How to Solve Styrofoam Compactor Problems in Russia’s Extreme Cold?

Russia is located in a high-latitude region with a cold and harsh winter climate. When recycling plastic foams, styrofoam compactor may face some issues such as hardening of the polystyrene, difficulty in starting the engine, etc. This article provides specific solutions for using EPS briquetting machines in Russia for extremely cold environments.

Common Issues with Styrofoam Compactors Due to Extreme Cold

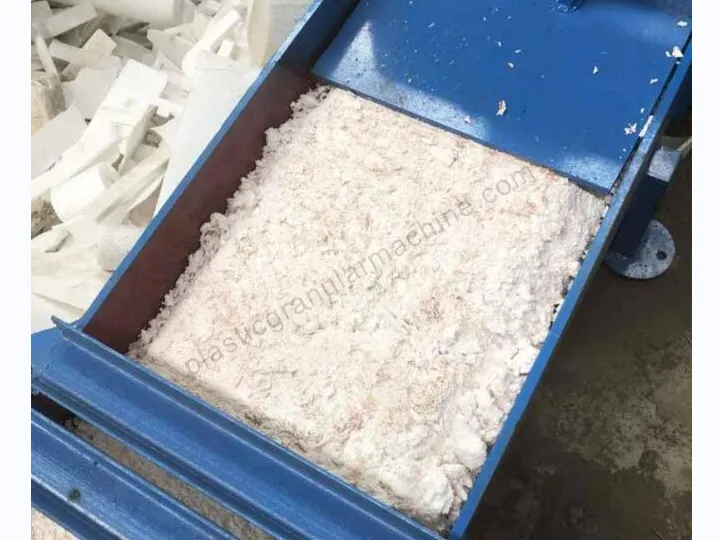

Foam Properties Change: Plastic foams become brittle, less elastic, more rigid, and less easily deformed in icy environments. As a result, foam compression becomes more difficult, affecting the foam cold press’s effectiveness and recovery efficiency.

Decreased hydraulic system capacity: At low temperatures, hydraulic oil viscosity increases and fluidity decreases, resulting in decreased hydraulic efficiency and insufficient compression force.

Failure of parts: some key metal parts such as transmission chains may be brittle in low temperatures, and impact resistance, and durability are reduced, resulting in cracks, damage, etc., leading to equipment failure, and affecting the operation of foam cold press.

Damage to sealing materials: Rubber and other sealing materials will become brittle, harden, and lose elasticity in very cold weather, leading to a decrease in sealing performance, hydraulic oil leakage, and other problems, which will pollute the foam raw materials and the environment.

Wiring failure: The insulation of wires may be reduced, resulting in safety hazards such as electric leakage. At the same time, due to thermal expansion and contraction, the connecting parts of the wire may become loose, affecting the stability of the electrical connection of the foam cold press.

Failure of electrical components: Sensors, controllers, and other electronic components may be more sensitive to temperature and their performance may be unstable in extremely cold environments such as the Russian winter, affecting the automated control and detection functions of the equipment.

Difficulty in starting the engine: the lubricating oil becomes hard and the resistance of the engine coil increases under the influence of low temperature, which may affect the normal starting of the engine.

How To Solve These Problems?

- Foam pre-treatment: Pre-heat the foam with a heater or equip the conveyor with electrical heating or insulation.

- Optimize hydraulic system: Use low-temperature hydraulic oil suitable for low-temperature environments or add heaters to ensure the foam cold press maintains good flow and lubrication even in extremely cold environments.

- Protect parts: Select low-temperature, corrosion-resistant, high-quality steel for the foam cold press to improve the impact resistance and toughness of the equipment. In addition, parts should be inspected and replaced regularly.

- Electrical Protection: Install anti-freeze protection devices for the electrical components of the equipment, and ensure the sealing and waterproofing of the electrical wiring.

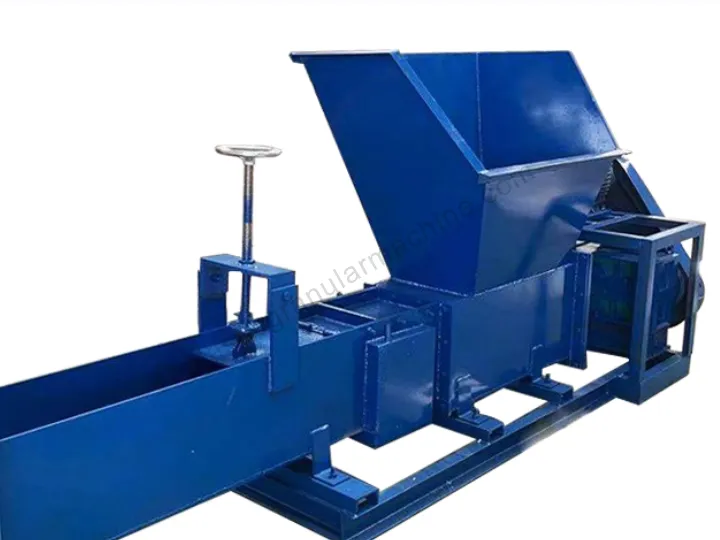

Polystyrene Compactor for use in Russia

Foam cold press operation under extremely cold conditions requires targeted optimization design, therefore, choosing a high-quality foam cold press can fundamentally and effectively avoid foam hardening, machine clogging, equipment loss, etc.

EFFICIENT, as a professional foam recycling expert, is committed to providing customers with efficient and stable cold press solutions, and according to the needs of extreme environments, customized and appropriate equipment design and technical support for your foam recycling work.

- Made of high-quality stainless steel, our foam cold press has high strength, abrasion resistance, and corrosion resistance, and is not easily brittle.

- Excellent manufacturing process, solid welding, high assembly precision, and many trial verifications before delivery to ensure stable operation of the machine.

- Equipped with a powerful motor, it can realize foam cold pressing efficiently, and the compression ratio is 40:1.

- Provide perfect after-sales service, we offer technical support, operation tutorials, as well a one-year free warranty, etc., for your peace of mind production guarantee.

Overcoming Extreme Cold: Successful Foam Cold Press Cases

A Russian building materials plant installed a specially modified and customized Shuliy foam cold press to maintain consistent production in an extremely cold environment. We upgraded key parts with low-temperature-resistant materials.

The machine is equipped with advanced heating modules and an intelligent control system for real-time monitoring and dynamic adjustment of temperatures.

After the upgrade, the foam cold press operates smoothly under extreme cold conditions, with high capacity and energy consumption controlled within reasonable limits, improving the plant’s foam recovery efficiency.

Conclusion

Conventional foam cold presses can experience a variety of problems in extremely cold environments. Understanding, solving and learning to avoid these problems can help us improve foam recovery efficiency and increase market competitiveness. If you are interested in the foam cold press, please contact us!