How To Produce Foam Granules With Styrofoam Recycling Machines?

Do you want to recycle styrofoam and produce high-quality renewable pellets? Then I suggest starting with the following steps:

- Understanding the styrofoam recycling process.

- Optimizing the granulation process.

- Regular maintenance and upgrading of equipment.

How Exactly Should I Proceed with?

The Detailed Guide of EPS Foam Recycling

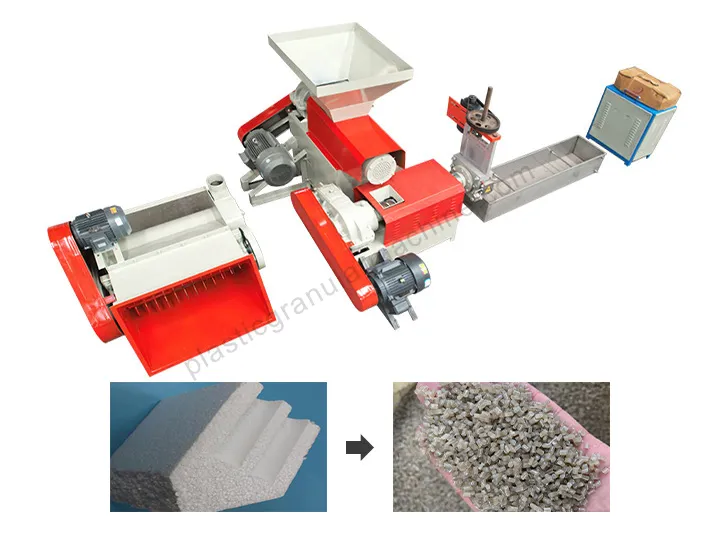

The expanded polystyrene recycling processes can be divided into crushing, pelletizing, and so on.

Firstly, crush bulky styrofoam into small pieces for subsequent processing by a foam shredder; then use the EPS pelletizing machine for melting, extruding, cooling, and cutting to get uniform high-quality pellets. It is then dewatered for storage using the plastic drying machine.

How to Optimize the Granulation Process

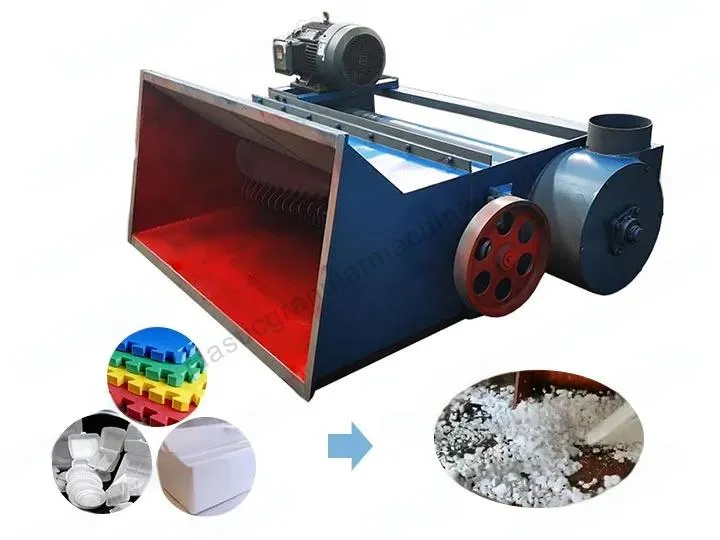

- Improvement of crushing technology: Use of high-efficiency styrofoam shredder to ensure that the polystyrene can be uniformly broken into smaller particles, which is convenient for subsequent processing.

- Optimization of foam densification: Use of styrofoam densifiers or EPS briquetting machines to reduce the volume of plastic styrofoam for storage and transportation, thereby increasing the polystyrene recycling efficiency.

- Strict control of the granulation process: Select an accurate and efficient pelletizing system to control pellet density and ensure uniformity. At the same time, tightly control the granulating temperature to avoid overheating or overcooling, which can affect pellet quality and performance.

Regular Maintenance

Regular maintenance checks on the styrofoam recycling machine keep the equipment in optimum working condition and help to prolong the life of the machine.

Why I Need to Produce Granules With Styrofoam Recycling Machines?

Waste foam plastic is bulky and not easy to handle. Pelletizing with styrofoam recycling machines enhances the value of foam waste while facilitating storage and transportation.

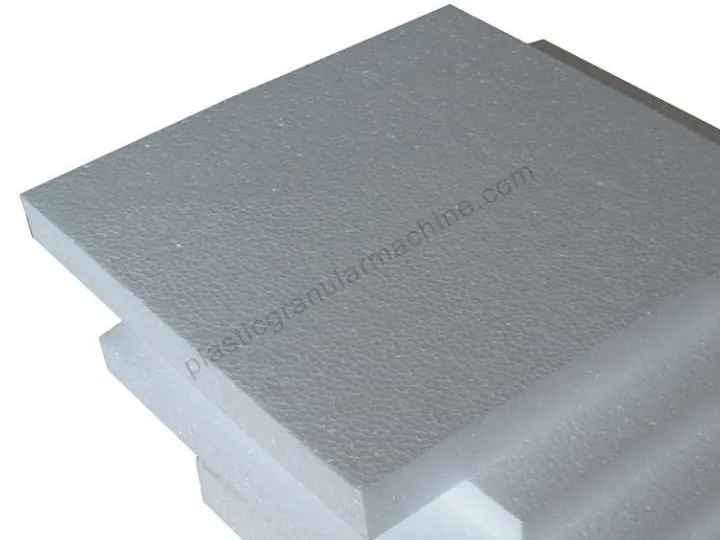

The granulated foam is more suitable for subsequent production processes. Uniform and smooth foam particles are more conducive to strict quality control during the production process and efficient production.

For better pelletizing, the use of efficient and automated styrofoam recycling machines can ensure continuous and stable production, improve styrofoam plastic recycling efficiency and reduce labor costs.

In addition, the advanced EPS recycling line can make the granules’ size, density, etc., more uniform and better remove the impurities in the foam raw material, producing higher-quality recycled particles and enhancing the market’s competitiveness.

What Are the Standards for High-Quality Foam Granules?

- High uniformity: The foam granules should have good uniformity and consistency in terms of size, density, etc., which is more conducive to the quality of the final products for subsequent production.

- High purity: Excessive mixing of dirt, glue and other impurities can affect the quality of the final product. High quality foam particles should have a high degree of purity.

- Odorless: No unpleasant pungent odors, indicating that the expanded polystyrene was adequately cleaned during the recycling process.

Invest In Efficient And Eco-friendly Styrofoam Recycling Machines

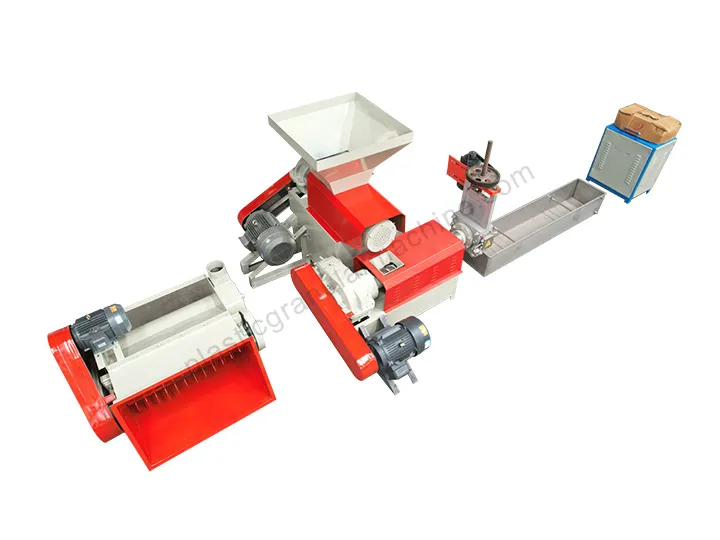

To summarize, investing in advanced styrofoam recycling machines can boost your business. We offer polystyrene shredding machines, styrofoam compactors, styrofoam melters, and EPS pelletizers. You are free to match and customize them according to your specific production needs!

Our expanded polystyrene recycling line is known for its high efficiency and low energy consumption; it adopts advanced screw melting technology, which effectively filters out impurities and waste residue, and helps to improve the uniformity and purity of the recycled EPS pellets.

How Can High-quality Recycled Granules Be Utilized?

After the waste foam is recycled into renewable pellets, these high-quality foam pellets can be used in the following applications:

- Manufacture of new foam products: e.g. packaging materials, sofa fillings, insulation materials, etc.

- Construction: lightweight concrete aggregate, etc.

- Automotive: production of automotive parts, etc.

Foam recyclers can sell the pellets to product manufacturing companies at a profit; foam producers can also do post-industrial in-house recycling to reduce production costs. Please tell us about your production situation and we will design the most suitable styrofoam recycling machines and solutions for you!