PET Granules Making Machine Run Successfully in South Sudan 2024

Efficient helped introduce a PET granules making machine to a South Sudanese customer, allowing the company to not only successfully solve the problem of waste plastic bottle accumulation, but also create new economic value by recycling and reusing these materials.

This case demonstrates the key role of plastic recycling equipment in reducing environmental pollution, improving business profitability and promoting a circular economy.

Why Did South Sudan Customer Need PET Granules Making Machine?

For beer and drinking water bottle recycling.

In South Sudan, a local company is mainly engaged in the production of bottled drinking water and bottled beer. However, as their business expanded, they faced a problem: a large number of used plastic bottles (mainly drinking water bottles and wine bottles) were piling up, wasting resources and taking up space in their warehouse. In order to improve resource utilization and at the same time open up a new source of income, they decided to set up their own plastic recycling plant to turn used bottles into economically viable PET granules.

They realized that recycling these PET plastic bottles into plastic pellets and selling them to other countries was a very economically viable business model.

Installment and Operation of PET Recycling Factory

In order to achieve their goals, the company decided to import our plastic bottle recycling line. The recycling line is specifically designed to handle PET plastic bottles and is able to process them in the following steps:

PET bottle label removal: Before shredding the bottles, they should separate the PVC labels from PET bottles.

Cleaning: removes labels, stains and other impurities from the bottles to ensure that the plastic material is clean and free from contamination.

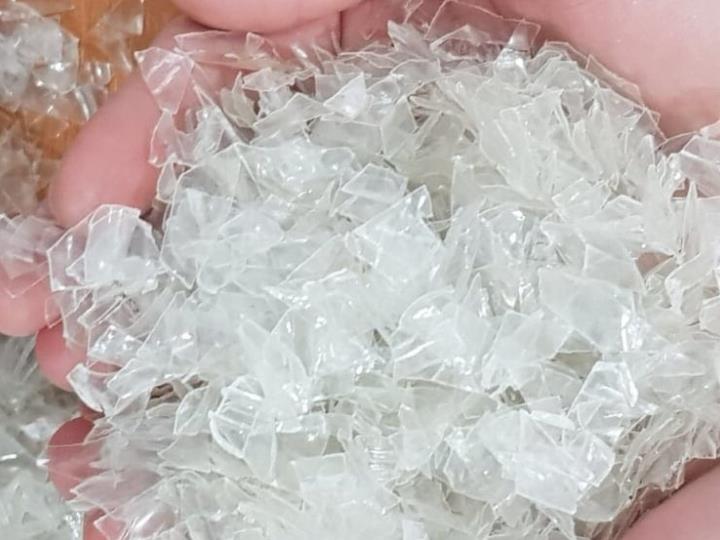

Pelletizing: The cleaned plastic pieces are heated and melted by a PET granules making machine, then extruded and cut into uniform PET granules.