Efficient PVC Pulverizer: Grind Plastic Pellets Into Fine Powder

Do you want to grind recycled plastic pellets into fine powder? Our PVC pulverizer machine can be applied to various plastic raw materials such as PP, PE, PVC, HDPE, etc. We provide you with efficient and advanced plastic grinding solutions.

The Function Of Plastic Pellet Grinder

Provide high-quality plastic processing raw materials: Use the plastic mill to process plastics into different finenesses of powder, which can provide suitable plastic raw materials for the subsequent injection molding, blow molding, etc., and improve the quality and performance of plastic products.

Convenient for plastic modification: Modified materials can be added and mixed with the plastic granules, thus realizing the modification of recycled plastic granules to improve the strength, heat resistance, etc.

Improve production efficiency: The smaller particle size of plastic powder makes it easier to melt, which is suitable for production scenarios that require rapid processing.

Why Choose Our PVC Powder Making Machine?

1. The particle size of plastic powder can be flexibly adjusted according to the production needs. The powder quality is fine and uniform, which can meet different production scenarios.

2. Wide application: Our PVC pulverizer not only can grind PVC plastic but also can be used for PP, PE, ABS, HDPE, and other plastic materials.

3. High efficiency: Depending on the production scale, the appropriate PVC pulverizer machine can be selected. This setup includes a high-efficiency motor, ensuring both high efficiency and low energy consumption.

4. Reasonable structure design makes the PVC pulverizer easy to clean and maintain, and convenient to replace the knives and other wearing parts.

5. The plastic grinding process is entirely enclosed, preventing dust escape. It is equipped with dust removal equipment, ensuring production meets environmental standards and avoids polluting the environment.

How does A PVC Pulverizer Machine work?

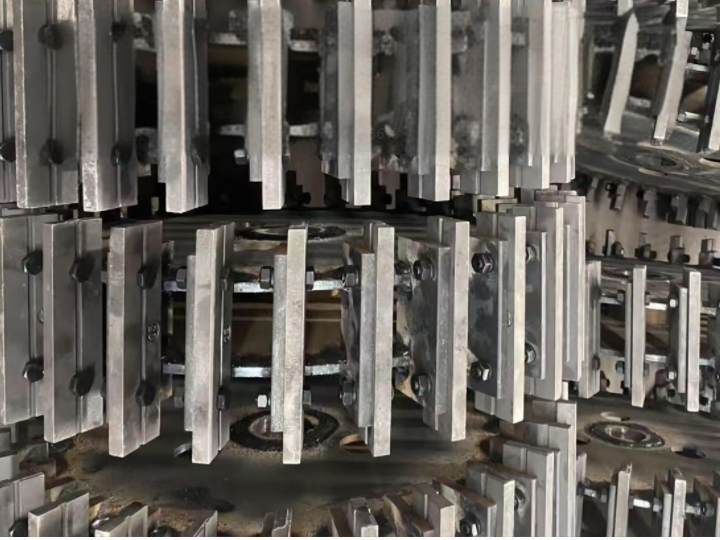

The PVC scrap pulverizer machine includes a main motor, fan, shut-off fan, vibrating screen, cyclone, intelligent control cabinet, cutter, and bag dust removal system.

Feeding: First, the plastic granules or plastic chips enter the grinding chamber of the plastic granulator through the feed inlet.

Grinding: The motor generates significant power to rotate the knives within the grinding chamber. The combination of moving and fixed knives enables efficient grinding of plastic.

Conveying: The fan generates an airflow that conveys plastic powder to the cyclone for separation. The plastic powder that meets the requirements is collected, while the excess returns to the grinding chamber for further processing.

Screening: The vibrating screen further sieves the plastic powder of different particle sizes.

Collection: The final finished plastic powder is discharged through a shut-off fan for collection. Dedusting system to reduce dust pollution

Through the synergy of all components, we can realize an efficient and environmentally friendly plastic grinding process.

Parameters Of The 300KG/H PVC Pulverizer Machine

Take the recently customized 300kg/h PVC grinder as an example to show its parameters for reference.

| Name | PVC Pilverizer |

| Capacity | 250-300kg/h |

| Motor Power | 55KW |

| Fan power | 5.5KW |

| Blades Number | 25 rotating blades, 14.4 fixed blades. |

| Weight | 1650KG |

| Size | 2300*1600*3600mm |

| Mainframe RPM | 2900RPM |

Conclusion

Our PVC milling machine is widely praised for its high quality, high efficiency, and perfect after-sales service. The above customized plastic powder making machine for a customer has already gone through a trial run and received positive feedback from our client.

The perfect match between a PVC grinding machine and a plastic granulator can help plastic recycling enterprises improve recycling efficiency, reduce costs, and increase efficiency. If you are interested, please feel free to contact us!