A Deep Dive To Explore Polyster Fiber Recycling

Polyester, a synthetic fiber that can be made from PET, is commonly used in our daily lives because of its durability and wrinkle-resistant properties. However, its extensive use contributes to significant environmental pollution. This post explains polyester fiber recycling, reusing, and reducing in detail.

What’s the Significance of Polyester Fiber Recycling?

Polyester fibers are important in our daily lives as the main component of clothing and technical textiles. The importance of recycling polyester fibers includes but is not limited to, the following:

- Promote Ecological Civilization: Reducing plastic waste in landfills helps reduce land pollution and protect the environment.

- Cost Saving: By recycling polyester fiber, the production of new polyester fiber is reduced, thus lowering costs.

- Expanding Applications: By adding chemical reagents to the recycling process, the material can be modified to improve creep resistance and other properties, giving the discarded polyester fiber a wider range of applications.

How Can We Process Polyester Fiber into Recycled Materials?

The complicated recycling process can be divided into five steps: collection, shredding, washing, and drying.

Step1: Collection:

Polyester fibers are commonly used to make clothing or technical textiles, and the following materials can be collected for recycling:

- Waste clothing

- car seats

- construction materials

- factory trimmings

- waste fibers and rejects

Step2: Crushing:

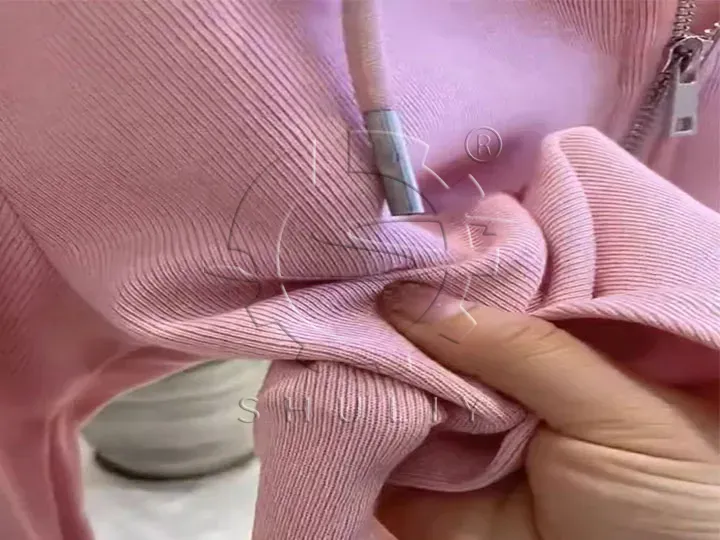

Plastic crushers are used to cut large plastic fibers into small pieces, increasing the surface area of the material for subsequent washing and processing. The shuliy crushers are made of high-quality stainless steel, which features durable and corrosion-resistant.

Step3: Washing:

Efficient recommends using a three-stage cleaning method in the PET washing process.

- First of all, the friction washing machine through the friction principle of the initial removal of raw materials on the label, stains, and other impurities;

- The sink float separation tank separates PET bottles and further washes them with different densities.

- Finally, the hot washing tank removes the glue, oil, grease, and other stubborn impurities through high-temperature digestion.

Step4: Drying:

The last step, using plastic dryer machines to dewater plastic fibers. If your output is large, you can also add the dryer tube to your recycling plant.

Challenges and Opportunities of Polyester Recycling

Challenges:

Polyester fibers also face several challenges in the recycling process, including:

- Textiles are often mixed with other materials, making recycling difficult.

- Recycled polyester fibers are not as high quality as virgin polyester and are often blended with new materials to maximize results when making new products.

Opportunities:

Despite some challenges, there are still significant opportunities for polyester fiber recycling:

- As technology develops, recycling processes will become more efficient and cost-effective.

- People are becoming more environmentally conscious, making it easier to recycle post-consumer PET.

Summary

In short, polyester fiber recycling facilitates environmental protection and benefits us. Believe that we can create a sustainable future for PET! If you’re interested, please don’t hesitate to join us. Efficient is by your side.