Is A Plastic Drum Shredder Worth The Investment?

The plastic drum shredder is essential for rigid plastic production and recycling. Is it worthwhile to purchase an HDPE crusher, and how should one invest in it? This article will analyze these points, which I hope will be helpful:

- The role of plastic barrel shredders in industrial recycling.

- The cost of the plastic drum crushers.

- The actual operation effect of plastic crushing machines.

What Is A Plastic Drum Shredder And What Role Does It Serve?

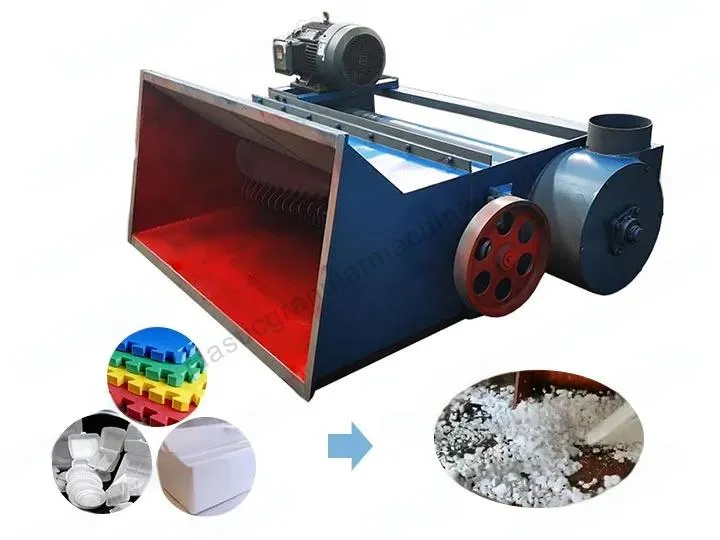

The plastic drum crusher is used in industry to crush hard plastic into small, uniform pieces for further processing and granulation. This process also facilitates convenient storage and transportation.

It can not only be used to process HDPE drums but also can be applied to PVC, PP, PE, ABS, composite materials, etc., which can effectively improve the plastic recycling efficiency.

Whether it is post-industrial internal recycling or post-consumer plastic waste, the automatic plastic shredding machine can crush it rapidly, reducing labor consumption and avoiding production hazards.

In addition, the plastic crusher makes it easier to recycle discarded plastic, reducing the amount of plastic entering landfills and oceans, promoting economic cycles, and protecting the environment.

How much does a plastic crushing machine cost?

The cost of investing in a plastic drum shredder should be considered in terms of the purchase price, operation and maintenance costs, and production efficiency.

Plastic crusher machine cost

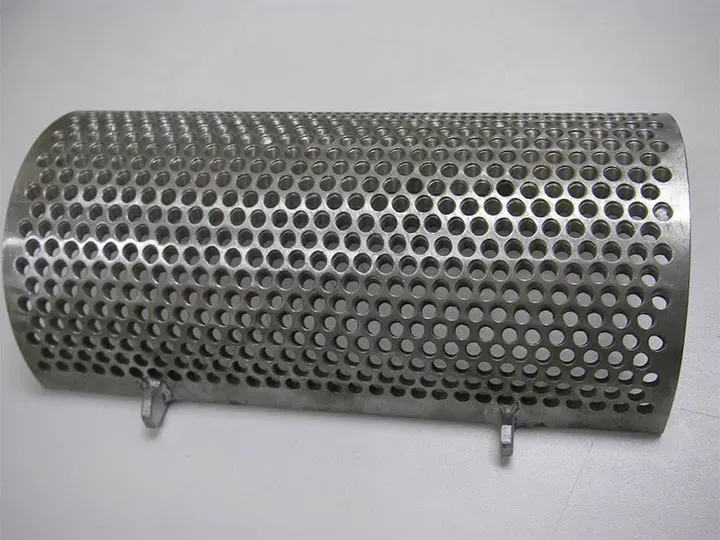

The plastic barrel shredder usually includes the main machine, motor, blades, screens, and so on. Blade materials, number of the crusher parts, motor power, and the plastic shredder sizes will affect the price of the crusher, ranging from $1000 to $3000.

- The price of common material is lower than the price of stainless steel lower than the price of high-quality alloy, but their corresponding abrasion resistance, corrosion resistance, etc. also increase in turn;

- The number of blades and screens depends on your production needs. If you have a sufficient budget, you can also buy supporting the winch and lifting machine, which is more conducive to systematized production;

- The output of the plastic Drum shredder ranges from 400-2000kg/h. The higher the output, the lower the price.

Please contact us for specific price details, we can provide you with a reference!

Operating cost of the plastic chipper

The operating cost of a plastic crusher is mainly reflected in the energy consumption, daily maintenance costs, and labor costs. Choosing a durable plastic crusher with after-sales service will reduce operating costs.

Operational benefits of the plastic drum crusher

The economic benefits of the plastic drum shredder can be realized by selling recycled final products or reducing new plastic production costs.

The price of recycled plastics varies from region to region, you can conduct market research or contact us for details.

Invest in a reliable and efficient Plastic Drum Shredder

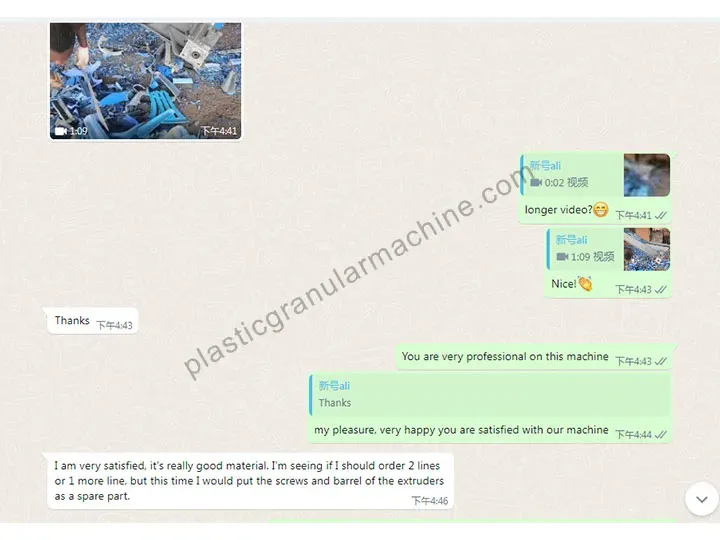

If you are looking for a suitable plastic crusher, we recommend our crusher, which is famous for high efficiency, low energy consumption, no jamming, and low noise. If you have special production needs, we can also provide customized machines.

Meanwhile, as a plastic recycling expert, we provide a complete after-sales service guarantee, including technical support, door-to-door installation, and a one-year warranty. Here are some of our cases:

- Plastic Crushing Machine in Nigeria Solves Blockage Issues

- HDPE granules manufacturing process feedback in Côte d’Ivoire

Summary

It is worthwhile to invest in a plastic drum shredder. It not only promotes recycling efficiency and reduces costs, but it also protects the environment and enhances your company’s green corporate image.

We offer a variety of models of plastic drum shredder, please tell us your production needs, and we will provide you with the most suitable crushing program!