Polystyrene Shredder and EPS Densifier Installed In Malaysia Works Well

Polystyrene shredder and densifier: In the pre-processing process before foam granulation, large pieces of EPS foam are crushed and melted into dense lumps in one step, reducing the volume and subsequent processing difficulties to promote recycling efficiency! Not long ago, we sold such a 200 kg/h EPS crusher and styrofoam melter to Malaysia and received positive feedback from our customer!

The Background of Our Customer

In recent years, the foam recycling industry in Malaysia has been growing rapidly, driven by technological innovation and strong government support. In this context, one of our Malaysian customers, an EPS styrofoam recycler, is planning to introduce advanced polystyrene recycling equipment to optimize recycling efficiency to enhance market competitiveness, expand international cooperation opportunities, and increase business scale.

After many comparisons and research, he was attracted by EFFICIENT’s EPS recycling line and its successful export cases to Malaysia and took the initiative to leave a message inquiring about the quotation and equipment suggestions.

Our Solution

After receiving the customer’s inquiry, our sales manager first contacted the client to understand his production situation and specific needs in detail. Considering the customer’s existing equipment, the sales manager suggests that the customer prioritize the purchase of a polystyrene shredder and EPS styrofoam densifier to improve plastic foam recycling efficiency at the source, while taking into account budget control to ensure that the return on investment is maximized.

Advantages of Our Polystyrene Shredder&Melter

- High Efficiency: The polystyrene shredder and densifier machine adopts an integrated design, integrating foam crushing and hot melting, reducing the intermediate material transfer link and improving EPS recycling efficiency.

- Good Results: efficiently convert the waste foam into dense lumps, greatly reduce the volume of plastic foam, easy for subsequent storage or processing.

- Reduce Manpower: save manpower through highly automated, continuous processing processes, reduce manual intervention, and save manpower cost.

- Strong Applicability: Our EPS crusher hot melt machine can be applied to EPS, EPE, XPS, EPP, and many other different plastic foams. Besides, a variety of models can be selected to meet the needs of different scales of production.

- Good Durability: Adopting high-quality stainless steel materials, anti-corrosion, and high-temperature resistance, which can ensure the long service life of the equipment.

Project Implementation Process

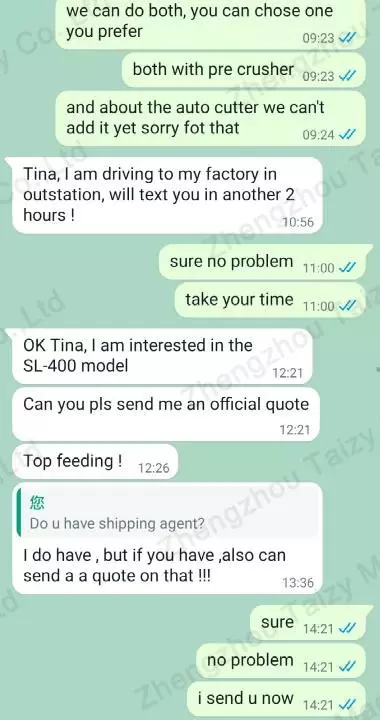

According to the customer’s needs, our sales manager recommends the right type of polystyrene shredder densifier machine and sends detailed related resources including pictures, videos, cases, etc.

After the customer expressed his satisfaction, the sales manager started to finalize more details with him, such as color, material, etc., and designed a customized styrofoam recycling solution for him.

After the equipment was completed and debugged several times to ensure that there was no error, the equipment was delivered to the customer through international logistics to achieve high efficiency.

When the equipment was shipped, our technical team also went to Malaysia to help the customer install the equipment and provide technical guidance so that the equipment could be put into production as soon as possible.

We promise a one-year free warranty and lifetime spare parts supply! If there is any problem with the equipment, we will solve it soon!

Feedback from Our Malaysian Client

The polystyrene shredder and melting machine exported to Malaysia has been running stably, performing as expected, and achieving good results. The customer highly appreciates the innovation and practicality of the machine, saying that its integrated design not only optimizes the EPS foam recycling process and significantly improves the recycling efficiency, but also has excellent cost performance.

Conclusion

The foam crusher sold to Malaysia integrates the two functions of crushing and hot melting, making the pre-treatment of styrofoam recycling efficient and convenient, and promoting the efficiency and quality of recycling. Please get in touch with us if you are also looking for a suitable foam recycling solution!