Achieve Premium Recycled Plastic Resin Pellets with Our Recycling Machinery

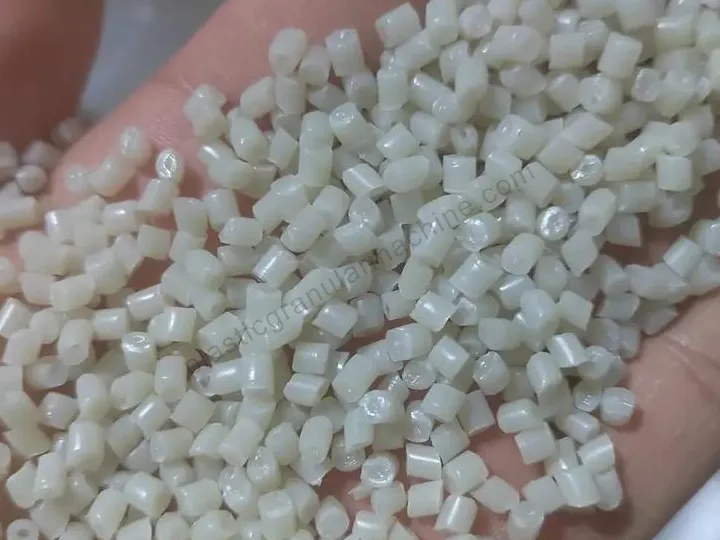

As an important cornerstone of sustainable development, recycled plastic resin pellets are widely used in many fields such as construction, packaging, household, automotive, etc. Their quality directly affects recycled plastic products’ overall performance and reliability, and therefore has significant economic, environmental, and strategic value.

So, for plastic recyclers, what kind of plastic pellets can be produced to increase market competitiveness? And how should they manufactured?

What Are The Characteristics of Premium Recycled Plastic Resin Pellets?

High purity

The purity of high-quality recycled plastic pellets can reach 98%, so they can be easily molded in subsequent processing, and produce stable quality and excellent performance of plastic products. If the impurity content is high, it will affect the strength, appearance, and durability of plastic products.

Consistency

The consistency of plastic pellets is reflected in their size, shape, density, color, and other aspects. The consistency of recycled pellets helps to increase the production speed of plastic products, reduce the scrap rate, and improve the quality stability, and appearance of the products.

Excellent physical properties

High-quality recycled plastic resin pellets should have good and stable physical properties, including impact resistance, tensile strength, bending strength, etc., to ensure the durability of plastic products to meet the high standard of plastic materials required by automotive, construction, and other industries.

High chemical stability

Plastic granules must have good corrosion resistance, UV resistance, oxidation resistance, heat resistance, and other properties to prolong the service life of plastic products, avoid embrittlement or discoloration, and so on.

Batch Stability

Recycled resin pellets from different production batches should have stable and consistent physical and chemical properties to ensure the quality and reliability of the final product.

Batch Stability

Recycled resin pellets from different production batches should have stable and consistent physical and chemical properties to ensure the quality and reliability of the final product.

How To Achieve the Above High Standard of Recycled Plastic Granules?

To realize the production of high-quality recycled plastic resin pellets, it is necessary to strictly control all aspects of the plastic recycling process, which requires the introduction of advanced plastic recycling machines to accurately control the temperature, time, and other core process parameters of plastic recycling.

With 14 years of experience, EFFICIENT, a leading supplier of plastics machinery, offers complete integrated pelletizing systems that include shredding, washing, pelletizing, and drying and is committed to creating the optimal plastic recycling solution for plastic recyclers around the world.

Key Features of Our Recycled Plastic Resin Pellets Making Machines:

Strong crushing: the plastic crusher can continuously and stably crush the waste plastic with the capacity of 100-500kg/h, to ensure the uniformity of the plastic fragments and lay a solid foundation for the subsequent efficient granulation.

High-efficiency impurity removal: through the organic combination of mixing and high-pressure spraying, it efficiently removes the oil, glue, and other stubborn impurities of the plastic, ensuring that the purity of the plastic recycling pellets reaches more than 98%.

Precision granulation: Equipped with an intelligent control cabinet, it can precisely control the temperature, time, pressure, and cooling speed of melting and granulation to ensure the uniformity and stability of recycled plastic resin granules.

Easy to operate: the whole plastic recycling line is highly automated, and the recycling process can be monitored in real-time by the intelligent control system, which is easy to operate and reduces manpower.

Energy saving: With energy-saving motors and optimized process flow, our plastic recycling equipment is environmentally friendly and energy-saving, in line with environmental standards.

Conclusion

If you want to improve the efficiency and quality of plastic recycling, please don’t hesitate to contact us for customized pelletizing solutions. We will help you improve the performance of recycled plastic resin pellets with advanced recycling technology, high-quality equipment performance, and perfect service to enhance market competitiveness and get good economic benefits!