktqualität zwischen 40 und 100 Maschen ausgewählt werden. Je höher die Maschenzahl des Filtersiebs ist, desto sauberer werden die Verunreinigungen gefiltert.

Durch die Steuerung der Kühlwassertemperatur kann sichergestellt werden, dass die geschnittenen Partikel eine bestimmte Temperatur haben, um das Wasser auf der Partikeloberfläche zu verdampfen.

Wie stellt man hochwertige EPS-Partikel her?

- Der Kauf einer qualifizierten EPS-Granuliermaschine ist eine Grundvoraussetzung

- Der zweite ist der Einfluss der Produktionsumgebung.

- Es ist auch wichtig, die richtigen Operationsmethoden anzuwenden. Die Gründe für schlechte Kornqualität und ungleichmäßigen Austrag sollen geklärt werden.

- Die Spannung muss stabil sein. Wenn der EPS-Granulator arbeitet, wird Strom verwendet, um den Betrieb der Maschine anzutreiben. Wenn die Stromspannung instabil ist, ändern sich Geschwindigkeit und Kraft der Maschine. Wenn die Spannung stabil ist, erfolgt das Schneiden und Entladen der EPS-Partikel gleichmäßig. Wenn die Spannung jedoch instabil ist, wird sie unregelmäßig. Dies führt zu einer ungleichmäßigen Partikelabgabe.