PVC Recycling Machines Boost Economic Circularity In Nigeria

As a rigid plastic recycler, what can you do to improve your recycling business? Recently, a Nigerian customer successfully upgraded his plastic recycling business with our PVC recycling machines.

Opportunities for us to work together

This Nigerian customer owns a small plastic recycling plant in Lagos that collects PP, PE, PVC, and other rigid plastics. With the rapid development of the Nigerian recycled plastic market in recent years, the original equipment could not meet the demand for production upgrades.

The client wants to introduce advanced equipment to improve the efficiency and quality of plastic recycling. Afterward, he learned about our PVC recycling machines and showed great interest in them through various searches and comparisons.

Our Customized PP Recycling Solution for Customer

After receiving the customer’s message on the website, our sales manager contacted and consulted on his needs for the first time. According to the customer’s budget, production scale, the desired finished product effect, and other information, we finally designed a set of customized hard plastic crushing and washing programs for him, which perfectly fit the customer’s needs. The key features of our HDPE PVC recycling machines are as follows:

- Cost-effective: Customized crushing and cleaning solutions to meet customer needs and achieve efficient use of resources.

- High-efficiency: 600-800kg/h capacity can greatly improve PP recycling efficiency, and efficiently help enterprises to upgrade their production scale.

- Good recycling effect: equipped with powerful motor, scientific design, plus multiple efficient cleaning, can ensure the realization of continuous, uniform, high-purity plastic chips production, providing high-quality raw materials for plastic pelletizing.

- Durable: Made of high-quality stainless steel material, ISO and CE certificates are available, and our PVC recycling machines are abrasion-resistant, corrosion-resistant, and heat-resistant.

- Energy Saving: Recycling water design and adjustable frequency converter motor speed to reduce unnecessary energy consumption.

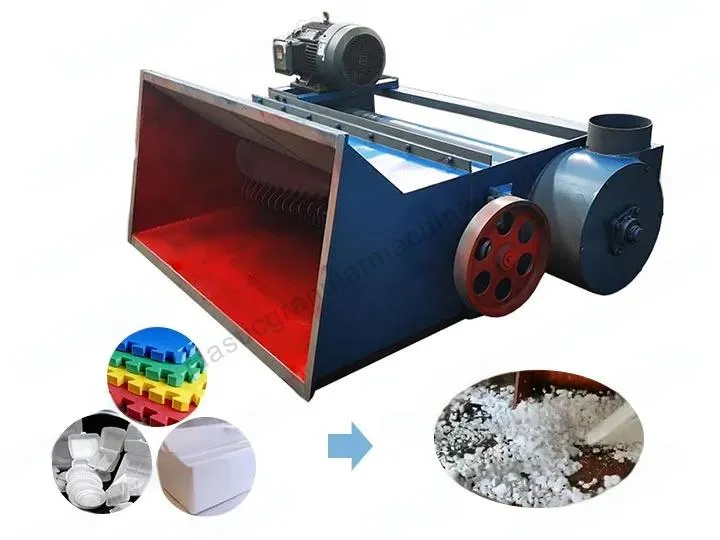

Details of Our PVC Recycling Machines

| Name | Techincal Data |

| Plastic cruher | Model: SL-600 Capacity: 600-800kg/h Motor Power: 15KW Blades Number: 6 moving knives and 4 fixed knives |

| Screw Washing Machine | Power: 3KW Length: 3m Diameter: 325mm |

| Automatic Sharping Machine | Model: SL-1000 Power: 2.2kw Size: 1200*800*1200mm |

| Plastic Washing Machine | Length: 5m Width: 1.3m Height: 1.2m Power: 2.2kw |

| Vertical hoister machine | Power: 7.5kw Diameter: 530mm |

| Plastic Dryer Machine | Model: SL-500 Power: 11kw Length: 2.5m |

| Electric control cabinet | Function: Control crushing and washing process |

Positive Feedback From Our Nigerian Client

After efficient international logistics and installation by our technical team, the PVC recycling machines are now successfully manufactured, delivered, and quickly put into plastic recycling.

“My plastic recycling is going very well and the overall recycling efficiency has increased by about 30%! EFFICIENT is really a reliable and quality partner and I look forward to more cooperation in the future!” The customer gave such a high rating. We thank you for your kind comments and wish you a successful plastic recycling business!

Our Growth in Nigeria’s Recycling Market

Previously, we have successfully exported plastic shredders, granulators, PET washing lines, etc. to Nigeria many times to help upgrade the local plastic recycling industry and promote the development of the circular economy.

This successful partnership with Nigerian customers enhances EFFICIENT’s business growth in the plastic recycling sector and significantly boosts its competitiveness in the market. We look forward to collaborating with more local companies in the future to jointly promote the sustainable development of the plastic recycling industry in Nigeria!

Conclusion

Rigid plastic crushers and washing machines provide high-quality raw materials for pelletizing. If you are interested, please feel free to contact us!