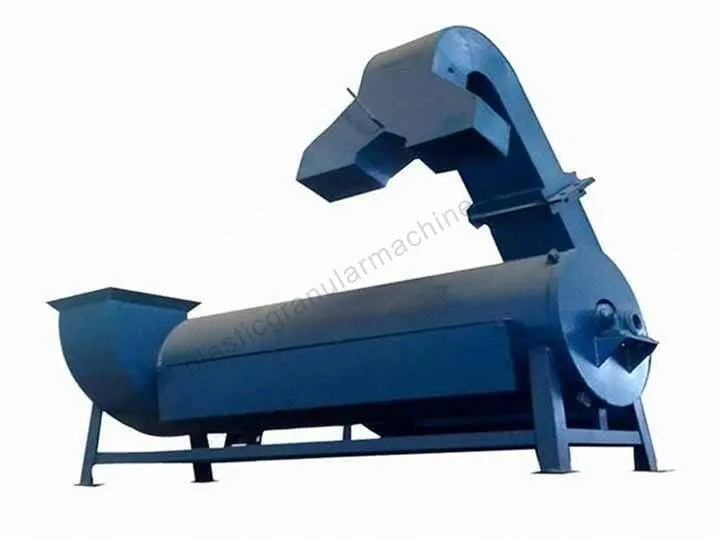

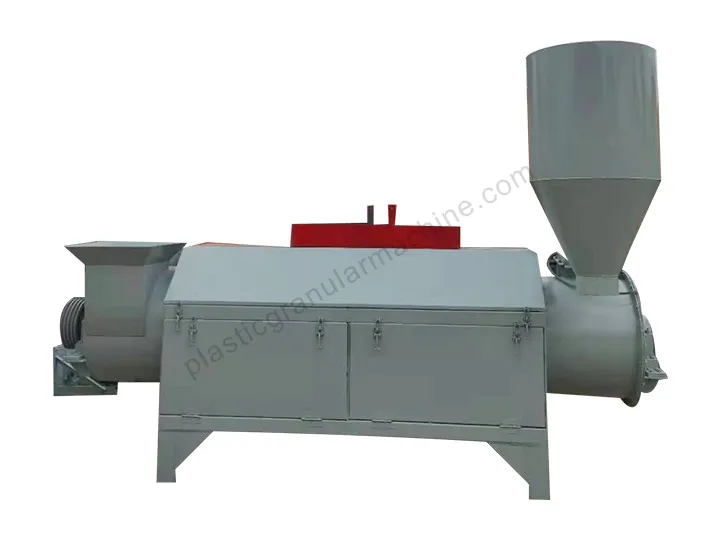

Horizontal Pet Flakes Dryer | Plastic Chips Dryer Machine

| Model | 500 |

| Power | 7.5kw |

| Size | 2854*902*1750 (mm) |

| Weight | 350kg |

You can now ask our project managers for technical details

PET flakes dryer is the last major step in the plastic bottle recycling line. It is a machine placed behind the plastic washing machine. With the help of a PET bottle flakes dryer, the dehydration rate of plastic flakes is as high as 97%.

How does the PET flakes dryer work?

The dryer machine completes the dehydration process in the order of spiral moving, separation dehydration, automatic feeding, and automatic discharging. Then plastic flakes are washed out of the rinsing tank and directly enter the feed hopper of the dehydrator. Driven by the motor, the spindle of the horizontal dehydrator rotates at high speed. Thus, the plastic bottle fragments are driven to rotate at a high speed. Then the plastic fragments are dried by centrifugal force. At the same time, the blade with a certain included angle pushes the plastic bottle piece to the discharge port.

Therefore, a PET bottle scrap dryer is one of the ideal equipment in plastic processing machinery. It can be used with the whole PET plastic bottle cleaning line, or it can be used alone.

Product features

- Widely used. The PET flakes dryer can dehydrate PP plastic chips, PE plastic chips, and PET plastic scrap.

- High dehydration rate. Because the dehydration rate of the machine is over 97%.

- The machine consumes less power.

- The plastic chips dryer machine has a high degree of automation, which can greatly reduce labor intensity.

- Advanced technology. Low wear and noise

- Advanced design. The double outlet design saves time and effort.

- The structure of the plastic chips dryer machine is simple. Therefore, the disassembly and assembly of the machine are very convenient and easy to clean.

Parameters of PET chips dryer machine

| Model | 500 |

| Powder | 7.5kw |

| Size | 2845*902*1750(mm) |

| Weight | 350kg |

What are pet flakes used for?

- Make plastic bottles. We all know that recycled plastics cannot come into direct contact with food. But we can use it as the middle layer of plastic bottles.

- Make bedding. Recycled PET chips can be made into sleeping bags, pillows, blankets, mattresses, and other items.

- In addition, plastic scrap can also be made into mobile phone shells, sunglasses, plastic electrical appliance shells, industrial injection molding accessories, etc. It can also be used to make plastic chairs, building blocks, and set-top boxes.

PET flakes dryer for sale

At Efficient machinery, we have two different types of plastic scrap dryer machine for sale: vertical and horizontal dryers. So, you can choose different types of dryers according to your needs. Importantly, we can customize the machine according to your needs. Therefore, if you want to buy a PET flakes dryer that meets your needs, please contact us at any time.