How To Set Up A Small Foam Recycling Plant?

Small foam recyclers are often unable to recycle plastic foam efficiently due to location, budget, or equipment constraints. This article provides sound advice for entrepreneurs looking to start or improve their foam recycling plants.

Plastic Foam Materials You Should Know

First, you need to understand the different foam raw materials and determine the type required for production in your plant.

- EPS: Light weight, heat insulation, good cushioning effect, widely used in packaging boxes, building insulation, etc.

- EPE: Soft, impact resistant, widely used in electronic products, fruit packaging film, etc.

- XPS: Rigid foam insulation, high density, widely used in construction industry.

Read more about the differences in this article: The differences and uses of EPS, EPE, and EPP

Proceesing Guide for Small Foam Recycling Plant

Reducing Styrofoam Volumes

Plastic foam is known for its large volume and light weight, which means it takes up significant storage space. Consequently, small facilities with limited space can compress it to save room. EFFICIENT can provide the following two specialized EPS foam compression solutions:

EPS styrofoam compactor: Through the mechanical force of the hydraulic system, it compresses the loose foam into dense blocks with a volume reduction of 40 times, without consuming heat and with low energy consumption. The EPS compactor is easy to operate and suitable for processing dry foam, suitable for small foam recycling plants seeking energy saving and with limited budget.

Polystyrene Melter: Through the screw melting and extrusion, the foam will be converted into dense lumps, the compression effect is more significant, it can deal with a wide range of foam types, suitable for factories with a large amount of foam waste.

If you are not sure how to choose, or looking for customized equipment to meet your needs, please feel free to contact us.

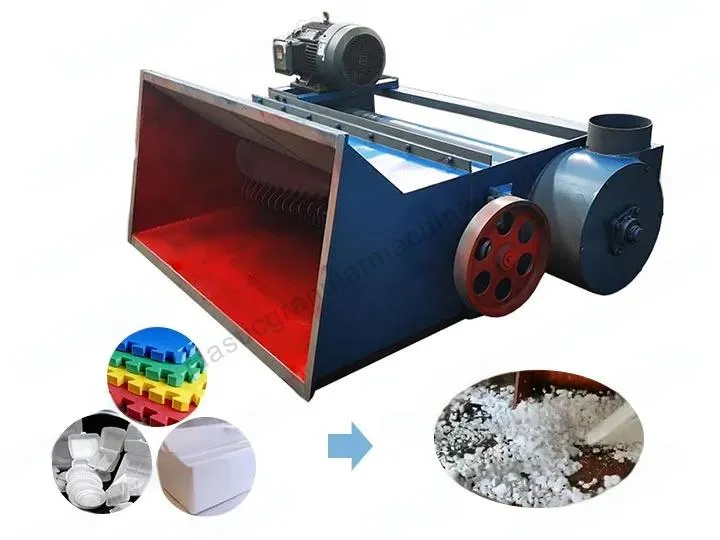

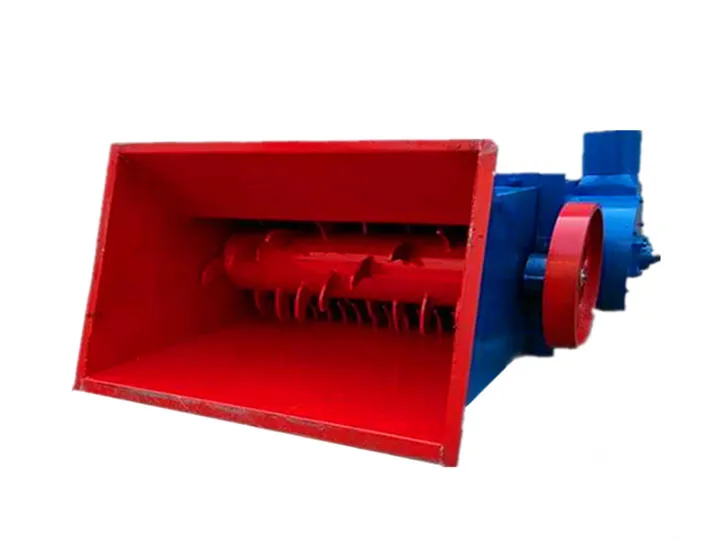

Shredding EPE EPS Foams

In the plastic foam recycling process, the EPS crusher is used to shred bulky foams into uniform small pieces, which facilitates the subsequent granulation process and improves the efficiency of foam recycling.

Direct processing of loose EPS, EPE, EPP, etc.

Several popular models with capacities ranging from 250 to 500 kg/h.

For harder foam slabs or ingots, this 1.5t/h foam crusher can be used. We can also provide custom-designed crushers to meet the production needs of your foam recycling facility.

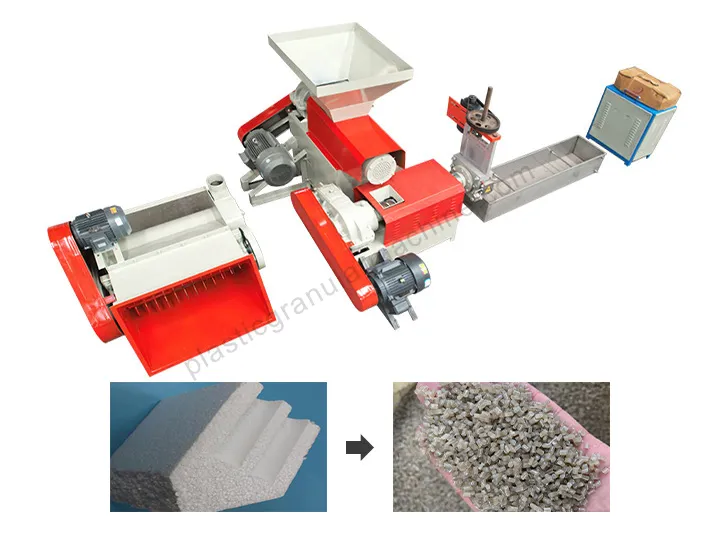

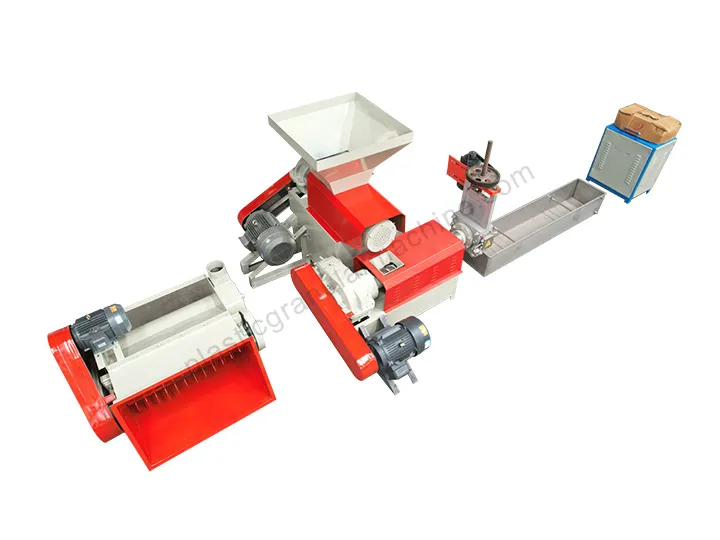

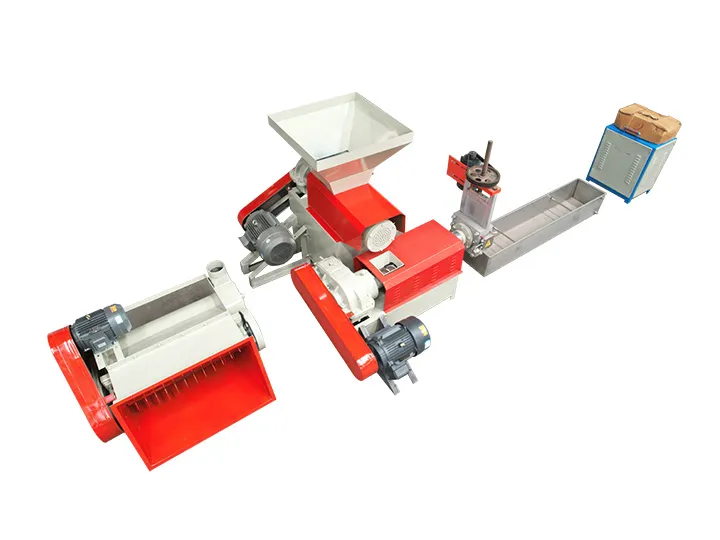

Plastic Foam Granulation

The EPS pelletizing system converts foam into high-quality recycled pellets by melting, extruding, cooling, and pelletizing. This allows it to be recycled in packaging, construction, and other industries.

Choosing Suitable Styrofoam Recycling Machines

After clarifying your production needs, budget, and site size, it is crucial to select the right equipment.

EIFFICIENT can provide customized solutions for small foam recycling plants, offering one-stop service for design, manufacturing, installation, commissioning, and after-sales service. Efficient and high quality to protect your production efficiency.

- A detailed introduction will help you understand the knowledge of foam recycling.

- A Compact design will help you rationally plan the plant area.

- Small capacity models are suitable for small foam recycling factories.

- Professional equipment brings you an efficient production experience and high-quality pellets.

- Timely after-sales service and a one-year free warranty provide reliable protection.

Conclusion

Investing in a small foam recycling plant with less start-up capital and lower operating costs can help you follow the trend of the plastic foam market development and seize the opportunity to realize the double benefit of economy and environmental protection.

EFFICIENT has 14 years of experience in the industry, providing quality EPS recycling solutions to entrepreneurs. Please leave your contact information for detailed equipment information!