The differences and uses of EPS, EPE, and EPP

In our daily life, we will see the words EPE, EPS, EPP, etc. from time to time. So do you know what these materials are? Next, we will take you to understand the 3 common packaging cushioning materials commonly used in the market.

EPS foam

First of all, the early entry into the packaging market is EPS, Expandable + Polystyrene = Expanded Polystyrene, or EPS for short, the official name of this material is polystyrene EPS. The density is much lighter than other materials. This saves material costs. The disadvantage is that EPS needs to be molded, which is suitable for all kinds of packaging with high demand and complex shapes. As you know, once the mold is opened, if you want to change the shape, it is very troublesome to modify the mold. Or if you change too much, we can’t use the original mold anymore. In this era of rapid changes, this kind of unchanging shape is obviously not adaptable.

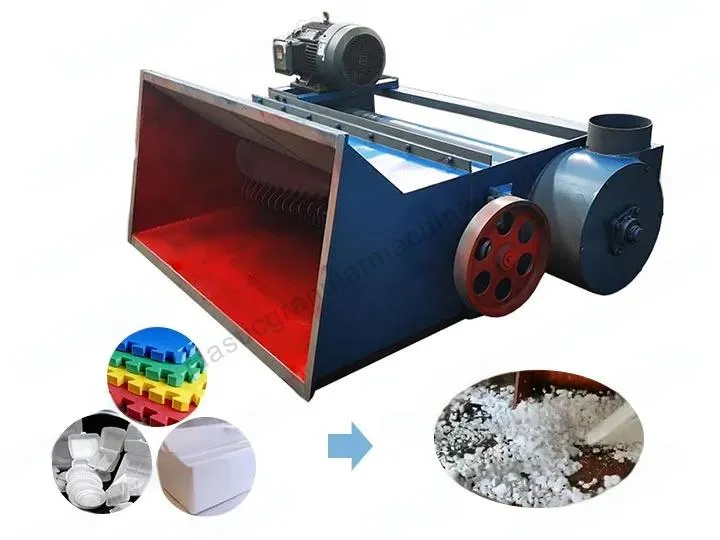

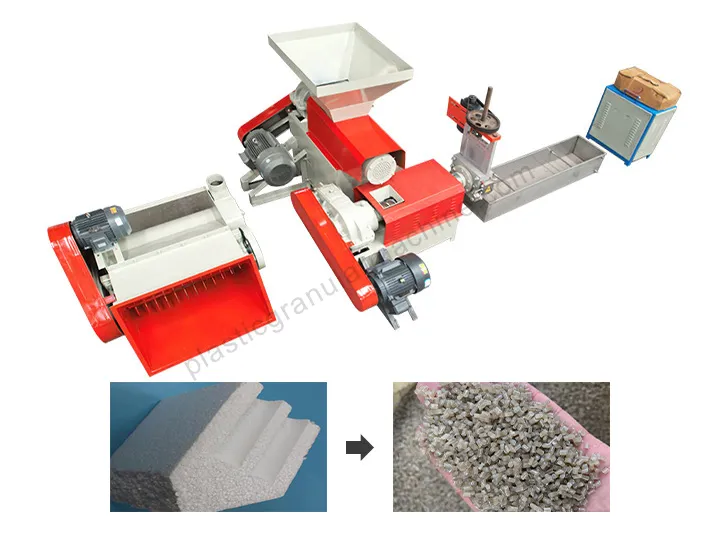

Moreover, EPS foam is white vacuum molding. The degradability of this material is very low, which has a great impact on the environment. Therefore, many countries that promote environmental protection are using EPS recycling machines to recycle EPS foam.

EPE foam

EPE is officially known as Expanded Polyethylene. This material because it overcomes the shortcomings of ordinary styrofoam EPS fragile, deformation. It has many advantages such as water and moisture barrier, shockproof, sound insulation, heat preservation, and environmental protection. Also has good chemical resistance. Therefore it is an ideal substitute for traditional packaging materials. It is widely used in the packaging of many products such as electronic appliances, instruments and meters, computers, lighting, and so on.

In addition, it only needs cutting and knife mold for molding. The cost of production molding is relatively low. Style change is easy to do. The disadvantage is that the same volume of material is heavier and more costly than EPS.

EPP foam

Another type of packaging material is EPP, which stands for Expanded Polypropylene. This is the abbreviation for a new type of foam, EPP is a polypropylene plastic foam. It is also a crystalline polymer composite with relatively high performance. EPP is a material similar to EPS in terms of molding and performance. But the performance of the material is close to EPE pearl cotton, but it is better than EPS elasticity.

EPP is also an environmentally friendly material that can be recycled, can be naturally degraded, and will not cause white pollution. We often use EPP materials in automobiles, such as bumper cores, bumper blocks, roof liners, door fillers, headrests, sun visors, and so on. EPP has been widely used in the packaging industry, such as electronic products, medical devices, etc.

Summary

The above is the introduction of these three packaging materials, if you need other plastic recycling equipment, welcome to contact us at any time.