How Does the Styrofoam Compactor Machine Work?

Now styrofoam compactor machine is our company’s best-selling foam recycling machine. Because of global attention to environmental protection, the EPS foam recycling industry has become more and more popular.

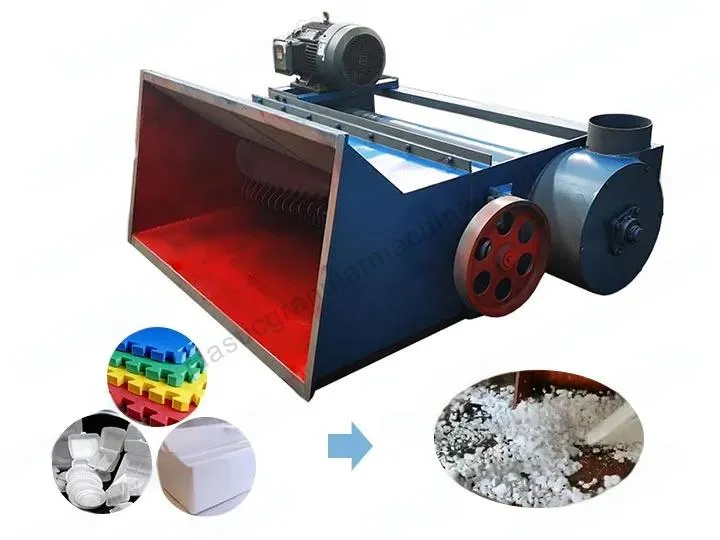

What is a styrofoam compactor machine?

Because the density of the plastic foam is low. This causes it to not be collected well. However, the density of foam after processing by EPS compactor will be greatly reduced. In general, the density of materials will change from 30 kg/m3 to 330 kg/m3. This can greatly facilitate transportation.

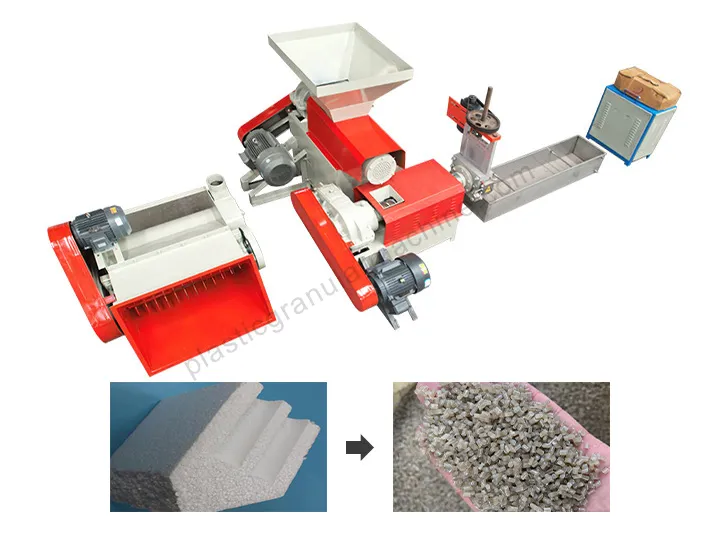

Working principle of the machine

First, the volume of materials will be reduced through the filter screen on the crusher and eps compactor machine. And then these materials will fall onto the screw. The main motor of the foam compactor will push the material forward through the screw. At the same time, the hydraulic system of the die head will compress EPS foam material. Then these eps foam will become blocky, and the volume will be correspondingly reduced by 30 to 50 times.

Features of Efficient EPS compactor

- The styrofoam compactor machine of Efficient Plastic Recycling Machinery can effectively reduce the size of EPS foam, and the compression ratio can reach 1:30-1:50.

- The compressed finished product is an EPS foam plastic block, and its density can reach 330kg/m3.

- Through continuous improvement of the machine, the performance of the EPS styrofoam recycling compactor of Efficient Machinery has been greatly improved.

- Our EPS foam compactor is based on PLC automatic control system and peripheral circuit control, and its performance is very stable.

- EPS foam processed by a styrofoam compactor machine is easy to carry and transport.

- All parts of the machine are composed of one machine, saving cost, energy loss, and space.