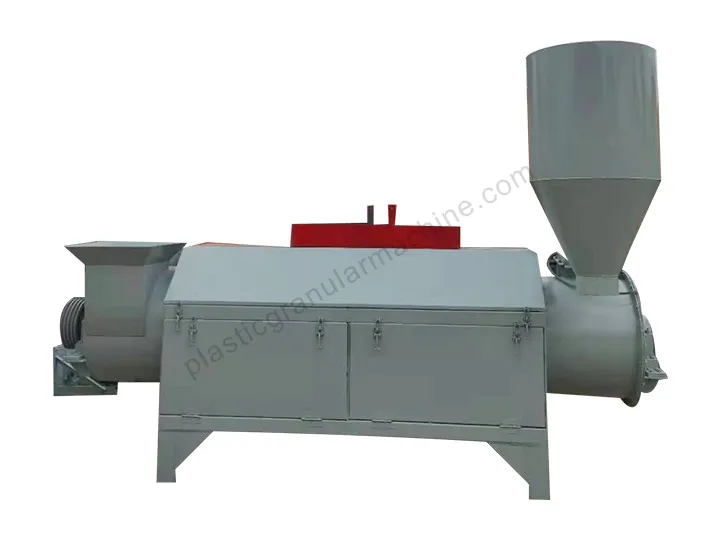

Plastic Drying Machine for Sale

The plastic drying machine adopts the principle of spiral extrusion dehydration to dewater the plastic film. The plastic film dryer machine is equipped with an advanced oil pressure device and a special PLC touchscreen control cabinet. The screw extrusion dehydration structure design is adopted, and the special electric box is equipped. The hydraulic induction type opening can actually control the dehydration effect freely.

Scope of application

Used for dehydration of plastic film, plastic bags, snake bags, space bags, and thin soft plastic.

What are the characteristics of Efficient plastic drying machine?

The operation is simple and the squeezing effect is good. The plastic dryer machine solves the problem of difficult dehydration of soft plastics such as plastic PE film, PE plastic bags, PP snakeskin bags, and plastic greenhouse film. It is indispensable new equipment in the process of breaking, cleaning, and recycling waste plastic films and woven bags.

Advantages of plastic film dryer machine

- The screw extrusion dehydration principle is adopted to solve the problem of difficult dehydration of traditional soft film or filamentous plastics.

- The squeezing dehydration effect of the plastic drying machine is good, and the dehydration rate is more than 90%.

- Made in China, cost-effective.

- Compared with the original hot air drying, mechanical extrusion dehydration can greatly save the use cost.

- It can be customized according to customer requirements